May 23 2019

A research group at Osaka University has discovered a new approach for developing high-precision sensing devices that react to the presence of hydrogen gas.

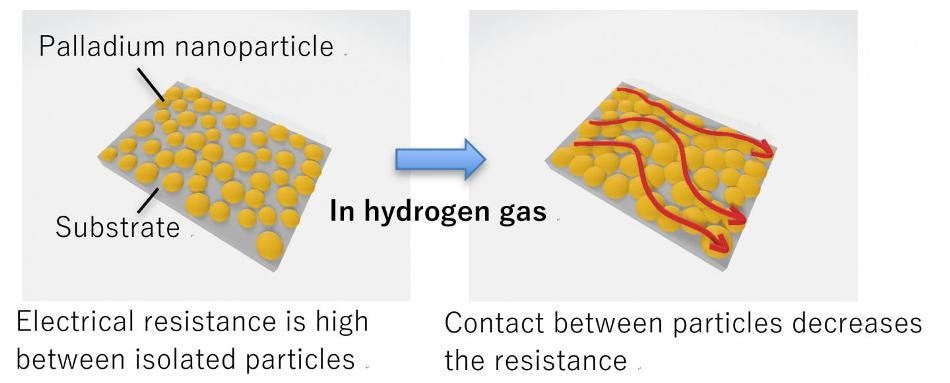

Schematic of hydrogen sensing using palladium nanoparticles. Without hydrogen present, the metallic palladium nanoparticles (orange dots) act as isolated islands, and electric current cannot flow easily across the device. In contrast, when the device is exposed to even a small amount of hydrogen, the hydrogen atoms can bridge the gaps between islands, creating a connected network that allows a large current to pass through (red lines). (Image credit: Osaka University)

Schematic of hydrogen sensing using palladium nanoparticles. Without hydrogen present, the metallic palladium nanoparticles (orange dots) act as isolated islands, and electric current cannot flow easily across the device. In contrast, when the device is exposed to even a small amount of hydrogen, the hydrogen atoms can bridge the gaps between islands, creating a connected network that allows a large current to pass through (red lines). (Image credit: Osaka University)

By cautiously controlling the piling up of metallic nanoparticles on a silicon surface, the scientists were able to develop a sensor that can detect low levels of hydrogen based on variations in electrical current. This study may have significant advantages as part of a switch to hydrogen-based fuels, which could enable the imminent zero-emission cars and help combat anthropogenic climate change.

To create a hydrogen sensor, the scientists deposited metallic palladium on a silicon substrate. The deposited palladium develops nanoparticles on the substrate, and they function as tiny islands that are exceptional conductors of electricity; however, as they do not form a connected network, the current across the device is extremely less.

However, when there are hydrogen atoms, they are absorbed into the palladium nanoparticles, increasing volume of the nanoparticles, and subsequently connect the spaces between the islands. Ultimately, a fully connected path is created, and electrons can flow with much less resistance. Thus, even a slight variation in hydrogen concentration can result in a huge increase in current; therefore, the devices can be made extremely sensitive.

An important problem which the Osaka scientists had to solve was accurately controlling the spaces between islands to deposit in the first place. In case the deposition time was very short, gaps between the nanoparticles would be too broad and it would not be possible to bridge them even in the presence of hydrogen.

On the contrary, if the deposition time was too long, the nanoparticles would develop a connected network by themselves, even before the application of hydrogen. To improve the response of the sensor, the group of scientists created a new approach for monitoring and controlling the deposition of palladium known as piezoelectric resonance.

Piezoelectric materials, such as a quartz crystal in a wristwatch, can vibrate at a very specific frequency in response to an applied voltage.

Dr Hirotsugu Ogi, Study Senior Author, Osaka University

In this method, a piece of piezoelectric lithium niobate was set to vibrate beneath the sample during the metallic nanoparticle deposition. The oscillating piezoelectric formed an electric field around the sample, which in turn produced a current in the device that was dependent on the connectivity of the palladium network.

Consequently, the attenuation of the oscillation varies based on the connectivity. Thus, by listening to the sound (measuring the attenuation) of the piezoelectric material, the connectivity can be monitored.

By optimizing the deposition time using the piezoelectric resonance method, the resulting hydrogen sensors were 12 times more sensitive than. These devices may represent a step towards a cleaner energy future involving hydrogen.

Dr Nobutomo Nakamura, Study First Author, Osaka University

The research is reported in Applied Physics Letters as “Precise control of hydrogen response of semicontinuous palladium film using piezoelectric resonance method.”