Reviewed by Alex SmithSep 3 2021

A group of researchers from VTT Technical Research Centre of Finland (VTT) has developed a sustainable multiphase nanocomposite that imitates the peachick mantis shrimp club and utilized it to make new dental implant crowns in the laboratory.

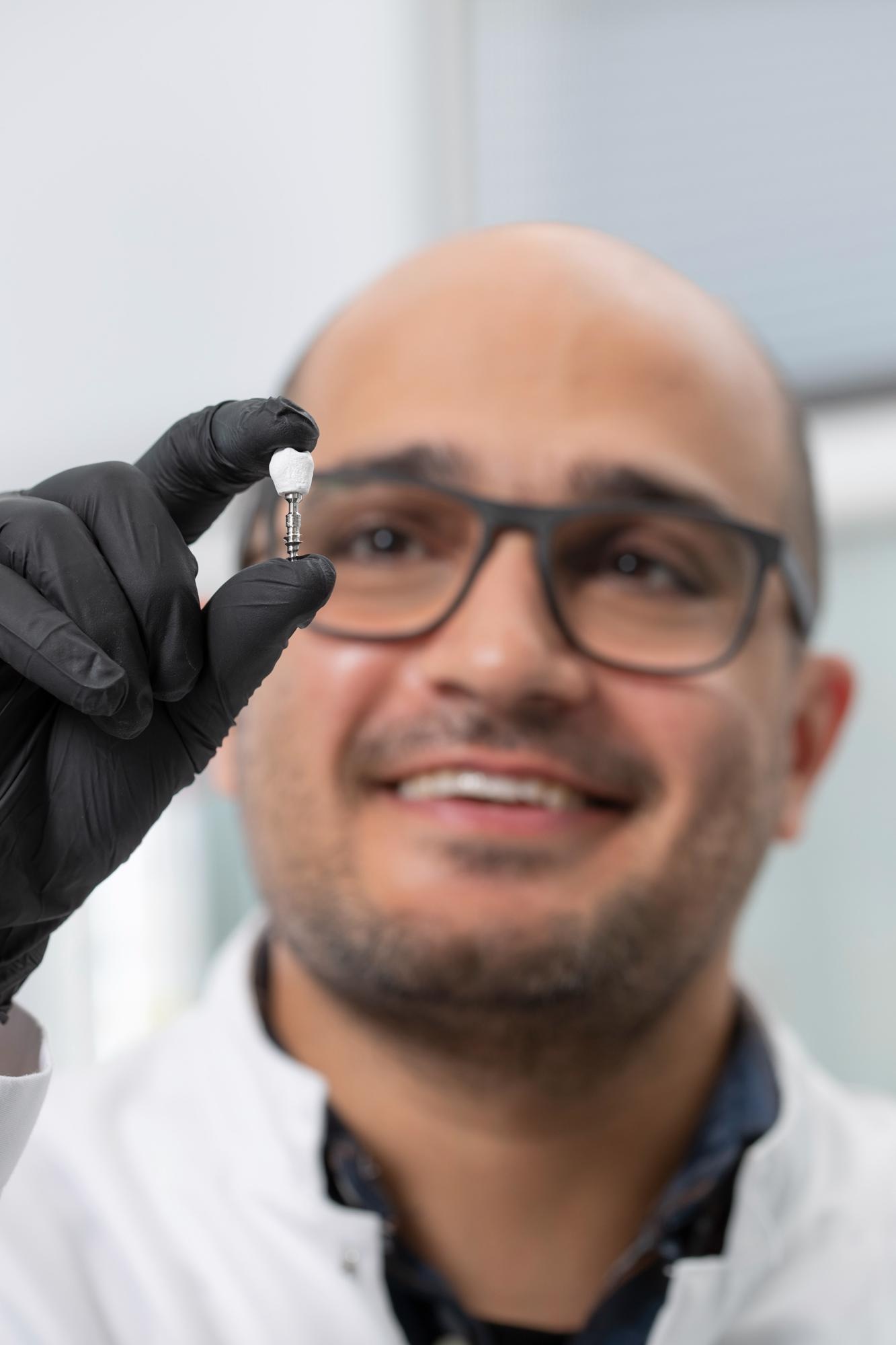

Research Scientist Pezhman Mohammadi presenting VTT’s nanocellulose-based dental implant crown. Image Credit: VTT Technical Research Centre of Finland.

