The latest paper published in the journal Macromol presents research into the production and characteristics of polymer nanomaterials from vegetable oils reinforced with carbon nanostructures.

Study: Composites of Vegetable Oil-Based Polymers and Carbon Nanomaterials. Image Credit: Aleksandrs Samuilovs/Shutterstock.com

Importance of Polymers

Thermosetting polymers are hydrophobic synthetic polymers that cure to generate 3D networks, allowing their characteristics to be controlled by modifying the intensity of structural crosslinks.

Most industrial thermoplastic polymers, such as synthetic resins and epoxy resins, are derived from hydrocarbons; however, due to natural oil extraction, climate change, environmental pollution, and the rising cost of oil, this is limited.

As a result, considerable efforts have been made to manufacture durable, secure, and ecologically friendly polymers from renewable energy sources.

Sustainable polymeric materials have been synthesized using several starting ingredients, including carbohydrates, vegetable oils (VOs), and peptides.

VOs are the most frequently used because of their intrinsic biocompatibility, ease of production, low cytotoxicity, and inexpensive cost.

Polymers produced with this technique are primarily utilized in the foodservice industry, but other applications include adhesives, foaming agents, coverings, dielectric materials, bindings in the biomedical industry, and as matrix materials in the creation of hybrids.

Limitations

Polymers generated from VOs often demonstrate poor mechanical and tribological characteristics, such as fragility, high gaseous and vapor penetration, and reduced temperature deformation, limiting their practical uses.

Various techniques have been reported to overcome these difficulties, such as combining with other polymers, integrating nanoparticles, and ionized therapies, resulting in bio-nano composites with greater effectiveness.

Polymers from Vegetable Oils

Vegetable oils can be utilized as polymeric primary sources because of their low cost, biocompatibility, cytocompatibility, accessibility, and natural abundance. Furthermore, they are environmentally friendly and help minimize pollutants such as greenhouse emissions commonly produced from fossil fuel sourced materials.

Many VOs undergo modification treatments to enable their use as a monomer, typically by chemical and enzymatic modifications of active sites. However, certain limitations exist in their applications. Polymers have insufficient mechanical strength and permeability attributes, a major hurdle in their industrial utilization.

Rigid nanofillers such as metal and oxide nanoparticles could be utilized to solve this.

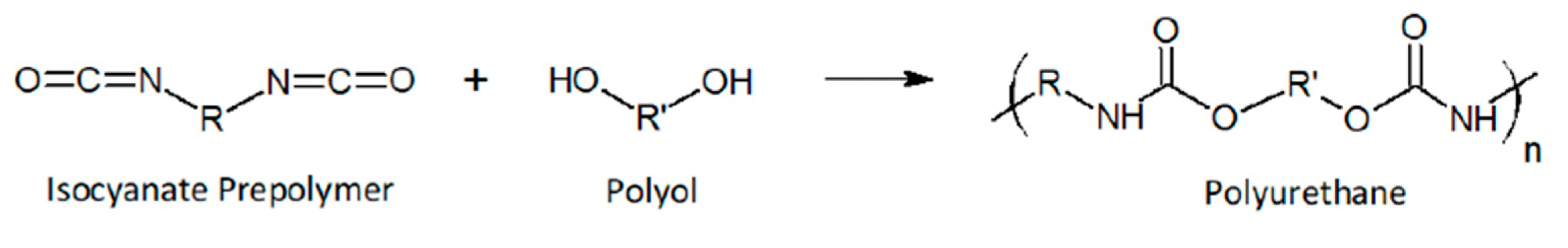

Reaction between diisocyanate and polyol to form a polyurethane. Image Credit: Díez-Pascual, A. and Rahdar, A.

Major Advancements and Chemicals of Vegetable Oils

Polyurethanes (PUs) are a major advancement that are incredibly flexible with multiple characteristics and usage, including varnishes, sealants, epoxies, and polyurethane foam.

The epoxidation of vegetable oils has been a well-known process since 1946, and it is currently gaining popularity due to the strong responsiveness of the ester linkage.

The key benefits of VOs traditional oxidations are the higher efficiency of the process, the low cost of the chemicals, and the method's strong robustness under epoxidation settings.

Limitations

One limitation is that low specificity caused by chemical changes results in contaminants such as hydroxy esters and other oligomers. Second, neutralizing the strong oxidizing acids and watery carboxylic groups produces a large amount of salt. Furthermore, the reaction is very exothermic, which may result in heat escape.

Vegetable Oils with Carbon Nanotubes and Graphene

Carbon Nanotubes (CNTs) have been utilized for reinforcement treatments for various substances. Results show that the addition of 0.28% Multi-walled CNTs increased the 30% modulus of the resin. The single-walled CNT led to an increment of flexural modulus and strength by 45% and 10% respectively.

Graphene has also been utilized for reinforcement and a 1% wt. reinforcement led to a 75% increment in storage modulus and a 34% increase in tensile strength. Carbon and oxygen-based polymerized PU nanocomposites with 0.5, 1.0, and 2.0 wt% GO reinforcement has also been developed.

In short, vegetable oils provide a rich and diverse substrate for biopolymer-based composite. The fundamental problem with VO-based polymers, however, is the efficiency difference with traditional petroleum-based polymeric materials. As a result, significant research efforts are underway to eliminate these disparities.

Continue reading: Graphene Oxide Nanoparticles in Biodegradable Lubricant Synthesis.

Reference

Díez-Pascual, A. and Rahdar, A., (2021) Composites of Vegetable Oil-Based Polymers and Carbon Nanomaterials. Macromol, 1(4), pp.276-292. Available at: https://www.mdpi.com/2673-6209/1/4/19

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.