Recently, an article was published in the journal Materials, which explores the potential of using polymer nanocomposites for use in bone implants.

Study: Microstructure and Mechanical Properties of Inverse Nanocomposite Made from Polylactide and Hydroxyapatite Nanoparticles. Image Credit: Monstar Studio/Shutterstock.com

Polymer nanocomposites are used in a wide array of applications, ranging from chemical sensors and medical implants to smart memory devices.

As of now, no effective method for the regeneration of large, or so-called critical, bone losses has yet been discovered.

The key challenge in developing such solutions is to create an implant that combines osteogenic characteristics with structural strength and a predictable degradation profile. The research team’s goal was to develop a resorbable material with optimal porosity, adequate strength, and elastic properties while having a stimulated renewal tissue by a modulus that matches that of the bone.

In this study, the team explored the concept of inverse nanocomposites, which have a considerably larger amount of ceramic content as compared to polymer nanocomposites and offer sustainable alternatives to bionic arms and bone implants.

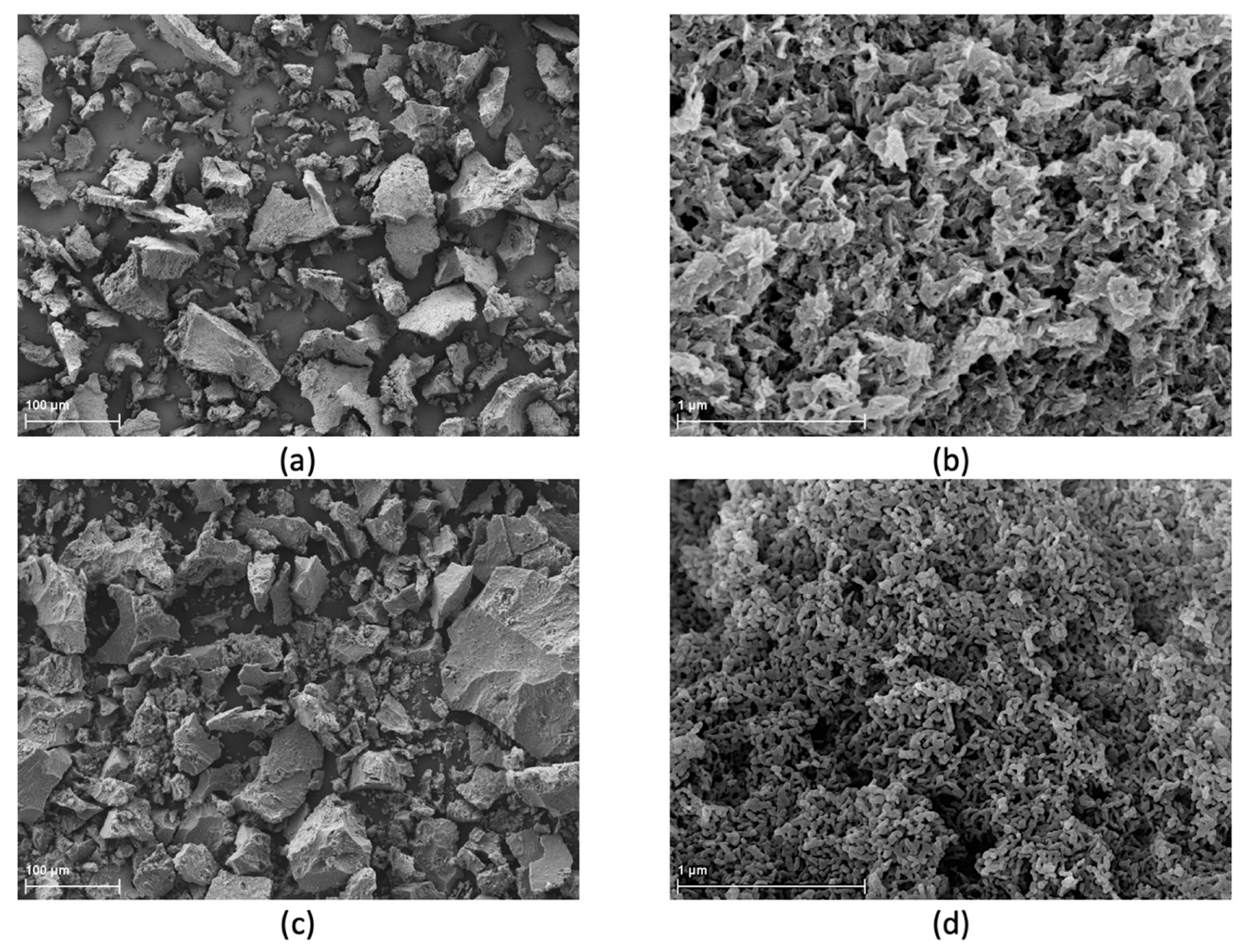

SEM micrographs of powder (a,b) raw HAP NPs, (c,d) heated HAP NPs. © Pietrzykowska, E., Romelczyk-Baishya, B. et al. (2022)

How are These Materials Created?

