An article published in the journal Materials & Design describes the development of a biodegradable electromagnetic shielding (EMS) material made of graphene/ silver nanocoating and aluminum film paper.

Study: Flexible graphene/silver nanoparticles/aluminum film paper for high-performance electromagnetic interference shielding. Image Credit: ktsdesign/Shutterstock.com

With the widespread use of digital information systems, challenges such as electromagnetic interference (EMI), information security breaches, and electromagnetic wave degradation have developed. In the last decade, versatile electromagnetic shielding (EMS) substances, which filter or deflect electromagnetic radiation, have found applications in EMS textiles, smartwatches, and electrical systems.

Limitations of Previously Used EMS Materials

Rubber and plastic have long been used as substrates for the fabrication of electromagnetic shielding materials. Nevertheless, the limitations of low thermal stability and non-biodegradability prevent them from finding widespread applications.

Cellulose, being the most naturally available energy source in the world, is a great raw substance for making multi-functional composites owing to its recyclability, biosafety, and low toxicity. Cellulose-based substances can be utilized for radiation interference, laminated materials, superconductors, and printed electronics. Even though cellulose paper demonstrates outstanding biodegradability, thermal resistance, and structural stability, its use in the electromagnetic shielding industry is restricted due to its poor electrical insulation.

Numerous nanomaterials have been investigated for use as EMS materials, including CNTs, graphene, and silver nanowires. Some previous researchers have shown that incorporating layered nanostructures into cellulose polymers is an effective method for improving their electrical properties and EMI blocking capabilities. However, a portion of the cellulose filler tends to aggregate, resulting in a reduced functional contact zone during the layered material's formation, severely limiting the material's electrochemical performance. This is detrimental to the process of preparing high-performance EMS materials.

The development of a suitable technique for increasing the functional contact zone of cellulose filler is critical for the production of composite materials with superior electromagnetic shielding effects and thermal resistance.

