Oct 30 2020

An easy way to form nanoscale diamonds would be to combine two layers of graphene but, at times, thicker can turn out to be better.

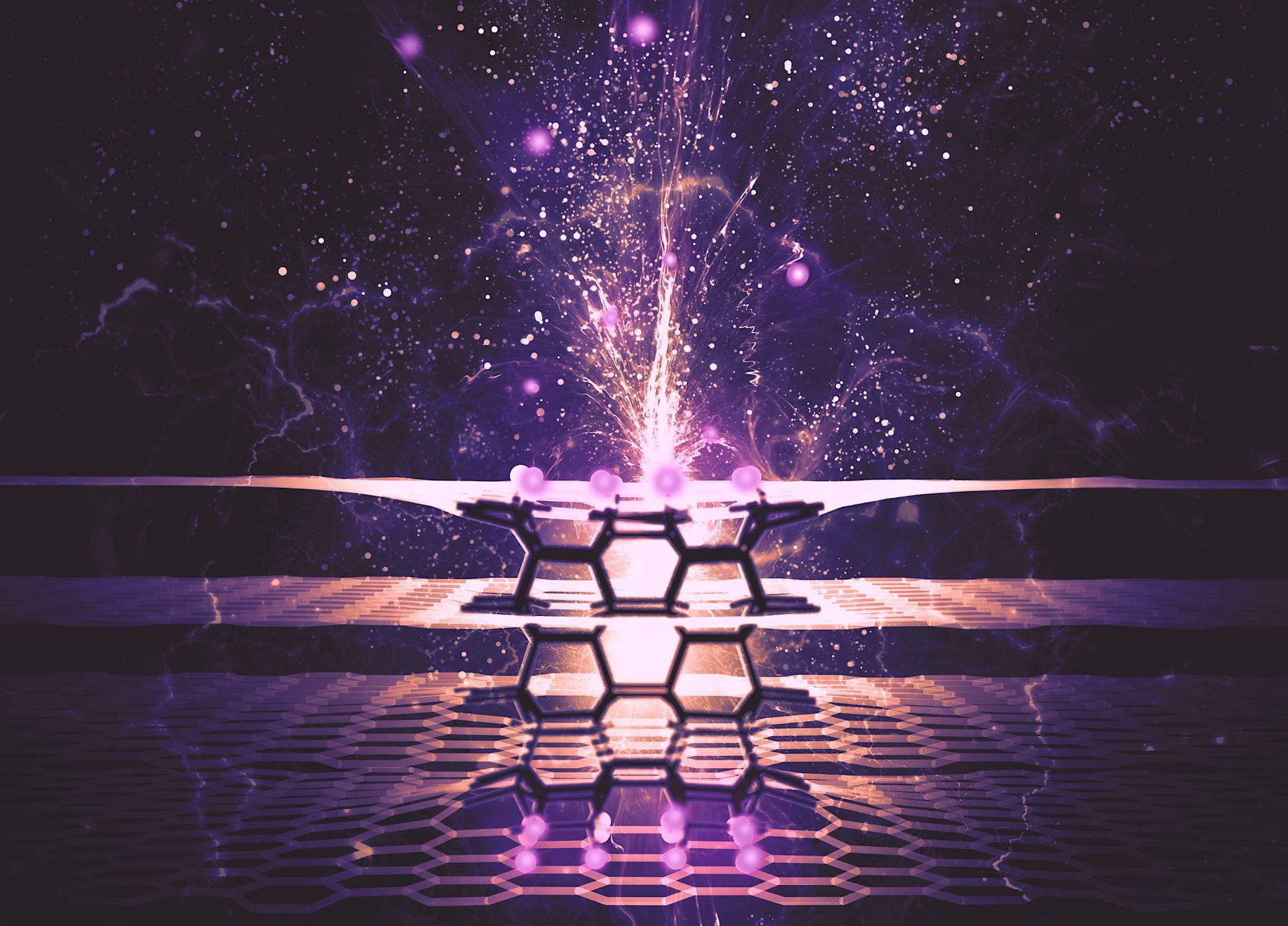

Rice University researchers have expanded their theory on converting graphene into 2D diamond, or diamane. They have determined that a pinpoint of pressure can trigger connections between layers of graphene, rearranging the lattice into a cubic diamond. Image Credit: Illustration by Pavel Sorokin.