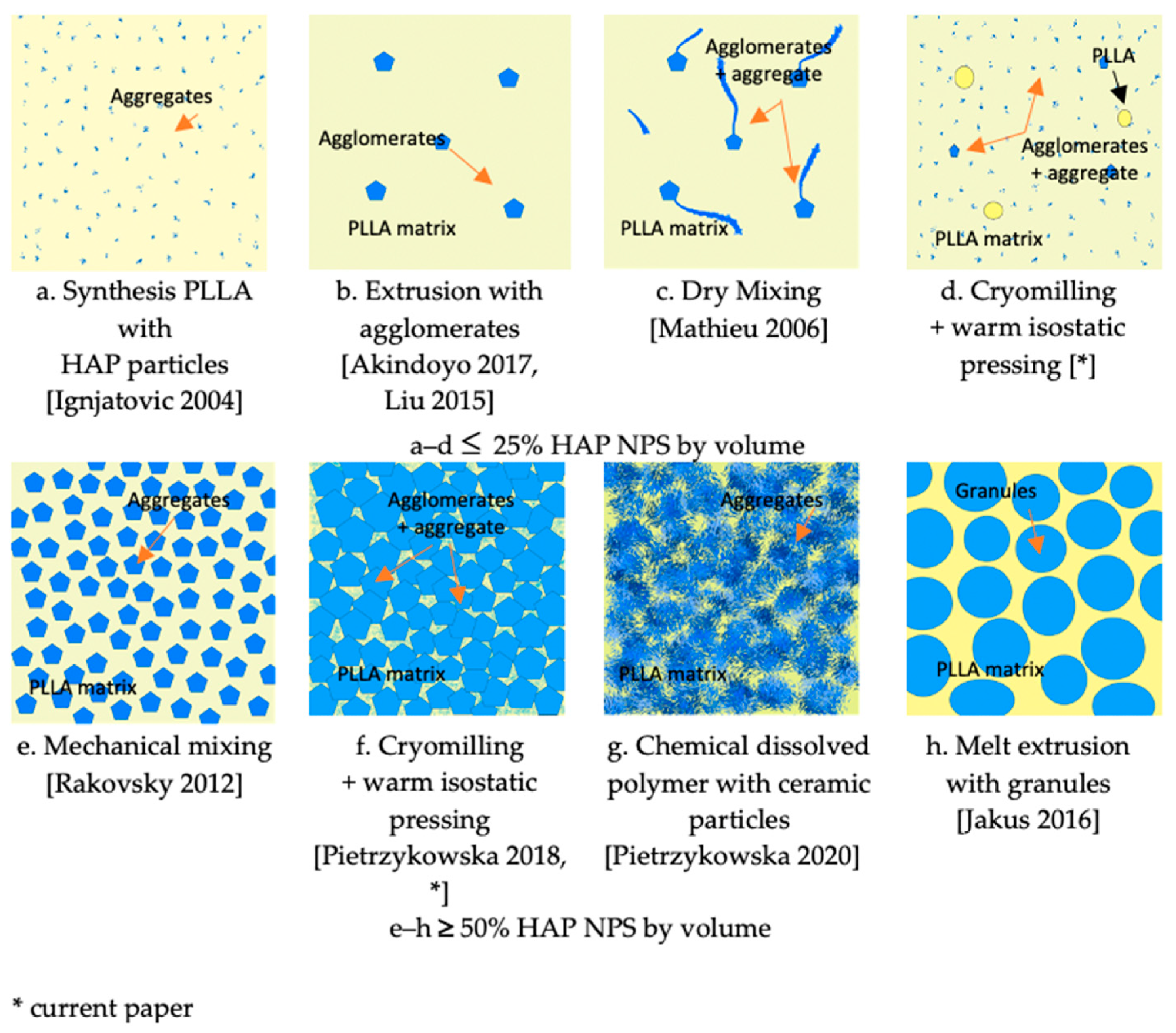

This research used cryomilling and a heated isostatic pressing approach to create inverse nanocomposites made of bioresorbable nanocrystalline hydroxyapatite (HAP NPs) and polylactide (PLLA). A two-stage approach was used to create the samples.

First, a combination of microparticles and nanoparticles were milled at cryogenic temperature (cryomilling), resulting in composite pellets, and then these pellets were isostatically pressed under pressure (Isostatic Pressing Approach). A key technical difficulty was to limit the amount of moisture in the composites created, which mostly came through the surfaces of HAP NPs.

The porosity of these materials may be controlled by altering the consolidation pressure, runtime, and heating. These parameters may be changed according to the sample profile. Using a series of carefully crafted steps and strictly ensuring quality checks, the team was finally able to create the inverse nanocomposite sample and subjected it to further testing to determine its usability in orthopedics and similar applications.

The Best Contender for Regrowth of Bones

The following HAP NP compositions were investigated: 25%, 50%, and 75% HAP NPs by volume. These composites' mechanical characteristics and structure were investigated.

In terms of compressive strength and porosity, it was observed that a volume content of 50% was ideal. The compressive strength of this inverse nanocomposite was the highest, with a contact angle of 50° and 25% porosity, making it a contender for further research as a bioresorbable bone implant.

At this stage it is worth mentioning that the structural rigidity of the material is inversely proportional to the porosity of the material i.e., more porous materials have lower mechanical strength.