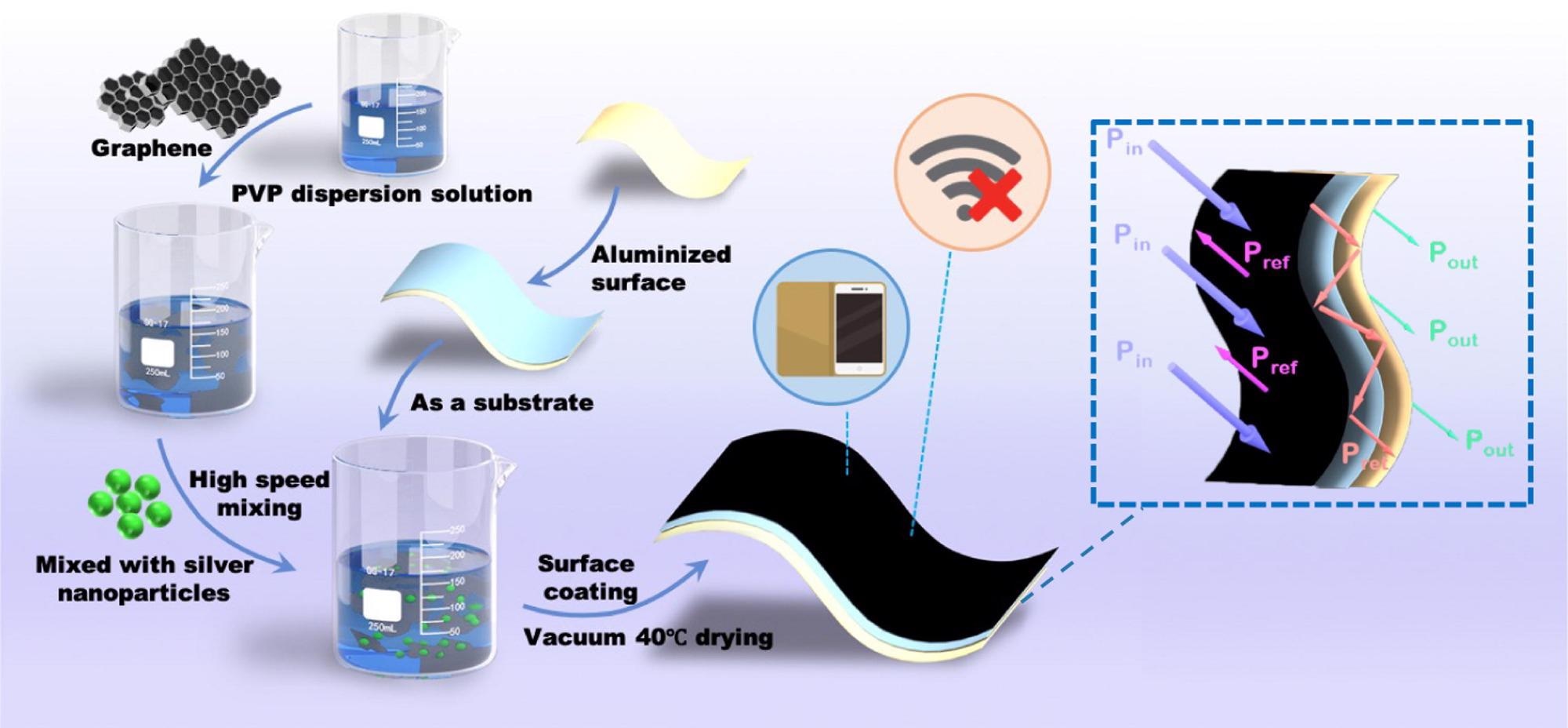

Fabrication of a Biodegradable Paper-Based EMS Material

In this study, the researchers developed a cellulose aluminum film paper with layered nanostructures to attain remarkable electromagnetic shielding properties. In addition to the electromagnetic wave loss surface (graphene/silver nanoparticles coating), the layered composite also had a reflecting surface (aluminum film layer). When it came to the absorption of electromagnetic radiation, graphene played a critical role, and the silver nanoparticles filtered into the core of the coating to form a 3D conductive heterostructure, which aided in the rapid transmission of electrons, increasing the conductivity of the material.

The aluminum film surface collected electrons and energy from the electrical conductive heterostructure and generated a modest quantity of transmission signals back to the graphene/AgNPs layer, boosting the material's EMS effect and thermal efficiency.

Production flow chart of the graphene/AgNPs-coated CAFP. Image Credit: Li, X. et al.

Research Methodology

To begin with, the researchers synthesized silver nanoparticles using a mixture of silver nitrate and 20mL of NaBH4 solution. After equilibrium was reached, the resulting mixture cooled to 10 degrees Celsius and stirred at 10,000 revolutions per minute for 15 minutes.

Silver nanoparticles (AgNPs) were centrifuged and rinsed with alcohol and deionized water before being dried in an oven. A specific quantity of graphene solution, silver nanoparticle solution, and PVP solution was added to a flask and mixed. To create a graphene/AgNPs layer, the solution was shaken for 30 minutes at 2000 rpm.

The aluminum film's base was covered at a thickness of 20–50 nm, bonded to the cellulose paper, and baked. After drying the paper, it was isolated to create a biodegradable paper-based EMS material with a highly charged surface.

