Research published in the journal Polymers has explored the production of chiral nematic cellulose nanocrystal (CNC) films for enhancing the optical properties of multi-functional materials.

Study: Chiral Nematic Cellulose Nanocrystal Films Cooperated with Amino Acids for Tunable Optical Properties. Image Credit: Christoph Burgstedt/Shutterstock.com

Chiral nematic cellulose nanocrystal (CNC) films can be produced by including various amino acids. These films exhibit excellent luminescence and reflectivity, which may be adjusted by the number of amino acids supplied. Additionally, the nanocomposite films possess remarkable ultra-violet radiation shielding properties in various wavelength ranges, demonstrating multi-optical functionalities.

Importance of Cellulose Nanocrystals (CNCs)

Cellulose is among the most common organic compounds in the environment and has tremendous potential for biotransformation and the manufacture of useful polymeric materials.

Cellulose nanocrystals (CNCs) are compounds of cellulose macromolecules that can be isolated through a hydrolysis process. Rod-shaped CNCs provide excellent bioactivity, durability, high young’s modulus, a tuneable architecture, and the capacity to modify the surface. Additionally, CNC solutions can self-assemble into chiral nematic layers at specific aqueous concentrations.

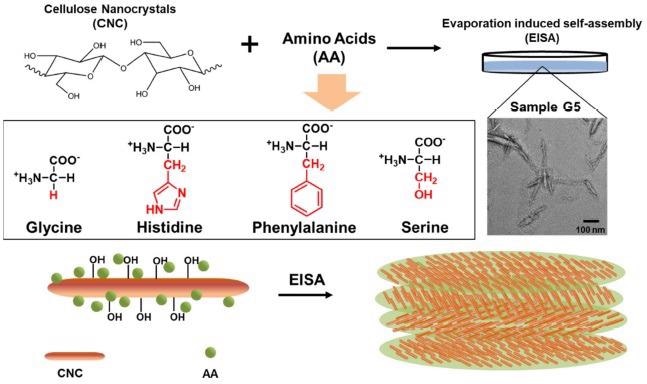

The scheme of the CNCs–AA composite films preparation: the molecular structures of four types of AAs; TEM image of sample G5 suspensions; and the proposed model for CNCs incorporated with AA particles during EISA. © Xiao, X. et al. (2021).

Due to their unique configuration, the CNC films generated by evaporation-induced self-assembly (EISA) scatter the polarised light, and the films exhibit remarkable refraction and luminescence. In recent times, chiral nematic CNC films have shown significant promise in a variety of industries, including detectors, encryptors, laser filters, and stencils.

Modifications for Increasing Toughness of CNCs

The CNC-based films are usually brittle and have low toughness due to the high stiffness of cellulose nanocrystals. Organic compounds, such as glycerol, can be used as fillers to solve this issue. When compared to standard CNC-based manufactured polymeric materials, CNC-based bio-composites demonstrate an excellent combination of regulated color appearances and enhanced mechanical capabilities.

The toughness of CNCs can also be increased by combining carbon nanocrystals and glucose. This causes the CNC chains to reorganize and the repelling relationship to intensify, raising the helical pitch of the chiral nematic composition and altering the visible hue of the films. In addition to increased structural rigidity, the films show a reversible color shift from blue to red, which is beneficial in multiple industrial applications.