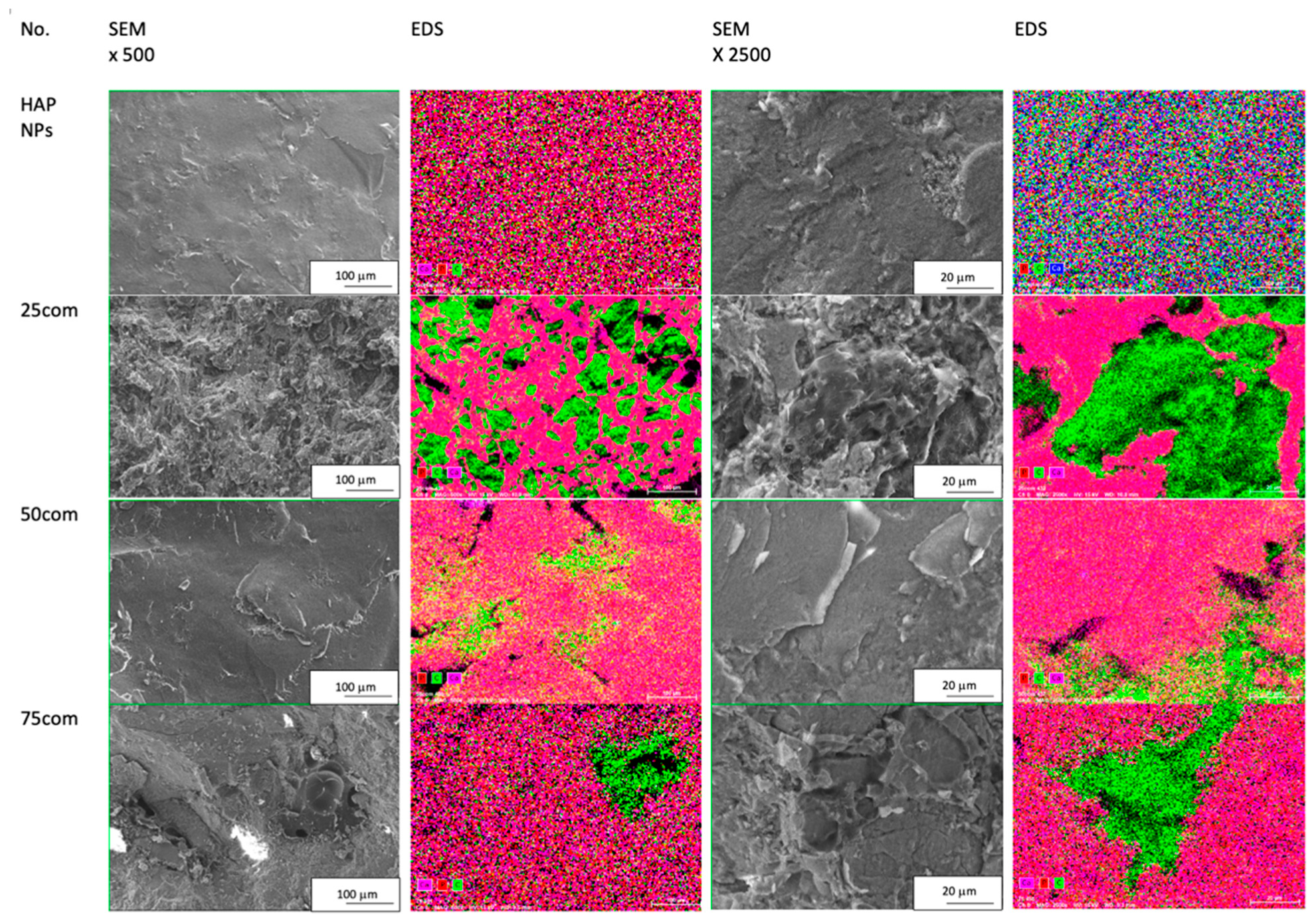

Collection of SEM images; EDS mapping for HAP NPs sample and 25com, 50com, and 75com composites. © Pietrzykowska, E., Romelczyk-Baishya, B. et al. (2022)

Interesting Properties Observed

After cryomilling, the composite granulates formed had an uneven shape. The specific surface area of sample granulates increased as the number of HAP NPs increase and fragmentation decrease. Furthermore, a diffractogram analysis revealed that the sample was crystallized and phase pure. A difference in peak width was observed which correlates to a minor increase in hydroxyapatite particle size.

The microstructure of the composite varied based on the chemical composition, i.e., variations in the ratio of PLLA to HAP NPs were observed by the investigators. The volume content of the manufactured inverse nanocomposite was twenty-five, fifty, and seventy-five percent, respectively, and following the heated isostatic pressing, variations on sample fractures were noticed.

When the contact angle for the manufactured sample was examined, a distinct reduction in hydrophobicity of the composite was observed as the number of HAP NPs increased. Here the contact angle for PLLA sample was 70 degrees, whereas the HAP NPs sample had a contact angle of 24 degrees. The composites' performances were proportionate to bioactive ceramic content and generally ranged between these levels.

Schematic structures of composites based on bioresorbable polymers depending on calcium phosphate quantity and method of obtaining. © Pietrzykowska, E., Romelczyk-Baishya, B. et al. (2022)

The Future and Beyond

The goal of this research was to figure out how hydroxyapatite nanoparticles affect the structure and characteristics of nanocomposites. Through cryomilling plus warm isostatic pressing, the authors provided a patented process (CMWIP) for the production of inverse nanocomposites.

The next step would be to improve the composites' biocompatibility and match the nanocomposites' breakdown rates to the frequency of new bone development. This objective appears to be doable by altering the polymeric component of the composite materials.

While acceptable mechanical qualities have been attained, the fundamental restriction of bioresorbable implants is their long-term permanence, which must be regulated to the rate of bone tissue regeneration over time.

Continue reading: Neuroprosthetics and Additive Micromanufacturing – Enabling a Cyborg Future?

Reference

Pietrzykowska, E., Romelczyk-Baishya, B. et al. (2022). Microstructure and Mechanical Properties of Inverse Nanocomposite Made from Polylactide and Hydroxyapatite Nanoparticles. Materials, 15(1). Available at:https://www.mdpi.com/1996-1944/15/1/184

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.