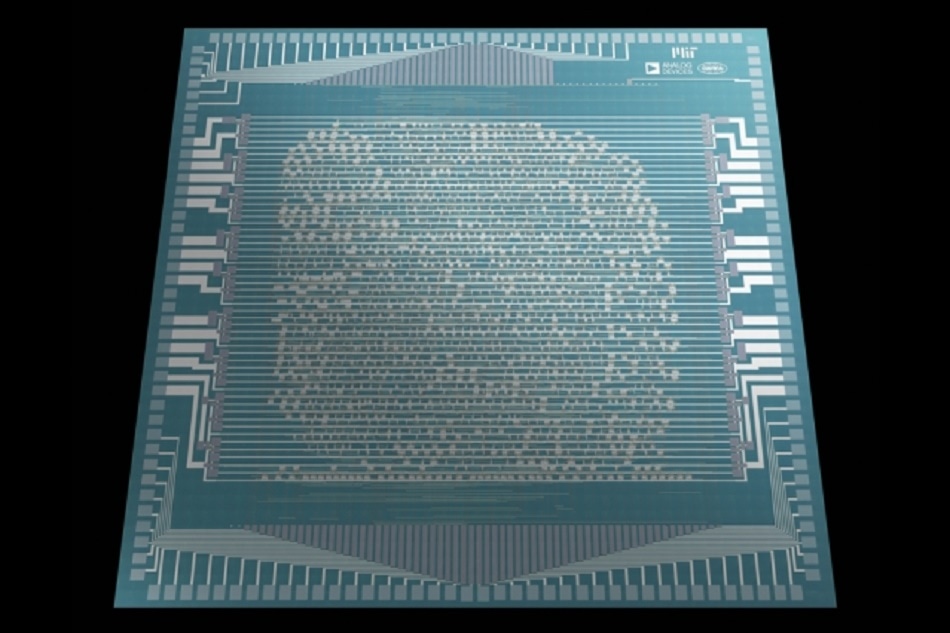

MIT researchers have constructed a state-of-the-art microprocessor from carbon nanotube transistors which as well as being faster in their capabilities are considered to be a greener alternative than the current dominant silicon-based chips.

Image Credit: MIT

MIT researchers have constructed a state-of-the-art microprocessor from carbon nanotube transistors which as well as being faster in their capabilities are considered to be a greener alternative than the current dominant silicon-based chips.

Image Credit: MIT

It is thought that in the world of advanced computing and the progression towards creating next generation computers the next step required will be making significant headway in nanotechnology.

Now, MIT researchers have constructed a state-of-the-art microprocessor from carbon nanotube transistors which as well as being faster in their capabilities are considered to be a greener alternative than the current dominant silicon-based chips.

The new microprocessor, as described in the journal Nature, can be made by harnessing conventional silicon-chip fabrication methods. This means that making carbon nanotube microprocessors could both more practical and accessible going forward. The team from MIT state in their paper that, “this work experimentally validates a promising path towards practical beyond-silicon electronic systems.”

Previously, industry has wielded the capability to continually load more and more transistors onto microchips – in accordance with Moore’s Law - yet, experts now believe the end could be in sight for silicon-based chips. This is seen as a major paradigm shift due to the possibility that silicon transistor scaling could soon cease to provide the same energy-efficient benefits the industry is used to as it becomes increasingly difficult to continually shrink the transistors.

Thus, the goal of producing carbon nanotube field effect transistors (CNFET) has become a priority for the development of designing and building the next-generation of computers. The latest research suggests that CNFETs have the qualities required to increase the energy efficiency up to 10x that of silicon as well as providing far greater processing speeds.

This is by far the most advanced chip made from any emerging nanotechnology that is promising for high-performance and energy-efficient computing.

Max M. Shulaker, co-author of the paper, Emanuel E Landsman Career Development Assistant Professor of Electrical Engineering and Computer Science (EECS) and a member of the Microsystems Technology Laboratories

However, when typically fabricated at requisite scale, carbon nanotube transistors can often present defects which makes implementation into industrial methods far from practical. So, the team from MIT came up with new techniques to profoundly reduce defects whilst maintaining full functional control in fabricating CNFETs, utilizing the processes synonymous with silicon fabrication.

The architecture of the microprocessor is based on the RISC-V open-source chip that comes equipped with a set of instructions and tasks that a microprocessor can execute. The MIT microprocessor was able to perform the full set of instructions with great precision. It also carried out the classic “Hello, World!” program with a twist, printing out, “Hello, World! I am RV16XNano, made from CNTs.”

This progress marks the start of a remarkable breakthrough in post-silicon electronic and nanotechnologies. “There are limits to silicon. If we want to continue to have gains in computing, carbon nanotubes represent one of the most promising ways to overcome those limits. [The paper] completely re-invents how we build chips with carbon nanotubes,” stated Shulaker.

The microprocessor takes its cue from an iteration designed by Shulaker and other researchers six years ago that had only 178 CNFETs and ran on a single bit of data. Subsequently, Shulaker and his MIT colleagues have had to overcome three challenges in the production of the devices: manufacturing defects, material defects, and functional issues. Gage Hills, first author of the study and postdoc at Department of Electrical Engineering and Computer Science, MIT, did the bulk of the microprocessor design, while Christian Lau, co-author, handled most of the manufacturing.

Over the years, the defects of the carbon nanotubes have been a “bane of the field,” Shulaker says. Typically, CNFETs require semiconducting properties to switch their conductivity on and off, corresponding to the bits 1 and 0. Yet, a small portion of carbon nanotubes will be metallic, often slowing or stopping the transistor from switching. To stand up to those failures, circuits with advanced capability will need carbon nanotubes with about 99.999999 percent purity, which is nearly impossible to produce today.

The team developed a technique called DREAM (designing resiliency against metallic CNTs), which places metallic CNFETs so that they won’t disrupt computing. In doing so, the stringent purity requirement was relaxed by around four orders of magnitude – or 10,000 times – thus, only carbon nanotubes at about 99.99 percent purity are required, which is currently possible. “The ‘DREAM’ pun is very much intended, because it’s the dream solution,” Shulaker says. “This allows us to buy carbon nanotubes off the shelf, drop them onto a wafer, and just build our circuit like normal, without doing anything else special.”

Particular metals such as platinum or titanium are affixed to each transistor which allows them to fix that transistor as P or N. This is followed by coating the CNFETs in an oxide compound through atomic-layer deposition. This part of the process allows for the tuning of the transistors’ characteristics for specific applications. For example, servers often need transistors that can operate at extremely high speeds, but they also consume a lot of energy and power. Medical implants, on the other hand, may use slower, low-power transistors.

The end game for the team is to get the chips out into the real world. Therefore, through a program by Defense Advanced Research Projects Agency which supported the research, the researchers have begun implementing their manufacturing techniques into a silicon chip foundry. Whilst an exact timescale cannot be given as to when we will see the next generation of computers or chips made up of carbon nanotubes, Shulaker believes it could be within five years. “We think it’s no longer a question of if, but when,” he says.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.