Dec 10 2020

Despite the fact that water covers a major part of the planet Earth, just a fraction of it is clean enough for human use.

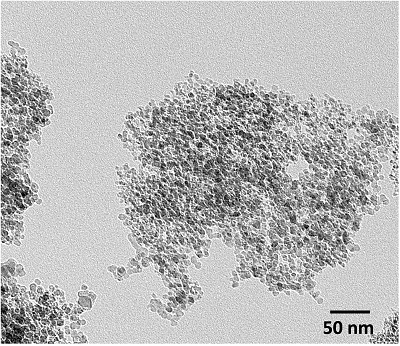

Microscopic nanodiamonds clump together when placed in water (shown above), but dissociate when in ethyl acetate to clean hot wastewater. Image Credit: Adapted from ACS Applied Materials & Interfaces 2020.

Microscopic nanodiamonds clump together when placed in water (shown above), but dissociate when in ethyl acetate to clean hot wastewater. Image Credit: Adapted from ACS Applied Materials & Interfaces 2020.

Thus, it is essential to recycle this resource as far as possible. Existing methods to purify water cannot properly deal with the very hot wastewater produced by a few industries.

However, scientists have now integrated amine-enhanced nanodiamond particles into membranes to overcome this difficulty. The findings have been reported in ACS Applied Materials & Interfaces.

Certain oil recovery techniques and other industrial processes lead to the synthesis of hot wastewater, which needs energy-intensive cooling before being purified via conventional reverse osmosis membranes.

Following purification, the water must then be heated before it is re-used. At such high temperatures, conventional reverse osmosis membranes filter gradually, permitting more salts, solids and other contaminants to pass through.

Scientists have combined extremely tiny nanodiamonds—carbon spheres generated by explosions in small, closed containers in the lack of oxygen—into these membranes in earlier studies. The membranes can quickly and effectively filter huge volumes of water and can safeguard against fouling, but they were not tested with very hot samples.

To improve the membranes for use with hot wastewater, Khorshidi, Sadrzadeh and collaborators wanted to alter the nanodiamond spheres and combine them in a new way.

The researchers fixed amines to nanodiamonds and bathed them in an ethyl acetate solution to avoid clumping of the spheres. A monomer was then added for reaction with the amines to make chemical links to the conventional membrane base.

Synergistic impacts of the amine links and the ethyl acetate treatment led to thicker, more temperature-stable membranes, enabling enhancements in their performance.

The researchers increased the amount of amine-enhanced nanodiamonds in the membrane and thus achieved higher filtration rates with the elimination of a higher proportion of impurities, even after 9 hours at 167 °F, in comparison with membranes without nanodiamonds.

According to the researchers, the new technique helped produce membranes that could more efficiently treat wastewater at higher temperatures.

This study was financially supported by Canada’s Oil Sands Innovation Alliance and The Natural Sciences and Engineering Research Council of Canada (NSERC).

Journal Reference

Karami, P., et al. (2020) Nanodiamond-Enabled Thin-Film Nanocomposite Polyamide Membranes for High-Temperature Water Treatment. ACS Applied Materials & Interfaces. doi.org/10.1021/acsami.0c15194.