Rice University researchers have expanded their theory on converting graphene into 2D diamond, or diamane. They have determined that a pinpoint of pressure can trigger connections between layers of graphene, rearranging the lattice into a cubic diamond. Image Credit: Illustration by Pavel Sorokin.

Although it may take just a small amount of heat to obtain a cubic lattice of diamane from a treated bilayer of the ultrathin material, few-layer graphene can also be converted by applying slight pressure in just the precise place.

Now, according to scientists from Rice University, the otherwise chemically driven procedure is theoretically viable. Rice University has published its most recent thoughts on producing high-quality diamane—the two-dimensional (2D) form of diamond—in the Small journal.

Headed by materials theorist Boris Yakobson and his collaborators from the George R. Brown School of Engineering at Rice University, the researchers have suggested that a bit of pressure applied to few-layer graphene—the atom-thin form of carbon familiar for its exceptional strength—can nucleate a surface chemical reaction with fluorine or hydrogen.

And from there, the diamond-like lattice should spread across the material as atoms of fluorine or hydrogen alight on the bottom and top and covalently attach to the surfaces, triggering carbon-carbon connections between the layers.

Yakobson stated that the pressure applied to that place—down to a few nanometers—is completely unnecessary in the case of a bilayer but is nevertheless required and should be increasingly stronger for thicker films.

Large-scale production of synthetic diamonds from bulk graphite needs 725,000 pounds per square inch or around 10 to 15 gigapascals of pressure.

Only at the nanoscale—in this case, at nanometer thickness—does it becomes possible for the surface chemistry alone to change the thermodynamics of the crystal, shifting the phase-change point from very high pressure to practically no pressure.

Boris Yakobson, Materials Theorist, George R. Brown School of Engineering, Rice University

For electronics, single-crystal diamond film is largely preferred. The material can possibly be utilized as a heat transducer or as a hardened insulator for cooling nanoelectronics. It may even be doped to act as an element in optical applications, or as a wide-bandgap semiconductor in transistors.

In 2014, Yakobson and his collaborators had designed a phase diagram to demonstrate how diamane can be thermodynamically viable. While there is still no easy way to produce the diamane, the latest study adds a crucial element that was missing in the previous study—a means to address the energetic obstacle to nucleation that maintains the reaction.

So far only bilayer graphene has been reproducibly converted into diamane, but through sheer chemistry. Combining it with a pinch of local pressure and the mechanochemistry it triggers seems like a promising path to be tried.

Boris Yakobson, Materials Theorist, George R. Brown School of Engineering, Rice University

“In thicker films, the barrier rises quickly with the number of layers,” added Pavel Sorokin, the study’s co-author and a former postdoctoral associate from Rice University. “External pressure can reduce this barrier, but chemistry and pressure must play together to deliver a 2D diamond.”

Sergey Erohin, a visiting researcher from Rice University and a graduate student at the National University of Science and Technology in Moscow, is the lead author of the study. Qiyuan Ruan, a graduate student from Rice University, is the co-author of the study.

Sorokin heads a laboratory at the Technological Institute for Superhard and Novel Carbon Materials based in Moscow. Yakobson is the Karl F. Hasselmann Professor of Materials Science and NanoEngineering and also a professor of chemistry from Rice University.

The study was funded by the Rice-Army Research Initiative, the Office of Naval Research, and the Ministry of Education and Science of the Russian Federation.

Journal Reference:

Erohin, S. V., et al. (2020) Nano-Thermodynamics of Chemically Induced Graphene–Diamond Transformation. Small. doi.org/10.1002/smll.202004782.