Mar 22 2019

Nanowire experts at the National Institute of Standards and Technology (NIST) have developed ultraviolet light-emitting diodes (LEDs) with a unique type of shell that generates five times higher light intensity when compared to similar LEDs based on a simpler shell design.

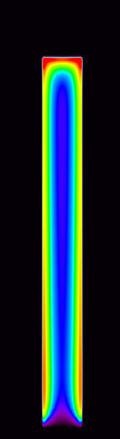

Model of nanowire-based light-emitting diode showing that adding a bit of aluminum to the shell layer (black) directs all recombination of electrons and holes (spaces for electrons) into the nanowire core (multicolored region), producing intense light. (Image credit: NIST)

Model of nanowire-based light-emitting diode showing that adding a bit of aluminum to the shell layer (black) directs all recombination of electrons and holes (spaces for electrons) into the nanowire core (multicolored region), producing intense light. (Image credit: NIST)

Ultraviolet LEDs are employed in an increasing number of applications, for example, water purification, polymer curing, and medical disinfection. Micro-LEDs are also useful for visual displays. NIST employees are performing experiments with nanowire-based LEDs for scanning-probe tips designed for electronics and biology applications.

The innovative, brighter LEDs are a result of NIST’s proficiency in producing high-quality gallium nitride (GaN) nanowires. Recently, scientists have been testing nanowire cores composed of silicon-doped GaN, which has additional electrons, enclosed by shells composed of magnesium-doped GaN, with an excess of “holes” for missing electrons. Upon combining an electron with a hole, energy is emitted in the form of light, in a process called electroluminescence.

The NIST team previously established GaN LEDs that generated light when electrons injected into the shell layer recombined with holes. A small bit of aluminum is added to the shell layer in the new LEDs, which decreases losses from light reabsorption and electron overflow.

As reported in the journal Nanotechnology, the brighter LEDs are made from nanowires with what is called a “p-i-n” structure, which is a tri-layer design that injects electrons and holes into the nanowire. The incorporation of aluminum into the shell helps limit electrons to the nanowire core, thus increasing the electroluminescence by five times.

The role of the aluminum is to introduce an asymmetry in the electrical current that prevents electrons from flowing into the shell layer, which would reduce efficiency, and instead confines electrons and holes to the nanowire core.

Matt Brubaker, Study First Author, NIST.

The length of the nanowire test structures was around 440 nm and their shell thickness was around 40 nm. The final LEDs, together with the shells, were nearly 10 times bigger. Scientists identified that the amount of aluminum added to the fabricated structures is dependent on the diameter of the nanowire.

Kris Bertness, who heads the team, stated that at least two companies are producing micro-LEDs based on nanowires, and NIST has a Cooperative Research and Development Agreement with one of the companies to create dopant and structural characterization approaches. The scientists have had preliminary discussions with scanning-probe companies about using NIST LEDs in their probe tips, and NIST intends to exhibit prototype LED tools shortly.

The NIST group owns U.S. Patent 8,484,756 on an instrument that integrates microwave scanning probe microscopy with an LED for nondestructive, contactless testing of material quality for vital semiconductor nanostructures like transistor channels and individual grains in solar cells. The probe could also be employed for biological research on cell structure and protein unfolding.