Single-walled carbon nanotubes (SWNTs) need to be synthesized in a regulated manner before they can be used in different industries. A recent study published in the journal Nanomaterials explains that the maximum yield of SWNT synthesis is dependent on the locations of the materials in a horizontal chemical vapor deposition (CVD) reactor.

Study: Single-Walled Carbon Nanotube Synthesis Yield Variation in a Horizontal Chemical Vapor Deposition Reactor. Image Credit: Evannovostro/Shutterstock.com

The researchers synthesized SWNTs using methane and thin sheets of iron as the source and activator, respectively.

The fluctuation in SWNT production yield throughout the reactor's horizontal distance was investigated using a scanning electron microscope, while atomic force microscopy and Raman spectroscopy were used to characterize the shape and crystalline nature of the synthesized single-walled carbon nanotubes.

Results indicated that the maximum SWNT production yield was achieved in the horizontal reactor's back section.

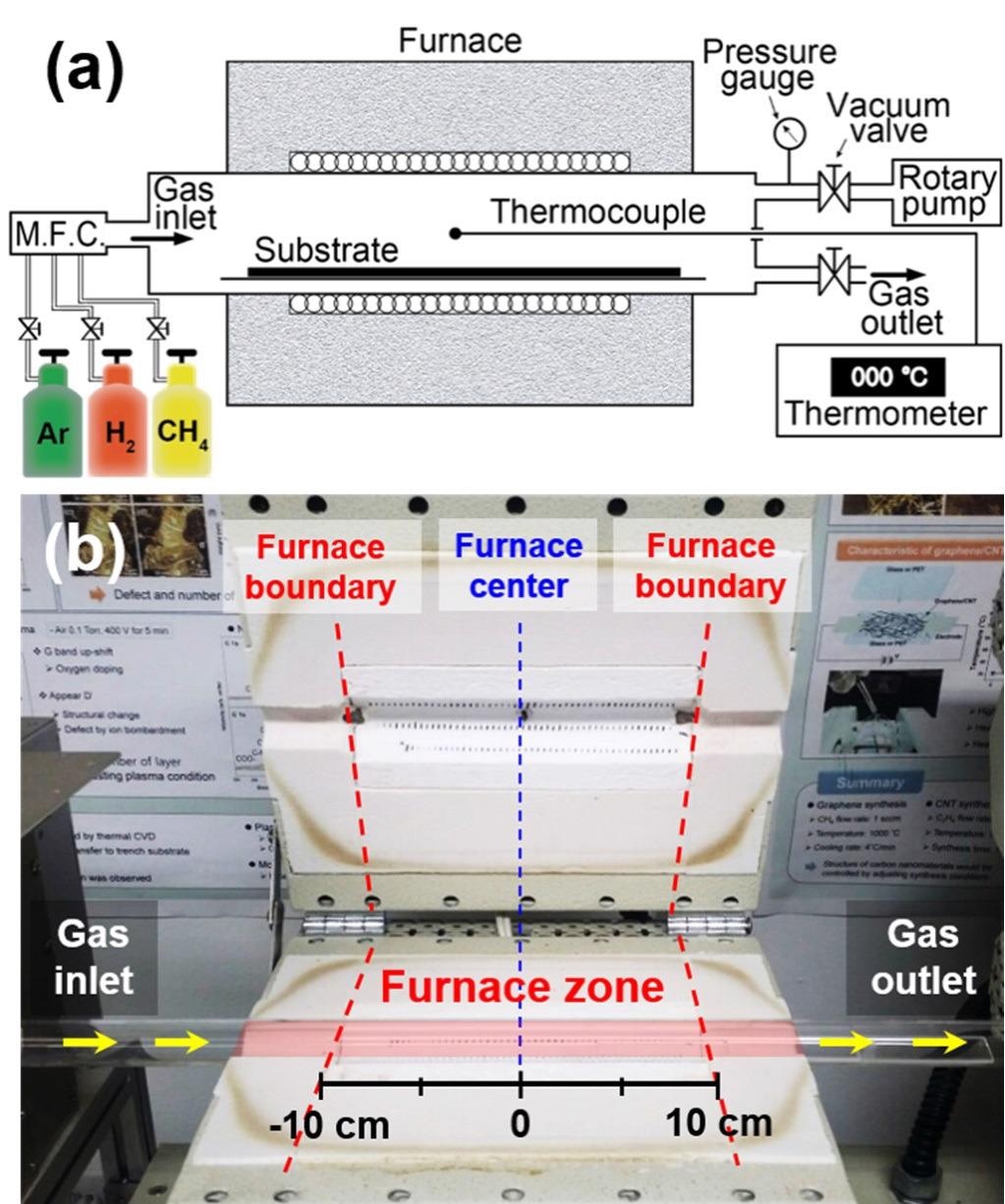

(a) Schematic illustration of the CVD chamber. (b) Digital photo of the apparatus. Image Credit: Sung-Il, J., & Jeong, G.-H.

These findings may be used to produce a variety of single-walled nanomaterials, including conductive nanofibers and rare earth metal nanoparticles.

Applications of Single-walled Carbon Nanotubes (SWNTs)

Single-walled carbon nanotubes have a diverse spectrum of applications due to their exceptional structural, mechanical, and electrochemical characteristics. Controlled production of SWNTs is critical from an industrial standpoint in terms of structural efficiency.

For example, the selective development of semiconducting or ferromagnetic SWNTs is advantageous for applications such as connectors, catalysts, transducers, and technologies that require decent electrical characteristics.

Synthesis of SWNTs Using Carbon Vapor Deposition

Among the different single-walled carbon nanotubes production methods, chemical vapor deposition (CVD) is widely applied due to its simplicity and production control. Additionally, vapor-liquid-solid processes can be used to describe the SWNT production technique in CVD.

Carbon compounds composed from thermally decomposed substrates are incorporated into the reactive metallic particles, which settle as hexagonal networks of highly concentrated carbons to form carbon nanotubes.

Most of the production of single-walled carbon nanotubes in horizontal CVD systems is carried out using growth surfaces installed at the tank center, which gives a high temperature and great thermal stability.

