The latest study published in the journal Crystal Growth and Design gives a thorough review of the methods utilized to induce kinking and the properties and applications of kinked Nanowires (NWs).

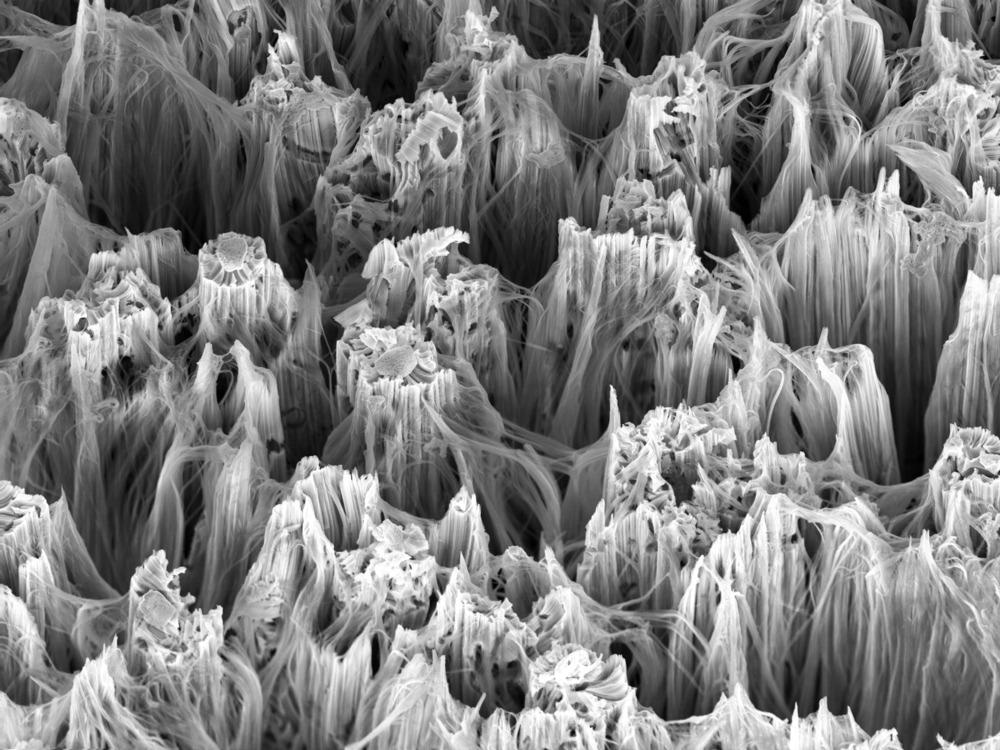

Study: Kinking in Semiconductor Nanowires: A Review. Image Credit: Roberto Lo Savio/Shutterstock.com

The kinking process involves modifying specific environmental parameters such as temperature or pressure, resulting in a variation of the direction of growth of nanowires.

A General Review of Nanowires

Nanowires are 1D solid nanostructures with a high surface-to-volume ratio are one of the most investigated subjects in current material technology. Biochemical sensors, energy-conserving light-emitting gadgets, photovoltaic panels, photodiodes, battery material, logic gates, field-effect semiconductors, and other electronic and photonic devices are all core applications of NWs.

The capacity to tailor the attributes of NWs by altering their constitution, size, lattice parameter, and defect structure is critically attained by kinking.

As critical qualities of NWs can be significantly affected by kinks, smooth and fault-free NWs are preferred in most systems. However, it may provide an NW with entirely new capabilities.

Gaseous antecedents are added to the reaction chamber and are disintegrated on metallic nanoparticles. The antecedent constituents start forming a crystalline seed when the catalyst particles become supersaturated.

The development of the catalyst will follow either the vapor-liquid-solid (VLS) or vapor-solid-solid (VSS) processes, relying on whether it is liquid or solid-state.

Conventional Critical Parameters in Synthesis of Kinked Nanowires

There are a variety of methods for obtaining kinks in NWs. During the reaction, the most popular procedures rely on adjusting certain parameters such as operating temperature and pressure.

The temperature in the reaction chamber is known to affect the growth direction of NWs. If the temperature is changed during the production, the growth orientation of an already developing NW may alter. As a result, the temperature is considered the most basic variable that can be altered.

However, the processes that cause kinking at suitable temperatures may not be readily apparent. Based on the design and approach, kinking can occur at "lower-than-optimal" or "higher-than-optimal" annealing temperatures. It occurs only within a relatively restricted range of temperature, during which the catalyst is predicted to shift from its solid to liquid form.

Another typical component that determines the development direction of NWs is pressure (both absolute pressure and antecedent partial pressure), which is often adjusted throughout the production to produce kinks.

Alternative Kinked Nanowire Synthesis Processes

Modulation of vapor/gas composition is another major synthesis process. During a VLS growing process, the constitution of the environment in the chamber may be adjusted to obtain specific topologies and more complicated compositions such as hetero-structured NWs.

Kinking can also occur due to variations in vapor or gas content, particularly when the antecedent is adjusted. Furthermore, the location of the kink created by this approach may be precisely regulated.

Several investigations have found a definite relationship between the dimensions of the NWs and the likelihood of kinking. Given that the sizes of the kinked NWs in both the VLS and VSS methods are closely connected to the diameter of the catalyst molecules, an additional parameter that may be utilized to modify the quantity of kinked NWs in a specimen is the diameter of the particle.

The amount of dynamic force necessary to cause kinking varies depending on the substrate and hence on the rate of growth, which is frequently governed by the antecedent flow velocity in the tank. Kinked NWs were made via etching in a few studies, a procedure substantially distinct from the VLS and VSS methods.

Properties and Applications of Kinked Nanowires

Various changes occur in the properties of kinked nanowires. Kinked NWs' mechanical and physical properties can have a significant impact on the functioning of nano-electromechanical systems.

Kinks are believed to induce impedance to the transmission of charged particles in NWs. It was discovered that the conductivity is highly dependent on the kink shape. Furthermore, because there are multiple transmission channels, kinked NWs with bigger diameters are likely to be superior conductors.

Nanoelectronic devices composed of different nanomaterials, including NWs, have enormous promise for investigating biological mechanisms. However, most research has concentrated on planar device designs, whereas implementing ultimate point-like and 3D sensors remains a challenge. Kinked NWs may be helpful in overcoming this constraint.

In short, although kinking introduces a few defects, it has piqued the interest of researchers and is considered a powerful technique for fine-tuning the characteristics and morphology of 1-D nanostructures.

Continue reading: Breakthrough for Atomic Arrangement of Amorphous Materials.

Reference

Vlassov, S. et al., (2021) Kinking in Semiconductor Nanowires: A Review. Crystal Growth and Design. Available at: https://pubs.acs.org/doi/10.1021/acs.cgd.1c00802

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.