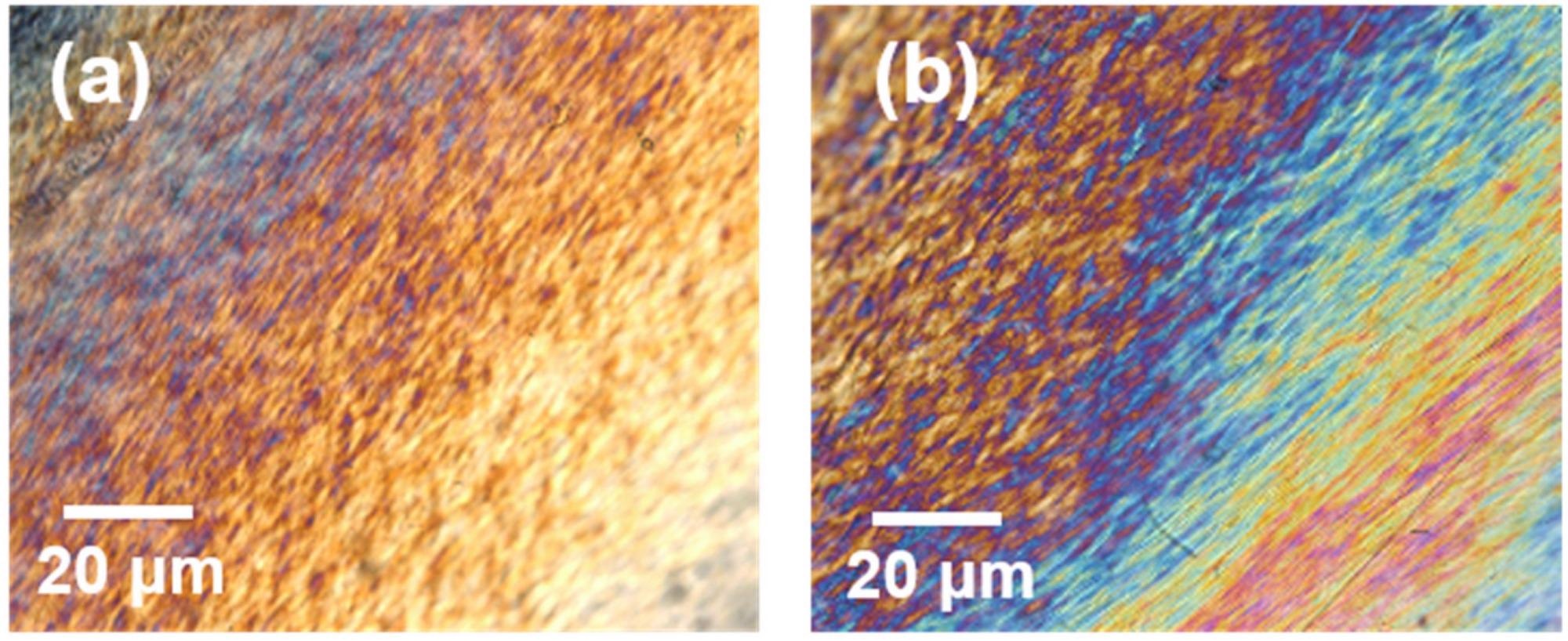

POM observations of the pure CNC film: (a) the center region and (b) the edge region. © Xiao, X. et al. (2021).

CNC Films Incorporated with Amino Acids

CNC films incorporating the most basic component of living organisms (amino acids) have garnered a lot of attention in recent times, thanks to the growing interest in bioinspired and biodegradable materials. The CNC films made with this approach not only have excellent thermomechanical qualities but also have a distinct luminous hue that shifts from blue to yellow-red depending on the amino acid profile.

Even though the research on CNC–AA films has shown some intriguing findings, there are still some issues in their fabrication process, such as polarised chirality and uneven AA composition ratios.

In this work, four different forms of amino acids (glycine, histidine, phenylalanine, and serine) were combined with CNCs in different ratios to make hybrid films by the EISA method. The photonic, structural, and molecular characteristics of the material were studied using different characterization methods. Various properties other than luminescence were also investigated to find broader applications for reusable CNC composite films.

To make a solution with a solid concentration of 1%, the amino acids were separately dissolved in distilled water. CNCs and AA mixture was mixed to create a blended CNCs–AA solution. To obtain cellulose nanocrystal films integrated with amino acids, the blended CNCs-AA solution was magnetically agitated at room temperature for 10 hours.

