Feb 26 2016

The versatile potential of the wonder material graphene, a modified version of carbon, has been widely explored in numerous fields, including electronic switches and coating machine components.

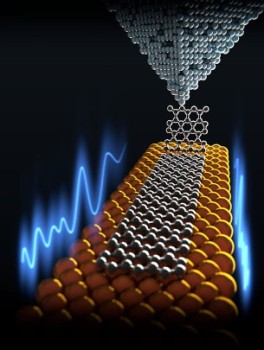

A graphen nanoribbon was anchored at the tip of a atomic force microscope and dragged over a gold surface. The observed friction force was extremely low. (Image: University of Basel, Department of Physics)

A graphen nanoribbon was anchored at the tip of a atomic force microscope and dragged over a gold surface. The observed friction force was extremely low. (Image: University of Basel, Department of Physics)

A team of physicists at the University of Basel led a collaborative group of international researchers to study graphene’s lubricity on the nanometer scale.

According to the research report, published in the Science journal, graphene was chosen as it only produces minimal friction, so it could significantly reduce the loss of energy in machines when applied as a coating.

Graphene may be adopted as an extremely thin coating in the future, which could result in very limited energy loss between mechanical parts. This is due to the extraordinarily high lubricity, or the superlubricity of modified versions of carbon in the form of graphene.

When this property is applied to mechanical and electromechanical devices, it improves energy efficiency, and also significantly prolongs the service life of the device. A team from the University of Basel and the Empa researched graphen’s above-average lubricity, using a method involving experimentation and computation. 2D strips of carbon atoms, also known as graphene nanoribbons, were fastened to a sharp tip and hauled across a gold surface. The interactions between the surfaces during the movement were examined using computer-based calculations. The research team, led by Prof. Ernst Meyer at the University of Basel, hope that this method would help them understand the causes of superlubricity. Until now, not much research has been performed in this area.

The researchers anticipate that by examining the graphene ribbons, they could learn more than just the slip behavior. Measuring the mechanical properties of the carbon-based material would also be useful as it would provide exceptional potential for numerous applications in the field of micromechanical switches or coatings.

It is possible that even electronic switches could be replaced by nanomechanical switches in the future. These switches would consume less energy to switch on and off than traditional transistors.

The experiments illustrated nearly ideal, frictionless movement. The graphene ribbons, measuring about 5 to 50 nm in length, could be moved using very small forces measuring between 2 to 200 pN. The experimental observations and the computer simulation revealed a high degree of uniformity. A difference between the model and reality occurs only at greater distances measuring 5 nm or more between the gold surface and the the measuring tip. This could be due to the edges of the graphene nanoribbons being saturated with hydrogen, which was not considered during the simulation experiments.

“Our results help us to better understand the manipulation of chemicals at the nano level and pave the way for creating frictionless coatings,” write the researchers.