A recent study published in the journal Biomedical Microdevices focuses on some important factors for the development and production of a microheater, as well as the significance of microheater implementation in COVID-19 diagnostic kits.

Study: Microheater: material, design, fabrication, temperature control, and applications — a role in COVID-19. Image Credit: Drazen Zigic/Shutterstock.com

Heating is important in research, engineering, metallurgy and space exploration, and it may be accomplished by electromagnetic, inductive or microwave radiation. Hot grate or Peltier components can be used for quick shifting and continuous applications. However, they are useless for portable applications or for use in distant places due to their bulkiness.

Heater minimization decreases energy usage and sturdiness, improves thermal sensitivity and can be integrated into various sensors or microarray devices. A typical microheater is 100 nanometers to 100 micrometers thick and has heat ranges of up to 1900 °C with good control. Thin-film microheaters have become a critical research field in recent years as the need for microelectronics has grown.

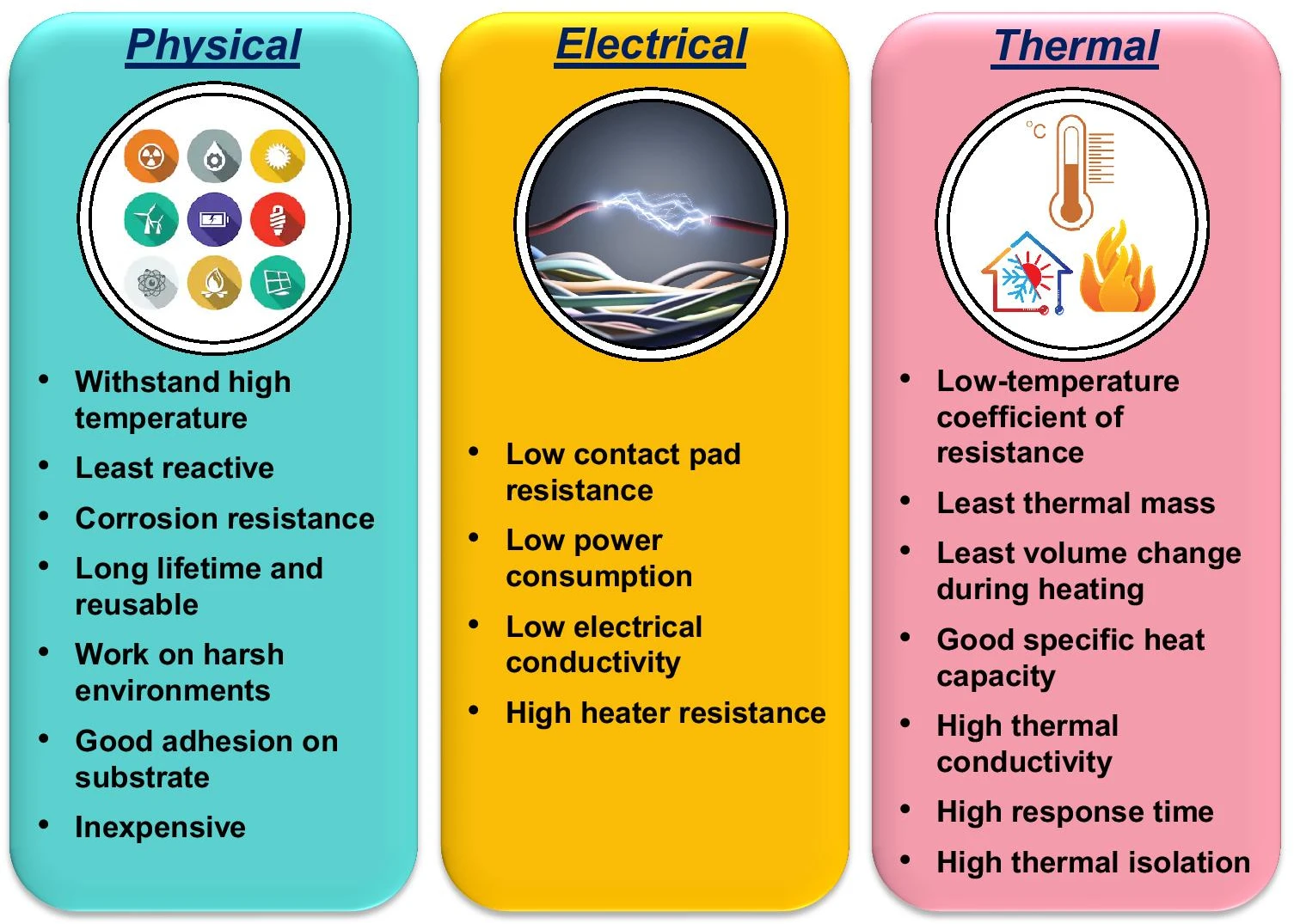

Ideal characteristics of a good microheater. Image Credit: Jeroish, Z. E. et al.

Materials for Microheaters

Rare earth metals, such as platinum, nickel, tungsten and chromium, are the most commonly employed materials for microheaters. Since platinum has a low density, excellent electrical conductance, strong specific heat, low energy usage and good heat detection rates with an impedance that changes linearly with temperature, it is a suitable material for microheaters.

However, platinum cannot be uniformly dispersed on a glass surface. Thus, chromium is coated as an adhesion layer before the application of platinum. Cr has excellent glass adhesion properties and great resistance at higher temperatures, ensuring high responsiveness to temperature-sensing devices.

Microheater Design

The microheater's design is crucial for achieving low energy usage, reduced thermal density, accurate temperature stability throughout the system and improved heat insulation from the external environment. The design of the microheater can range from basic wire or line arrangements to complicated wing-shaped arrangements in order to provide consistent thermal dispersion. Additionally, in certain applications, a solitary microheater is inadequate since a vast heating surface is required. As a result, a microheater array consisting of three or more microheaters is used.

