Jan 31 2019

The electrical resistance of graphene—a two-dimensional (2D) material—is generally distorted by water molecules, but now a group of European researchers has reported that contact resistance is not affected by humidity when graphene is incorporated with the metal of a circuit.

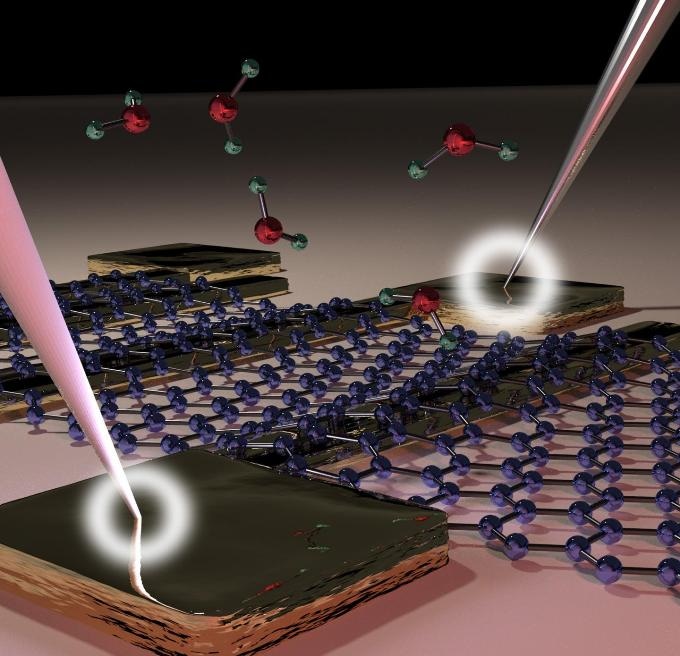

Schematic of a graphene device with a contact resistance that is not altered by the water molecules adsorbed on its surface. (Image credit: Anderson D. Smith)

Schematic of a graphene device with a contact resistance that is not altered by the water molecules adsorbed on its surface. (Image credit: Anderson D. Smith)

This latest discovery will help in developing a new generation of sensors—the interface between the real world and circuits—with a substantial reduction in cost.

Graphene is an atomically thin sheet of carbon atoms containing remarkable mechanical and conductivity properties. The various applications of this material include the development of sensors. These convert environmental parameters into electrical signals, which can then be processed and quantified using a computer.

Graphene-based sensors—–owing to their 2D structure—are highly sensitive and are anticipated to deliver excellent performance at low production cost in the next few years.

However, in order to realize this, graphene has to make efficient electrical contacts when incorporated with a traditional electronic circuit. Such perfect contacts are essential in any sensor and considerably influence its performance.

Nevertheless, a problem exists—graphene is highly sensitive to humidity, that is, to the water molecules present in the surrounding atmosphere that are adsorbed onto its surface. As a result, the electrical resistance of this carbon material is changed by the water (H2O) molecules, introducing an erroneous signal within the sensor.

Conversely, Swedish scientists have discovered that the contact resistance—the part of a material’s overall resistance caused by the imperfect contact at the interface—is unaffected by moisture when graphene adheres to the metal of electronic circuits.

This will make life easier for sensor designers, since they won't have to worry about humidity influencing the contacts, just the influence on the graphene itself.

Arne Quellmalz, PhD Student, KTH Royal Institute of Technology (Sweden).

Quellmalz is the main researcher of the study.

Reported in the journal ACS Applied Materials & Interfaces, the study was conducted experimentally utilizing graphene along with silica substrates and gold metallization in transmission line model test structures, and also computer simulations.

Graphene with conventional electronics

By combining graphene with conventional electronics, you can take advantage of both the unique properties of graphene and the low cost of conventional integrated circuits. One way of combining these two technologies is to place the graphene on top of finished electronics, rather than depositing the metal on top the graphene sheet.

Arne Quellmalz, PhD Student, KTH Royal Institute of Technology (Sweden).

Now, as part of the European CO2-DETECT project, the latest method is being used for producing the initial prototypes of graphene-based sensors. More precisely, the aim is to determine the main greenhouse gas—carbon dioxide (CO2)—using optical detection of mid-infrared light and at more reduced costs when compared to other technologies.

Apart from the KTH Royal Institute of Technology, the companies Amo GmbH from Germany and SenseAir AB from Sweden, and the Catalan Institute of Nanotechnology (ICN) from Barcelona are equal participants in the CO2-DETECT project.