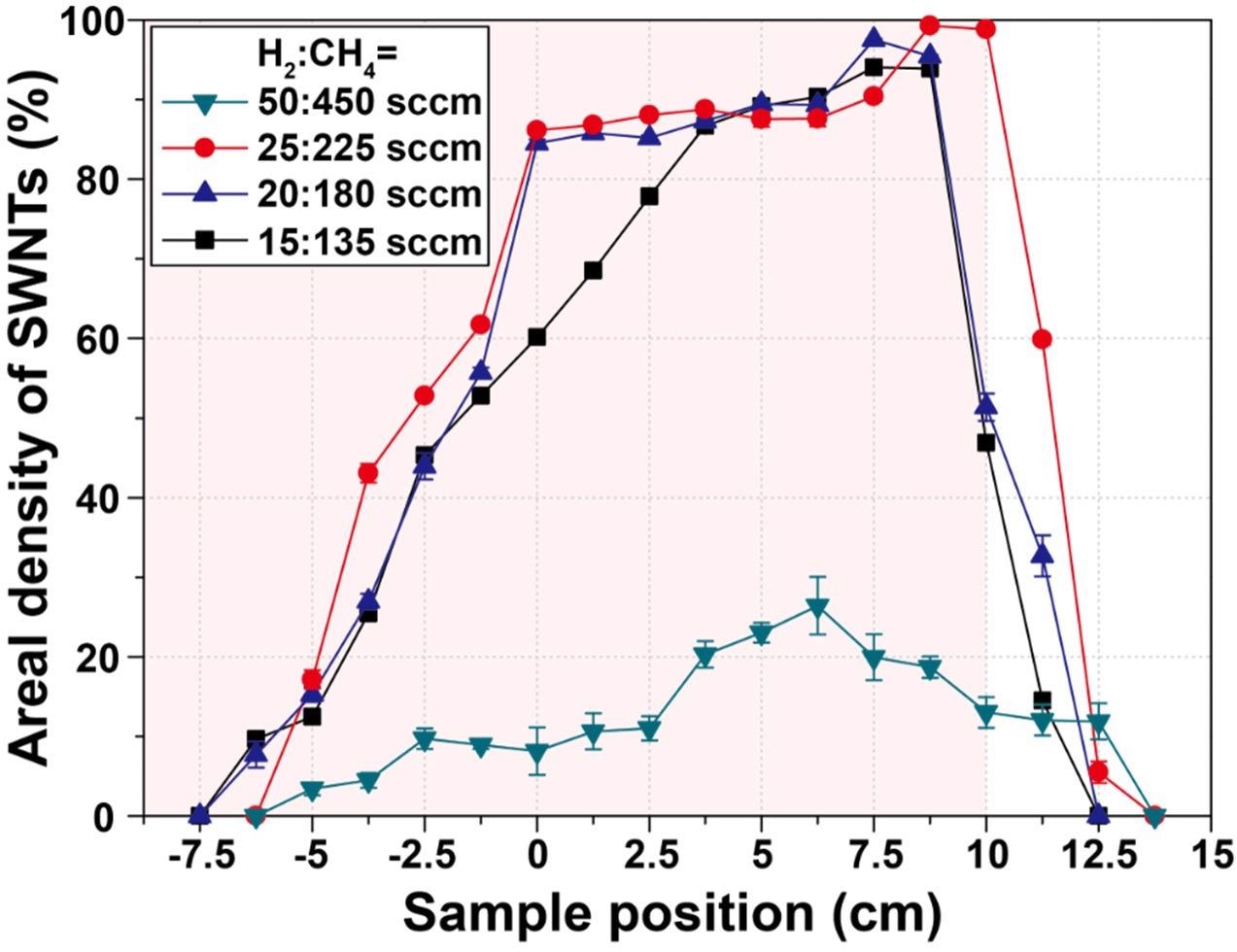

Variation of the areal density of SWNTs with respect to gas flow rate and sample position. Image Credit: Sung-Il, J., & Jeong, G.-H.

A Novel Technique for SWNT Growth on SiO2 Substrates

In this study, researchers concentrated on the development of SWNTs in relation to the sampling point in the CVD tank since the formation characteristics of SWNTs are strongly affected by small changes in the growth conditions like gas flow rate and growth temperature.

The researchers produced SWNTs using thin sheets of iron grown on silicon oxide plates. Iron thin sheets were applied to the substrates with great care using the particle evaporation technique at a slow dissolution rate. After that, the substrates were placed in the tank.

The iron-deposited substrates were then anodized in the air at 900 degrees Celsius for 10 minutes and chilled to temperatures below 200 degrees Celsius.

After stabilizing the chamber, a combination of methane and hydrogen was added for ten minutes to synthesize the single-walled carbon nanotubes.

The CVD heater was cooled to room temperature after the synthesis phase. To examine the influence of gas flow rate and growth temperature at each sample site within the CVD tank the gas flow rate was changed between 150 and 500 sccm while keeping a hydrogen to methane ratio of 10%.

