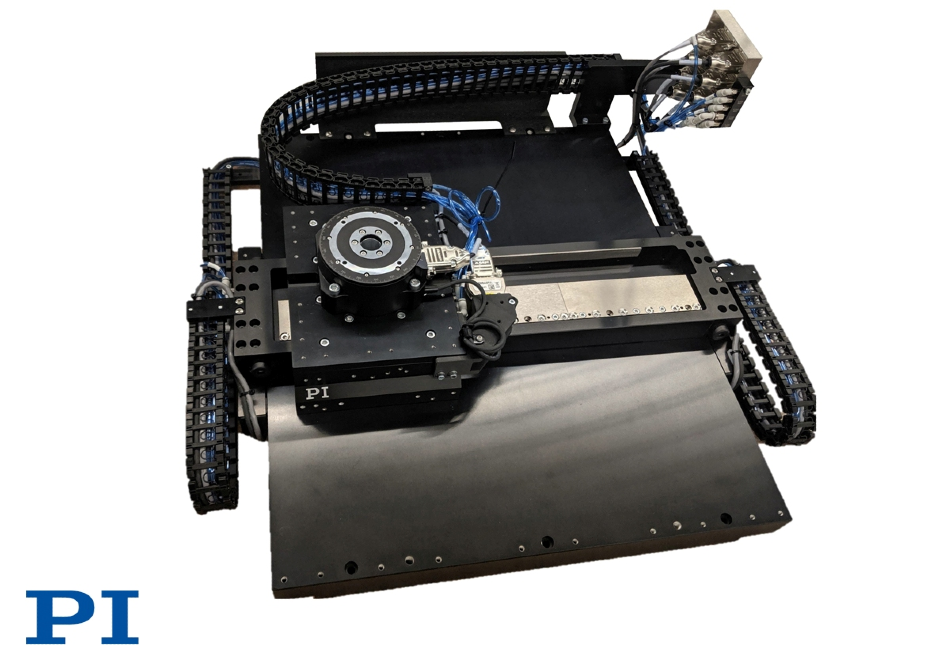

Worldwide nanopositioning solutions leader PI adds to its compact A-311 line of low-profile planar XY air bearing stages. PI’s US-based air bearing R&D and manufacturing teams have created 2 new versions with travel ranges of 200x200 mm and 300x300 mm. Planar scanning stages are ideal for semiconductor inspection, laser marking, optical metrology, and other precision motion applications.

Compact, Lightweight, Precise

The compact A-311 air bearing planar series uses a hardcoat aluminum base and two motors, reducing size, weight and cost compared to traditional granite based planar XY stages. Excellent motion fidelity is achieved, for example 1 µm straightness over 300 mm (and 10 nm per 10 mm) and 10µrad orthogonality over 300mm. Integrated absolute measuring linear encoders provide:

- 1 nm resolution

- 0.1 µm bidirectional repeatability

- 0.2 µm accuracy

The stages are controlled by a high performance, EtherCat® based motion controller with advanced features such as ServoBoost® and NanoPWM® for higher resolution and adaptability to a wider load range.

Why Use Planar Air Bearings in Precision Positioning Equipment?

Air bearing positioners float on air to provide completely frictionless motion, resulting in negligible hysteresis or reversal error, excellent velocity stability, and zero-wear of mechanical components. Due to the surface averaging effect, straightness and flatness, along with pitch/yaw/roll, are significantly better than with conventional mechanical bearings. Requiring no maintenance or lubrication, air bearings are ideal for use in cleanrooms.

Linear Motors and Encoders for High Speed and Acceleration

Smooth motion with no cogging is provided by ironless linear motors; position information down to 1nm resolution comes from the integrated absolute linear encoders. Features and advantages include:

- Velocities up to 2 m/sec

- Acceleration to 2.75g

- Load capacity is increased to 147N (~30lb)

- Cleanroom compatibility

Customization/OEM: Additional Rotation Stages or Tip-Tilt

The planar XY stages can be combined with air bearing rotary stages for 3-axis, XY-Theta-Z motion applications. PI’s rotary air bearing stages are available with diameters from 50 mm to 300 mm and provide excellent motion properties with eccentricity down to 75 nm and wobble down to 1µrad. Low profile, Z/tip-tilt options are also available.

Standard and Custom

PI has in-house engineered solutions with over 4 decades of experience working with customers to provide products that meet application demands, and can quickly modify existing product designs or provide a fully customized OEM part to fit the exact requirements of the application.