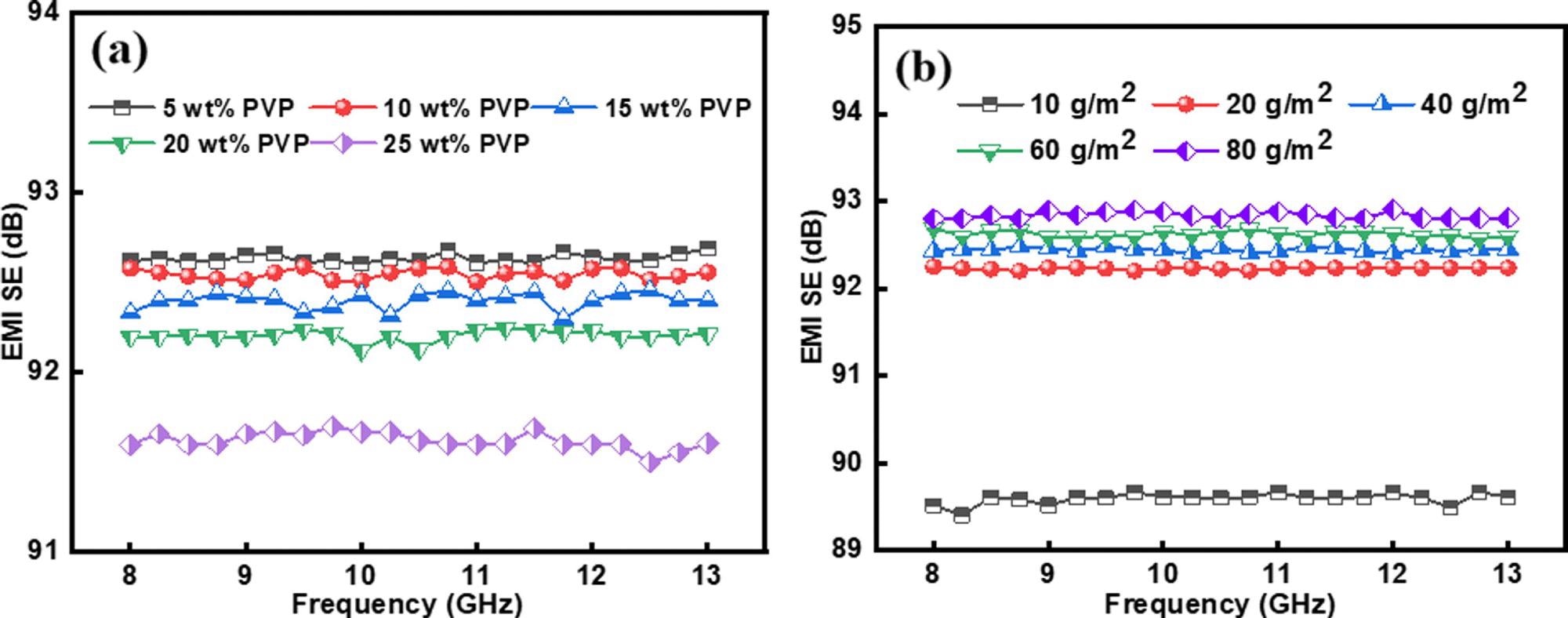

(a) Effect of PVP content on the EMI SE of the CAFP. (b) Effect of coating amount on the EMI SE of the CAFP. Image Credit: Li, X. et al.

Key Findings

The researchers observed that the aluminum film efficiently accepted electrical and thermal energy transformed by electromagnetic radiation and transferred them to a storage medium through the use of a 3D active layer made of silver nanoparticles.

Among the many notable qualities of the produced material were its conductivity, electromagnetic shielding effect, and mechanical properties.

