The journal Results in Chemistry has published an article focusing on the utilization of Taguchi strategy to analyze ideal operating settings by fueling the engine with a biodiesel composed of Carbon nanotubes (CNTs) combined with peanuts oil.

Study: Energy and exergy analysis and multi-objective optimization of a biodiesel fueled direct ignition engine. Image Credit: Scharfsinn/Shutterstock.com

Shortage of Fossil Fuels and Biodiesel

Fossil fuels are one of the primary sources used to meet the world's power needs.

As the world's enhanced energy consumption, there has been a tremendous spike in their requirements.When contrasted to industrialized nations, developing nations face a major concern of fossil fuel shortage. Biodiesel has attracted substantial attention from the research community due to its thermal efficiency as a sustainable energy source. Nanoparticles and exhaust systems have been employed to lower diesel pollution because of their operational excellence. Metal nanoparticles, in particular, have gained popularity.

Advantages of Addition of Nanoparticles to Combustion Engines

The inclusion of metal nanoparticles accelerates the rate of burning and lowers the emission of hazardous pollutants.

The large surface-to-volume ratio of the nanoparticles is the chief factor for their low greenhouse gas emissions. Ignition properties improve when the surface area-to-volume ratio increases due to a better fuel and oxygen interface. Furthermore, the rate of extraction and the injection timing are sped up.

Nanoparticles can also be used as auxiliary transporter to boost powerplant burning and performance metrics, and contain several special qualities that enhance the physicochemical characteristics of the fuel, resulting in enhanced combustion and lower engine pollutants.

The thermodynamic efficiency of liquid fuel combustioncan also be boosted with their use; metal-based nanoparticles improve combustion while lowering the production of hazardous pollutants.

Physical and Chemical Methods for Nanoparticle Dispersion

To obtain the high durability of nanoemulsion in diesel, two processes are often used: stirring and the use of fine particles.

The usage of tiny nanoparticles can be efficient and quickly disseminated, and the procedure is easier than blending. The greater the mixing period, the more stable the nanoparticles.

Biochemical approaches, in addition to the physical techniques, are utilized to stabilize the fuel. It was discovered that pH is a factor affecting nanoparticle durability and that adding algal concentration improves engine efficiency by increasing carbon production.

Addition of Hydrogen

Dispersing hydrogen to a diesel engine improves the blending time of air and fuel, which may result in enhanced ignition and less NOx generation.

As hydrogen is a carbon-free fuel, there should be no constraints on its usage in internal combustion engines. However, raising the percentage of hydrogen in an engine enhances the thermal emission rate and chamber pressure, both of which enhance nitrogen oxide generation. The biggest drawback of using hydrogen as a secondary fuel in conventional diesel engine chambers is pressure rise and ignition disturbance.

What is Taguchi’s Method

Although hydrogen and nanoparticles minimize pollutants with excellent performance statistics, additional steps must be performed to identify the ideal condition.

