In a recent study published in the journal Applied Sciences, a team of researchers decorated graphene nanoplatelets (GNPs) with rare earth oxide CeO2 particles to study the decorative effect of GNPs on the strengthening ability of GNPs/Al composites. It was found that the mechanical properties of composites reinforced with CeO2-GNPs were better than those composites reinforced with raw GNPs of the same quality.

Study: Rare Earth Oxide CeO2 Decorated Graphene Nanoplatelets-Reinforced 2024 Aluminum Alloy Matrix Composites Fabricated by Pressure Sintering Process. Image Credits: Production Perig/Shutterstock.com

What are Graphene Nanoplatelets?

Graphene nanoplatelets, or GNPs, are tiny stacks of graphene that can substitute carbon fiber, carbon nanotubes, nano-clays, or other substances. When applied to plastics or resins at a concentration of 2-5 wt%, they make them electrically or thermally conductive and less permeable to gases.

GNPs offer outstanding tensile qualities, strength, and stiffness, as well as desirable functional properties like high heat conductivity and electrical conductivity. They are also lightweight and easy to handle. Because of a distinctive two-dimensional structure, GNPs have a greater specific surface area, which allows them to perform more effectively in load-bearing strengthening applications. For this reason, GNPs are regarded as an effective reinforcement agent in composite materials.