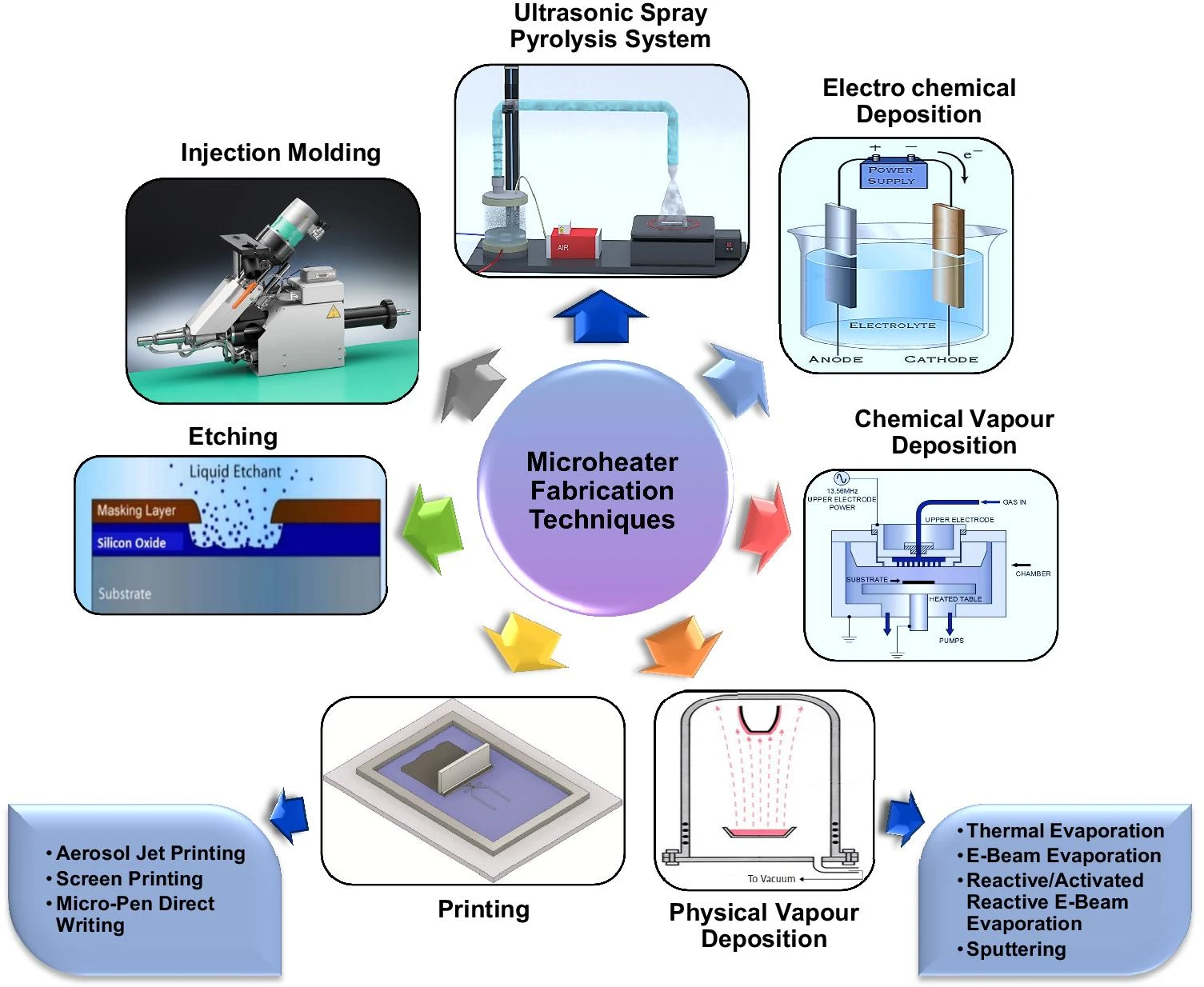

Microheater fabrication techniques. Image Credit: Jeroish, Z. E. et al.

Microheater Fabrication

The manufacturing method, design and cost can be optimized by using the same material and manufacturing technology for the microheater, metal contact and resistance temperature detector (RTD) sensors. Numerous techniques are used for the fabrication of microheaters, including PVD, CVD, electrochemical deposition, injection molding and printing.

Physical vapor deposition (PVD) is the simplest approach for fabricating microheaters. It is a vacuum deposition technology that employs thermal evaporation to form a thin coating on the appropriate substrate to improve corrosion behavior and optical characteristics. Thermal energy provided to the original source melts the sample and increases the vapor pressure of the gaseous plasma, which tends to discharge or collide with elementary particles, condensing or accumulating the targeted atoms on the substrate.

Microheaters are also manufactured using the chemical vapor deposition (CVD) process. This is because polysilicon's high resistance makes it ideal for heating components. It is, however, difficult to install using a standard PVD method since it must be chemically placed on the substrate. CVD allows for the creation of a homogeneous, continuous, large contact area with excellent adhesion and no flaws or contaminants.

