Feb 12 2020

Materials science researchers from McCormick School of Engineering of Northwestern University have developed a technique to observe the atoms’ dynamic movement in atomically thin two-dimensional (2D) materials.

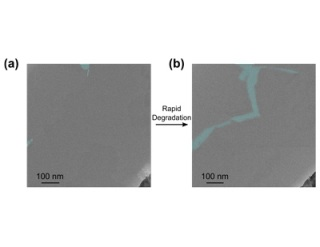

An image of void coalescence. On left, a low-magnification TEM of MoS2 grain boundary region before biasing. On the right, the same region after an electrical bias is applied. As is apparent, neighboring voids (blue) appear to coalesce to form porous chains. Image Credit: Northwestern University.

An image of void coalescence. On left, a low-magnification TEM of MoS2 grain boundary region before biasing. On the right, the same region after an electrical bias is applied. As is apparent, neighboring voids (blue) appear to coalesce to form porous chains. Image Credit: Northwestern University.

The new imaging method, which demonstrates the fundamental cause responsible for the performance failure of an extensively-used 2D material, can help scientists to create more reliable and stable materials for upcoming flexible electronic devices and wearables.

These 2D materials—namely borophene and graphene—are a group of single-layer, crystalline materials that have great potential as semiconductors in next-generation flexible and ultra-thin electronics.

However, the thin nature of these materials makes them extremely susceptible to external settings, and, as a result, they have struggled to show long-term reliability and stability when used in electronic devices.

Atomically thin 2D materials offer the potential to dramatically scale down electronic devices, making them an attractive option to power future wearable and flexible electronics,

Vinayak Dravid, Abraham Harris Professor, Department of Materials Science and Engineering, McCormick School of Engineering, Northwestern University

The study, titled “Direct Visualization of Electric Field-induced Structural Dynamics in Monolayer Transition Metal Dichalcogenides,” was published in the ACS Nano journal on February 11th, 2020.

The study’s corresponding author is Vinayak Dravid. The research also involved Chris Wolverton, the Jerome B. Cohen Professor of Materials Science and Engineering,

“Unfortunately, electronic devices now operate as a kind of ‘black box.’ Although device metrics can be measured, the motion of single atoms within the materials responsible for these properties is unknown, which greatly limits efforts to improve performance,” Dravid stated.

Dravid serves as a director of the Northwestern University Atomic and Nanoscale Characterization (NUANCE) Center. The study provides a means to move beyond that restriction, with a new insight into the structural dynamics involved in 2D materials receiving electrical current.

Based on an earlier study where the scientists utilized a nanoscale imaging method to visualize heat-induced failure in 2D materials, the team employed a high-resolution, atomic-scale imaging technique known as electron microscopy to view the motion of atoms in molybdenum disulfide (MoS2). MoS2 is an extensively researched material that was initially utilized as a dry lubricant in friction materials and greases; this dry lubricant was recently in the limelight for its optical and electronic properties.

Upon applying an electric current to the material, the scientists observed that the highly mobile sulfur atoms in this material always move to empty areas within the crystalline material, a phenomenon which the team called “atomic dance.”

That movement of the atoms caused the grain boundaries of MoS2 to separate and form narrow channels for the electrical current to pass through. Grain boundaries are natural defects produced in the space, where a pair of crystallites inside the material meet.

As these grain boundaries separate, you are left with only a couple of narrow channels, causing the density of the electrical current through these channels to increase. This leads to higher power densities and higher temperatures in those regions, which ultimately leads to failure in the material.

Akshay Murthy, Study Lead Author and PhD Student, Department of Materials Science and Engineering, Northwestern University

Murthy is part of Dravid’s team.

“It’s powerful to be able to see exactly what’s happening on this scale,” continued Murthy. “Using traditional techniques, we could apply an electric field to a sample and see changes in the material, but we couldn’t see what was causing those changes. If you don’t know the cause, it’s difficult to eliminate failure mechanisms or prevent the behavior going forward.”

With this latest method to analyze 2D materials at the atomic level, the researchers believe that investigators can apply this imaging technique to produce materials that are less likely to fail in electronic devices.

For instance, in memory devices, scientists can visualize how regions where data is stored, emerge upon applying an electric current and adapt how those kinds of materials are developed for more improved performance.

The method may even help to enhance a range of other technologies, such as light-emitting diodes (LEDs) in consumer electronics, transistors in bioelectronics, and photovoltaic cells integrated with solar panels.

We believe the methodology we have developed to monitor how 2D materials behave under these conditions will help researchers overcome ongoing challenges related to device stability. This advance brings us one step closer to moving these technologies from the lab to the marketplace.

Akshay Murthy, Study Lead Author and PhD Student, Department of Materials Science and Engineering, Northwestern University