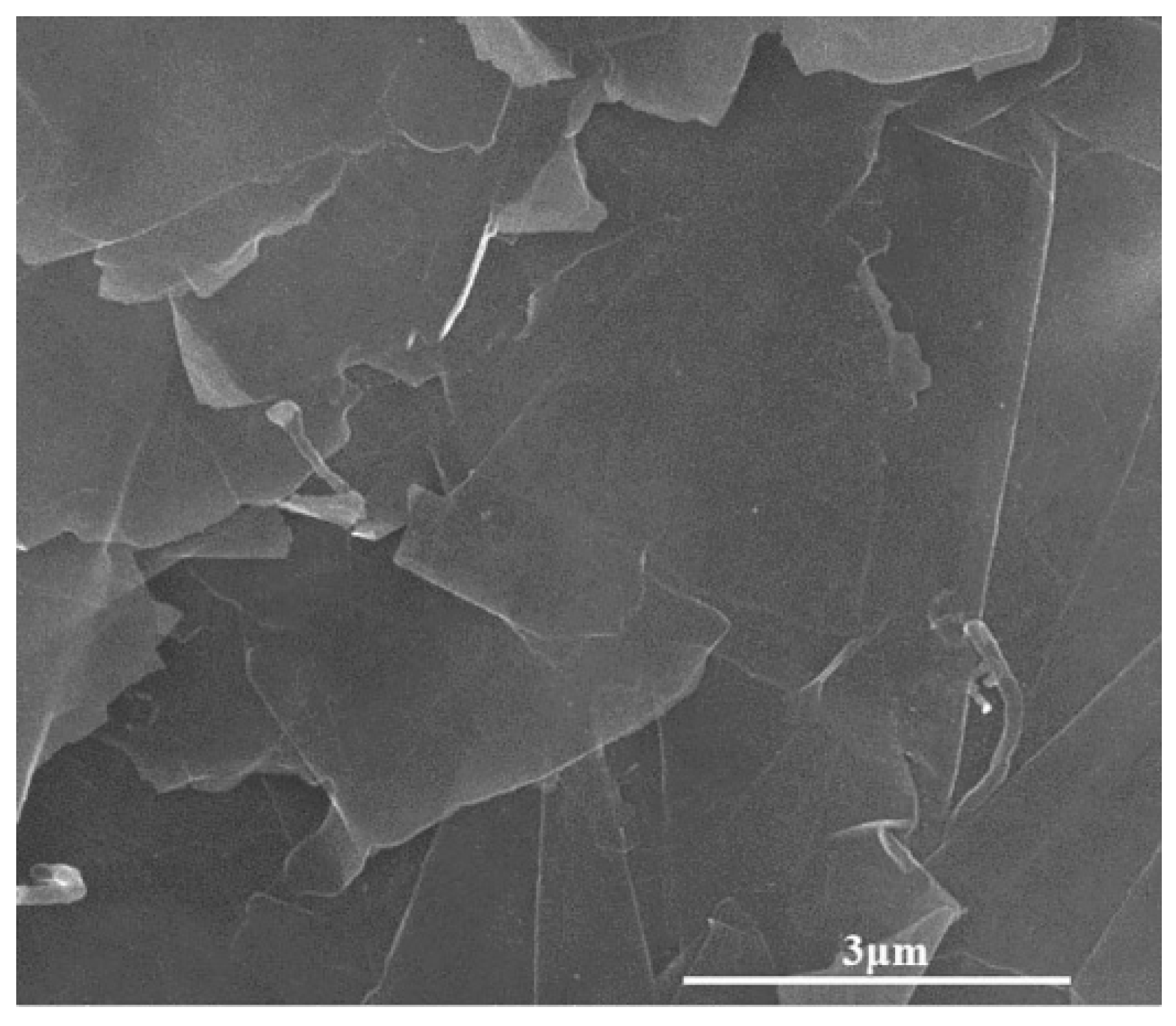

SEM image of the multilayer microstructure morphology of graphene. Image Credit: Guo, Z. et al.

SEM image of the multilayer microstructure morphology of graphene. Image Credit: Guo, Z. et al.

Industrial Applications and Limitations in the Past

In the past, GNPs have been used in structural and functional composites research as an essential new reinforcement material at the nanoscale level. They have also been used extensively as an effective reinforcement in the development of metal matrix composites. Previously, by reinforcing aluminum matrix composites with GNPs, the composites' tensile strength, yield strength, and microhardness were all significantly improved.

Despite advancements in the field of nano-carbon reinforced aluminum-based materials, manufacturing graphene-reinforced metal matrix composites remains a significant difficulty. This is because the force between the graphene sheets tends to cause them to accumulate, which weakens the matrix causing the composites to deform during any load-bearing application.

What did the Researchers do?

In this study, the researchers used surface modification techniques in conjunction with hot pressure sintering to address previously mentioned concerns. The 2024 aluminum matrix alloy was supplemented with natural graphene nanoplatelets and graphene nanoplatelets coated with CeO2 rare earth oxide particles.

Comparative tests were conducted to determine the effect of rare earth oxide-decorated GNPs on the matrix's mechanical properties and microstructure. In the first step, GNPs were decorated with rare earth oxide CeO2 particles using the alcohol heating method. Then, a hot pressure sintering process was used to reinforce aluminum composites with freshly prepared CeO2-GNP particles.

Additionally, the hardness and tensile strength of CeO2@GNPs/2024 AL composites were examined. The sample was subjected to a Vickers hardness test, with a loading force of 0.3 kg and a pressure hold of 15 seconds. The tensile rate was set to 0.5 mm/min for the tensile testing. Ten indentation inspection tests were necessary for each hardness pattern in order to minimize mistakes.

What was Found?