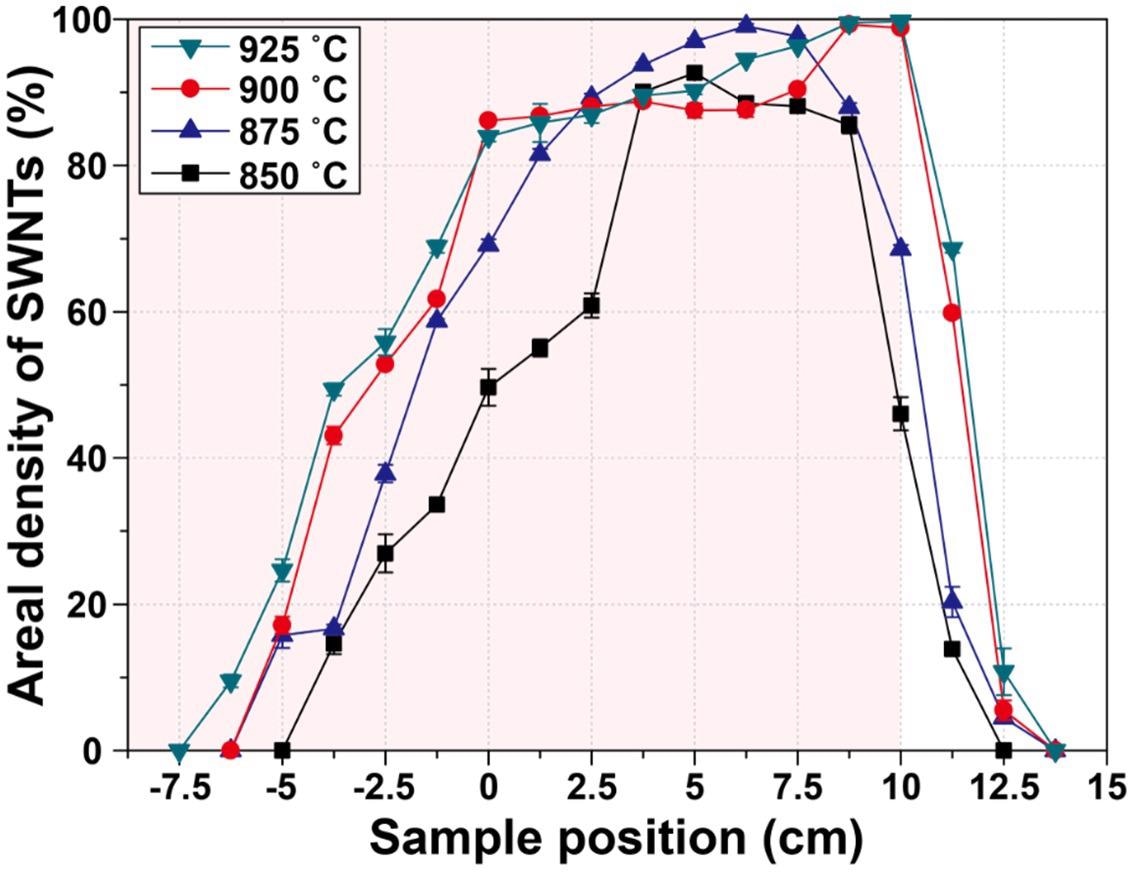

Temperatures were changed between 850 and 925 degrees Celsius for the testing stage.

Research Findings

Based on the findings of SEM, AFM, and Raman spectroscopy, it was discovered that the largest production of single-walled carbon nanotubes was achieved in the back section of the horizontal CVD reactor, not in the middle part.

When silicon substrates and bigger-diameter CVD tanks were utilized, the same results were achieved.

The back portion of the chamber had a greater SWNT concentration than the center owing to the existence of an improved thermal atmosphere that aided in the degradation of the material due to the availability of a gas flow.

The findings presented can be used to synthesize a variety of functional nanomaterials, including semiconducting nanorods and metal oxide nanoparticles, particularly when a horizontal CVD tank is used.

Variation of the areal density of SWNTs with respect to growth temperature and sample position. Image Credit: Sung-Il, J., & Jeong, G.-H.

Future Perspective

To make SWNTs a viable material for sensors, fuel cells, storage systems, and electronics, future research is likely to explore a variety of low-dimensional nanomaterials. Furthermore, comprehensive theoretical calculations based on fluid dynamics research may be necessary.

However, the present research on single-walled carbon nanotubes suggests that they might be used in future applications such as conducting sheets or sensor production.

Continue reading: Carbon Nanotube Nanocomposite Ink for Additive Manufacturing.

References

Sung-Il, J., & Jeong, G.-H. (2021). Single-Walled Carbon Nanotube Synthesis Yield Variation in a Horizontal Chemical Vapor Deposition Reactor. Nanomaterials, 11(12), 3292. Available at: https://www.mdpi.com/2079-4991/11/12/3293

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.