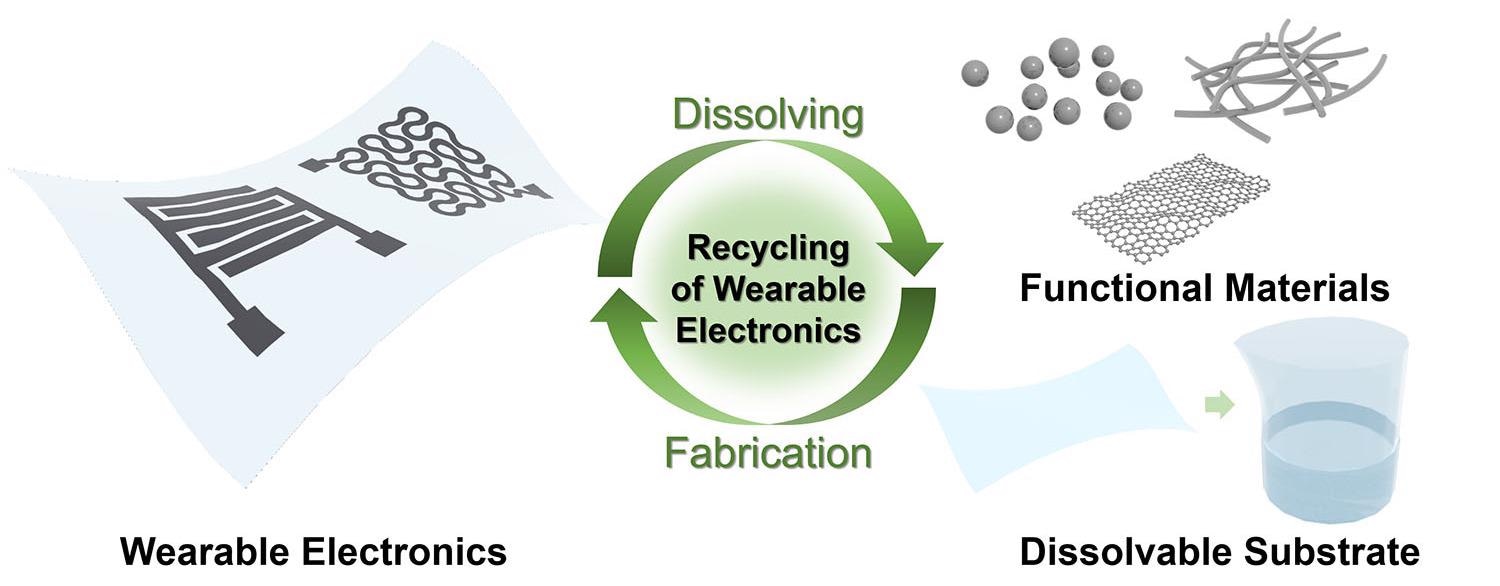

A new economical technique to retrieve nanowires from electronic devices that have attained the end stage of their utility, which can then be used in new devices, could be a step forward in producing more sustainable electronics.

Image Credit: North Carolina State University.

The new technique was developed and demonstrated by scientists from North Carolina State University (NC State).

“There is a lot of interest in recycling electronic materials because we want to both reduce electronic waste and maximize the use we get out of rare or costly materials. We’ve demonstrated an approach that allows us to recycle nanowires, and that we think could be extended to other nanomaterials—including nanomaterials containing noble and rare-earth elements,” stated Yuxuan Liu, first author of the study and a PhD student at NC State.

Our recycling technique differs from conventional recycling. When you think about recycling a glass bottle, it is completely melted down before being used to create another glass object. In our approach, a silver nanowire network is separated from the rest of the materials in a device.

Yong Zhu, Study Corresponding Author and the Andrew A. Adams Distinguished Professor of Mechanical and Aerospace Engineering, North Carolina State University

“That network is then disassembled into a collection of separate silver nanowires in solution. Those nanowires can then be used to create a new network and incorporated into a new sensor or other devices,” added Zhu.

The complete life cycle of a device is considered by the new recycling method. The initial step is to develop devices with polymers that are soluble in solvents that do not dissolve nanowires.

As soon as a device is utilized, the polymer matrix with the silver nanowires is dissolved, transcending the nanowire network. Then, the network is placed in a separate solvent and treated with ultrasound. This process makes the nanowires to get dispersed, thereby pulling them apart from the network.

In a proof-of-principle illustration, a wearable health sensor patch was designed by scientists that could help track the hydration and temperature of a patient. The sensor was made up of silver nanowire networks fixed in a polymer material. The sensors were tested to guarantee that they were completely functional. Generally, a sensor patch is thrown away after being used.

However, for their demo, the team dissolved the polymer in water, eliminated the nanowire network, cut it down into a collection of separate nanowires and further utilized those nanowires to design a brand-new wearable sensor.

The researchers concluded that the nanowires could be recycled four times without causing any harm to the performance of the sensor, while a slight degradation in the properties of the nanowire network following each “life cycle” was observed.

On the completion of four life cycles, the performance of the nanowire network can be enhanced by adding new silver nanowires into the mix.

Using our approach, you get far more use from the nanowires. And even after the nanowires have broken down many times, to the point where they can’t be reused, we can still use them as feedstock for conventional recycling. It’s a tremendous reduction in waste.

Yong Zhu, Study Corresponding Author and the Andrew A. Adams Distinguished Professor of Mechanical and Aerospace Engineering, North Carolina State University

One major factor involved in the recycling process is determining a solvent featuring a low surface tension for use in splitting the nanowire network.

“Low surface tension is important because it makes it easier for the solvent to diffuse into the narrow junctions between nanowires in the network, facilitating the disassembling of the network,” stated Liu.

Moreover, the researchers discovered that it is necessary to determine the correct balance of time when splitting the nanowire networks using ultrasound. If the ultrasound is being applied for a very long time, the nanowires could break. If the ultrasound is not employed long enough, clumps of nanowires can form.

The approach we’ve demonstrated here could be used to recycle other nanomaterials – such as nanoparticles, carbon nanotubes, other types of nanowires, and two-dimensional materials – as long as they are used in the form of a network.

Yong Zhu, Study Corresponding Author and the Andrew A. Adams Distinguished Professor of Mechanical and Aerospace Engineering, North Carolina State University

The study was co-authored by Hongyu Wang, a PhD student from the NC State. The work was performed with financial support from the National Science Foundation, under grant 1728370.

Journal Reference:

Liu, Y., et al. (2021) Recycling of Nanowire Percolation Network for Sustainable Soft Electronics. Advanced Electronic Materials. doi.org/10.1002/aelm.202100588.