Research Scientist Pezhman Mohammadi presenting VTT’s nanocellulose-based dental implant crown. Image Credit: VTT Technical Research Centre of Finland.

This was done in collaboration with scientists from Nanyang Technological University.

The new bio-inspired material is a blend of birch-cellulose and a class of genetically engineered proteins. The final result is a tougher, stronger material that is considerably lighter compared to man-made technical ceramics.

It exhibits a high potential of being used as a next-generation material in impact-resistant implants, body armors, sports equipment, electronics, exoskeletons for aircraft or surface coatings for windshields, for instance.

Nature offers exceptional insights into design strategies developed by living organisms to build strong materials. In this instance, the researchers were capable of making a new impact-resistant material motivated by the dactyl club of the mantis shrimp.

The new material can be used for applications where it is essential to endure repeated high strain-rate impacts while retaining structural integrity. The study findings were published in the Advanced Materials journal on September 1st, 2021.

Mimicking Mantis Shrimp’s Club

VTT researchers successfully developed and created a mineralized biocomposite with high stiffness, strength and fracture toughness that matches the architectural design of the mantis shrimp’s dactyl club.

These mesmerizing shrimps are one of nature’s deadliest killing machines. In relation to their small size, they pack the strongest punch in the animal kingdom. They smash their prey by throwing a pair of hammer-like raptorial appendages with a tremendous speed and force greater than rifle bullets during close-range hunting.

Dr. Pezhman Mohammadi, Study Corresponding Author and Research Scientist, VTT Technical Research Centre of Finland

“The mantis shrimp’s primary sources of food are hard-shell marine organisms, such as mollusks. To get to the soft, nutritious part they obliterate straight through these highly mineralized exoskeletons,” added Dr. Mohammadi.

Previous studies have demonstrated that the club is a multiphase hierarchically ordered nanocomposite exhibiting graded mechanical properties.

The club has a soft interior layer providing energy dissipation and a stiff, hard, and impact-resistant exterior layer. Together, the layers enhance the overall damage tolerance of the club. Both layers have similar building blocks, but in different relative content, polymorphic form, and organization. The main building block is helicoidally ordered chitin nano-fibrils that are glued together by a protein-rich matrix.

Dr. Pezhman Mohammadi, Study Corresponding Author and Research Scientist, VTT Technical Research Centre of Finland

Combining Cellulose Nanocrystals and Proteins

The research team reproduced this structure by making use of similar building blocks and processing conditions. They gathered new composite comprising cellulose nanocrystals and two kinds of genetically engineered proteins.

One of the proteins was engineered to raise the material’s interfacial strength and the other one for mediating nucleation and growth of hydroxyapatite crystals. This new composite was refined into complex shapes by making it into a dental implant crown, including periodic patterns of micro-reinforcement orientation and a bilayer architecture like human teeth.

More analyses could help engineer the proteins to offer new characteristics to the material. For applications in the future, the material’s scalability and processing conditions require additional development.

The research group included experts in protein engineering, synthetic biology, soft-matter physics and material science. The project, which lasted two and a half years, was financially supported by VTT and the Jenny and Antti Wihuri Foundation within the Center for Young Synbio Scientists (CYSS) program headed by Professor Merja Penttilä.

Journal Reference:

Mohammadi, P., et al. (2021) Bioinspired Functionally Graded Composite Assembled Using Cellulose Nanocrystals and Genetically Engineered Proteins with Controlled Biomineralization. Advanced Materials. doi.org/10.1002/adma.202102658.