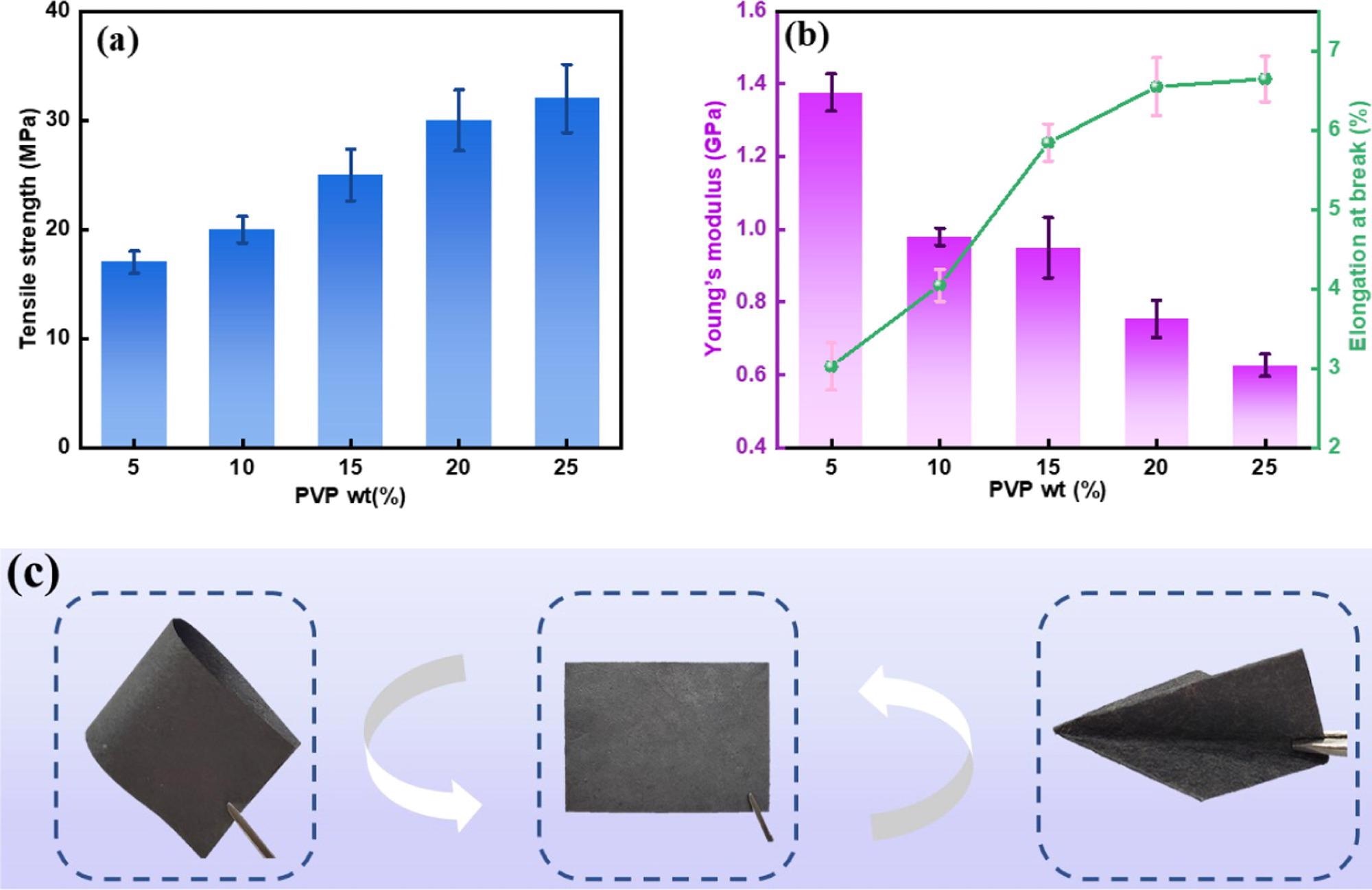

The material had a tensile strength of about 32 MPa and an EMS effect of 92 dB in the frequency range of 8–13 GHz, indicating its suitability for high-frequency applications.

Furthermore, compared to pure cellulose paper, the graphene/AgNPs-coated CAFP demonstrated significantly improved heat transmission capability.

(a) Influence of PVP content on the tensile strength of 20 g/m2 graphene/AgNPs-coated CAFP. (b) Influence of PVP content on the Young’s modulus and the elongation at break of 20 g/m2 graphene/AgNPs-coated CAFP (c) Images depicting the flexibility of the material. Image Credit: Li, X. et al.

These outstanding properties suggest the feasibility of biodegradable paper-based composites to replace rubber and plastic-based electromagnetic shielding materials in the foreseeable future.

Continue reading: Designing New Graphene-Based, Ready-to-Use Formulations.

Reference

Li, X. et al. (2021). Flexible graphene/silver nanoparticles/aluminum film paper for high-performance electromagnetic interference shielding. Materials & Design, 110296. Available at: https://www.sciencedirect.com/science/article/pii/S0264127521008510

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.