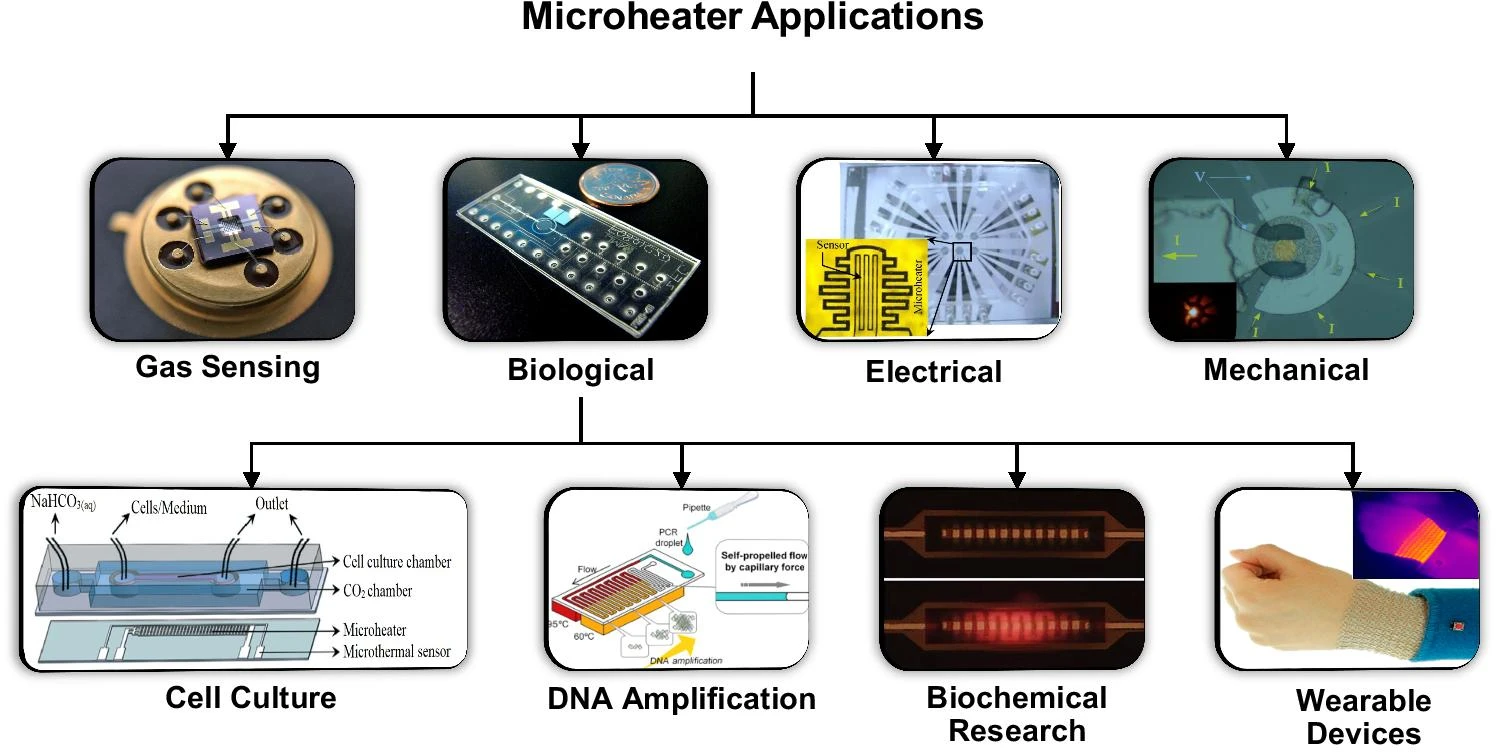

Potential applications of the microheater. Image Credit: Jeroish, Z. E. et al.

Role of Microheaters in COVID-19 Pandemic

RT-PCR is currently the standard method for diagnosing COVID-19. RT-PCR is particularly efficient and sensitive when it comes to identifying viral genotypes as it can identify a solitary RNA molecule in a single reaction. However, it can only be conducted in state-of-the-art labs equipped with desktop-sized thermocyclers, limiting its use in resource-constrained environments. When fighting a pandemic, testing must be conducted quickly and precisely to prevent a patient that has tested positive from being released early and putting others at risk.

Thus, the use of micro heaters is required to build simple and affordable testing kits that enable at-home diagnostics. LAMP is a rapid, easy-to-use and cost-effective diagnostic tool that uses microheaters and can probe several locations of COVID-19 RNA in a single reaction. The introduction of COVID-19 test kits based on LAMPs with integrated microheaters could allow on-site viral diagnosis and prevention.

Additionally, disposable and low-cost microheaters using minimal substrates and heater materials have applications in a variety of critical domains, including gas sensing and biomedical industries.

Reference

Jeroish, Z. E. et al. (2021) Microheater: material, design, fabrication, temperature control, and applications—a role in COVID-19. Biomedical Microdevices. Available at: https://link.springer.com/article/10.1007/s10544-021-00595-8

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.