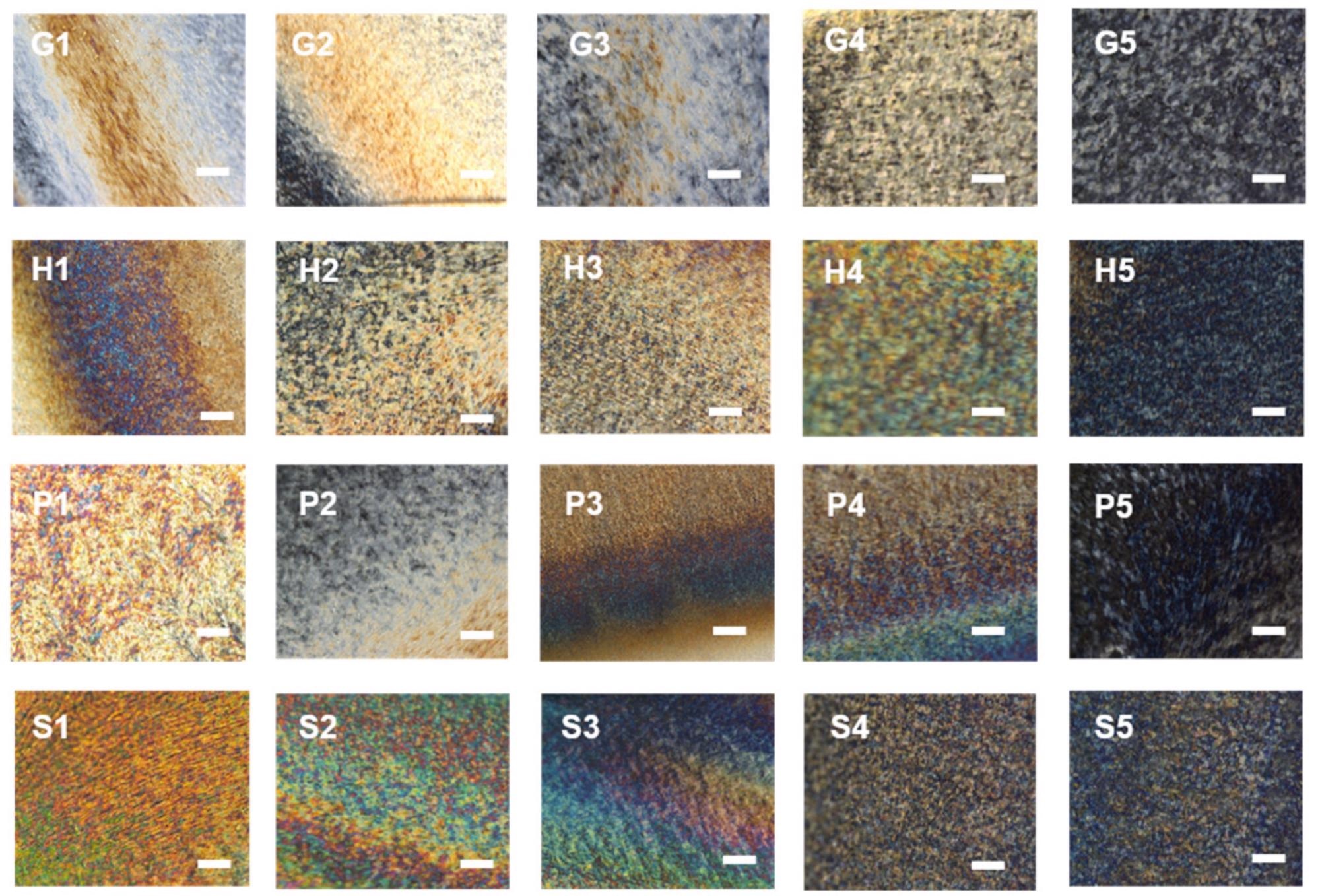

POM observations of the CNCs-based films incorporated with glycine, histidine, phenylalanine, and serine, with different AAs additions. Scale bar = 20 µm. © Xiao, X. et al. (2021).

Research Findings

The researchers discovered that CNC-AA films exhibited remarkable luminescence and refraction characteristics. The successful incorporation of amino acids into films of cellulose nanocrystals was confirmed by structural characterization. The intercalations disrupted the morphology of the films' cross-sections, expanding pitch levels and increasing the reflected wavelength's red-shift.

Serine was found to be the most suitable amino acid for physical adsorption into cellulose nanocrystals while the UV light-shielding properties of histidine and phenylalanine composite films were excellent across a wide range of wavelengths. The various processes of CNC–AA interactions resulted in distinct microstructural configurations, which produced the distinctive optical characteristics of the composite films.

The described production of cellulose nanocrystal films incorporated with amino acids could aid the development of novel multi-functional materials.

Continue reading: The Applications of Nanoparticles as Synthetic Catalysts.

Reference

Xiao, X. et al. (2021). Chiral Nematic Cellulose Nanocrystal Films Cooperated with Amino Acids for Tunable Optical Properties. Polymers, 13(24), 4389. Available at: https://www.mdpi.com/2073-4360/13/24/4389

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.