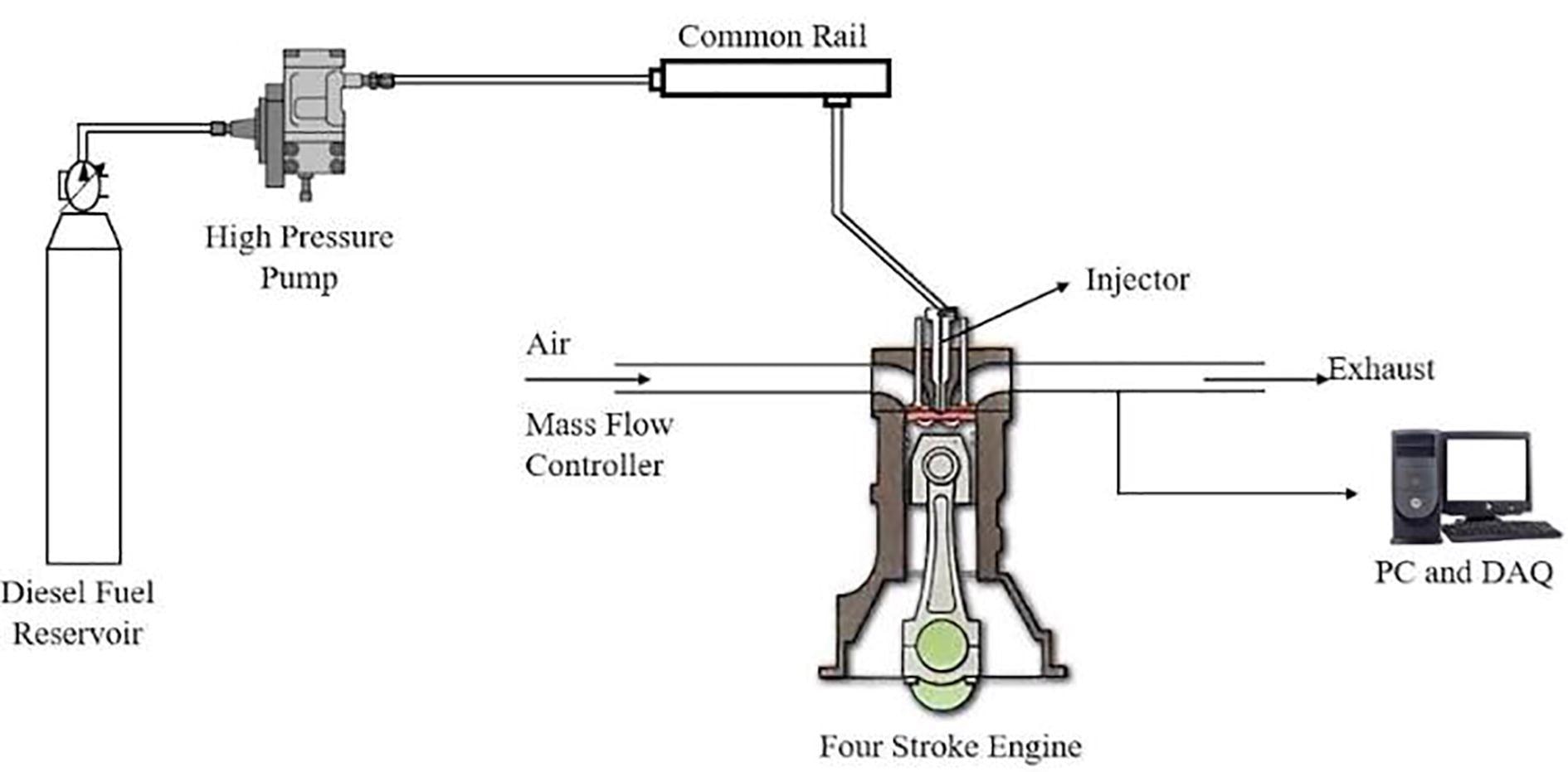

Taguchi's approach is used to estimate burning and exhaust emissions. For the research setup, the Taguchi approach is utilized. It is a statistical approach for increasing engine efficiency, and is based on the attribute of signal-to-noise ratio. Taguchi is shown to be the best approach, with a confidential range of 95% and a time consumption reduction of 65%.

Layout of experimental setup. © Raja, S. et al., (2022)

Research Findings

The results demonstrate the effectiveness of combustion pressure - 240 bar and spark ignition - 21 with 25ppm of CNTs in 20% biodiesel at 100% load delivers the highest thermal efficiency associated with brake.

As the engine load increases, so does the thermal performance of the brakes. Meanwhile, boosting the biofuel mixture improves brake thermal performance by acting as an oxygen booster. It was discovered that when the proportion of biofuel mix rose, the brake-specific fuel consumption decreased due to the increasing mass flow rate.

In general, as vehicle load enhanced, so did the generation of nitrous oxides. The inclusion of biofuel blends and CNT nanomaterials in biodiesel fuel lowered carbon monoxide emissions by increasing the oxygen concentration during the burning process.

To summarize, it was discovered that the introduction of peanut biodiesel mixture and CNT nanostructures had a massive impact on performance and combustion specifications such as brake thermal efficiency (BTE) and brake specific fuel consumption (BSFC) while reducing pollution of hydrocarbons, carbon monoxide, and NOx.

Continue reading: Can Nanoparticle Fuel Additives Give Hope to Fossil Fuel Engines?

Reference

Raja, S. et al., (2022) Energy and exergy analysis and multi-objective optimization of a biodiesel fueled direct ignition engine. Results in Chemistry. 100284. Available at: https://www.sciencedirect.com/science/article/pii/S2211715622000030

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.