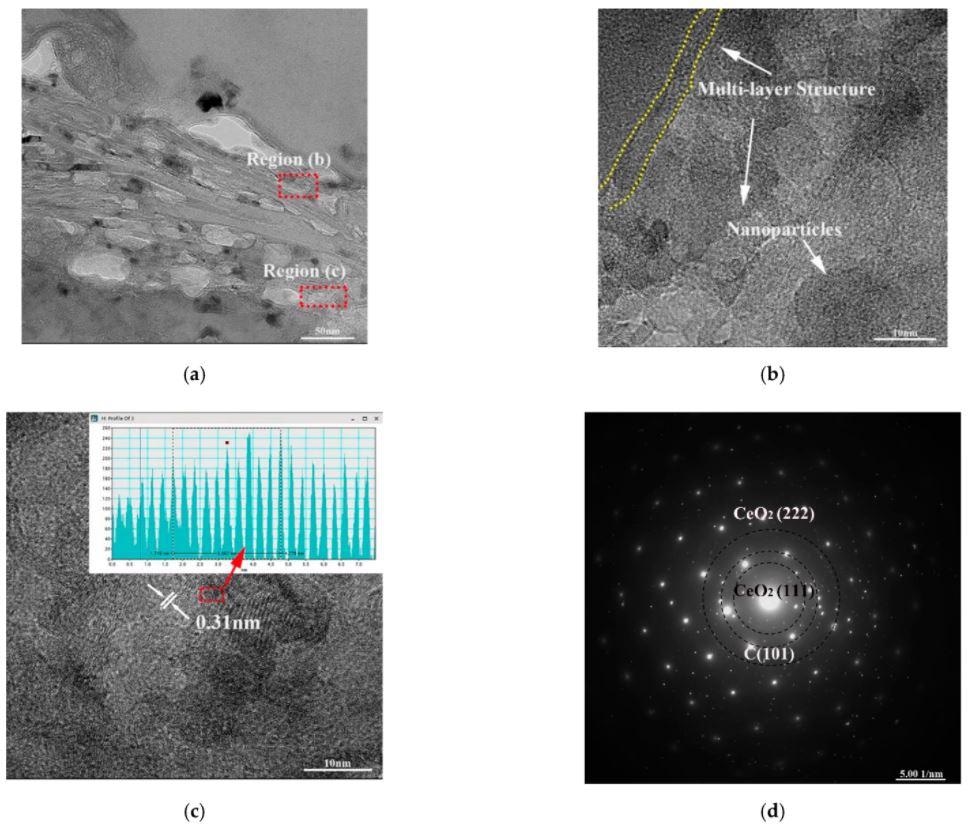

The alcohol heating approach was effectively used to prepare GNPs coated with CeO2 particles. The rare earth oxides CeO2 and GNPs were strongly bonded, and this bonding was sustained even after the pressure sintering technique was used to make the composites.

The decorating procedure increases the dispersibility of GNPs in the matrix. As the wettability between the GNPs and the matrix improves, it encourages the bonding of GNPs and alloy, which reduces structural flaws during the process.

The boundary lines of the GNPs in the matrix did not have any visible pores or defects, such as cracks, along their length. This implies the presence of a sound interface between the GNP and the Al matrix, which is advantageous in improving the mechanical properties of composite materials.

CeO2-GNPs added to composites manufactured under the same preparation circumstances demonstrated a greater grain refinement effect than the natural GNPs. The yield strength and tensile strength of Al-composites reinforced with rare earth oxide CeO2 decorated GNPs were 21.1% and 24.7% higher than the Al-composites reinforced with natural GNPs.

TEM images of CeO2-GNPs/2024Al composite: (a) high-angle annular dark-field image; (b,c) HRTEM image of regions; (c) SAED pattern of Region A; (d) SAED patterns of region (c). Image Credit: Guo, Z. et al.

Significance of Decorating GNPs with Rare Earth Oxide CeO2 Particles

This study presented a novel method of improving the mechanical properties of nanoparticle reinforced aluminum composites. The findings show that because of the decorative effect of rare earth oxide CeO2 particles, the combination of matrix and GNPs has been optimized. When interface bonding and particle distribution in the aluminum matrix are improved, GNPs play a more effective role in a range of strengthening effects, resulting in considerable improvements in the composite's mechanical properties.

Continue reading: Synthesis Techniques of Graphene Oxide: An Overview.

Reference

Guo, Z. et al. (2021) Rare Earth Oxide CeO2 Decorated Graphene Nanoplatelets-Reinforced 2024 Aluminum Alloy Matrix Composites Fabricated by Pressure Sintering Process. Applied Sciences, 11(23), 11177. Available at: https://www.mdpi.com/2076-3417/11/23/11177

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.