May 4 2018

Penn State chemists have created a designer’s toolkit that allows them to construct different levels of complexity into nanoparticles using a simple, mix-and-match procedure.

“Researchers in areas as diverse as medicine, energy, and electronics often design complex nanoscale particles that are predicted to have useful functions,” said Raymond E. Schaak, DuPont Professor of Materials Chemistry at Penn State and the leader of the study team. “But making them in the laboratory is often the bottleneck. Our strategy can help to streamline this process.” A paper explaining the team’s plan and the large library of particles that they can now create appears in the May 4 issue of the Science journal.

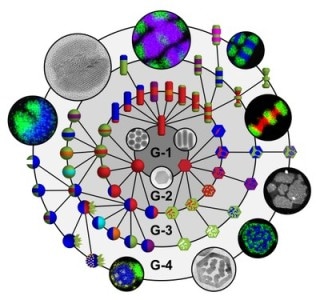

A new mix-and-match toolkit allows researchers to create a library of complex nanoparticles that could be used in medical, energy, and electronic applications. First-generation (G-1) spheres, rods, and plates transform into 47 increasingly sophisticated higher-generation (G-2, G-3, G-4) particles through sequences of chemical reactions. In the image, each color represents a distinct type of material, and electron microscope images are shown for several types of particles. (Image credit: Schaak Laboratory, Penn State)

A new mix-and-match toolkit allows researchers to create a library of complex nanoparticles that could be used in medical, energy, and electronic applications. First-generation (G-1) spheres, rods, and plates transform into 47 increasingly sophisticated higher-generation (G-2, G-3, G-4) particles through sequences of chemical reactions. In the image, each color represents a distinct type of material, and electron microscope images are shown for several types of particles. (Image credit: Schaak Laboratory, Penn State)

Researchers and engineers are becoming a lot better at designing nanoparticles to diagnose and treat cancer, to split water using sunlight, and to solve other vital problems. A number of these ‘designer’ particles have to include a variety of semiconductors, magnets, catalysts, and other materials to work, all the while adhering to strict requirements involving their shape and size.

Synthesizing these complex particles becomes a really difficult challenge, because each one of these particles requires a tour-de-force effort to prepare, and that’s not always practical. We wanted to think in a more modular way to make this process easier.

Raymond E. Schaak

The scientists start with what they refer to as first-generation particles that have nanoscale dimensions and are similar in size to viruses. These are simple, easy-to-create copper sulfide spheres, plates, and rods that act as springboards for more multifaceted derivatives. These first-generation particles define the preliminary shape and size, and after substituting some of the copper with other elements such as zinc and cadmium, they are changed to second-generation particles that at present include two materials. The new material is engraved into a portion of the original copper sulfide, forming different types of shapes or lines. These lines signify the junctions between the two materials, establishing frameworks within the particles and producing striped rods, capped rods, sandwich spheres, two-faced spheres, marbled plates, and patchy plates.

The junctions bring an additional design element to the table. Here, the materials within the particles are coupled together at the atomic level, and this can lead to additional functions because the materials can now ‘talk’ to each other. We can independently tune the outside shape and size of the particles, the materials that are inside the particles, and the ways in which they are connected.

Raymond E. Schaak

All of the second-generation particles still comprise a little copper sulfide. This ‘leftover’ copper sulfide can also be substituted, creating third-generation particles that keep the first-generation shape and size and the second-generation junctions while containing totally different materials than the original first-generation particles. Higher-generation particles are created by further mixing and matching of different methods and materials. In due course, the team easily formed a library of 47 distinct nanoparticles from the three simple first-generation rods, spheres, and plates.

Some of the particles created by the researchers are among the most complex reported until now, including particles with holes and notches in them, non-symmetrical particles, and intricately sculpted particles. “What is most exciting is how easily this works. We can sit down and draw a picture of a really complex particle that was unthinkable months ago, and then go in the lab and make it right away. This is truly a designer’s toolkit,” said Schaak.

Besides Schaak, the research team included Julie L. Fenton and Benjamin C. Steimle at Penn State. The U.S. National Science Foundation funded the research.