In an article published recently in the journal Materials, the coupled influence of graphene oxide (GO) and oxidized multi-walled carbon nanotubes (OMWCNTs) on material characteristics of magnesium oxychloride cement (MOC) phase 5 was investigated.

Study: Co-Doped Magnesium Oxychloride Composites with Unique Flexural Strength for Construction Use. Image Credit: Bannafarsai_Stock/Shutterstock.com

An Introduction to Magnesium Oxychloride Cement

Recent breakthroughs in magnesium oxychloride cement (MOC) research indicate a potential future in the domain of alternate building elements.

MOC is often regarded as an ecologically friendly and efficient building material since it is a non-hydraulic adhesive made from lightly burned magnesia.

The material itself has good flexural and compressive strengths, is fireproof, and has a very quick setting time. Because of its capacity to bind a wide variety of additives, it is possible to improve its qualities with different fillers and to build materials with highly specific characteristics that may be used in many fields of the construction sector.

It is feasible to utilize large amounts of supplementary fillers, such as glass powder, diatomite, wood aggregates, fly ash, lunar regolith simulants, and others, to make an environmentally friendly composite while preserving strength and rigidity.

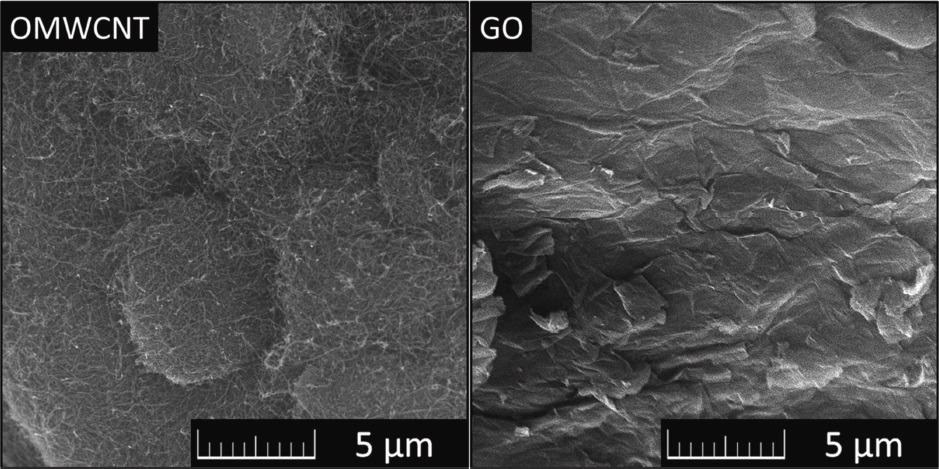

Figure 1. Micrographs of OMWCNTs (left) and GO (right) observed using SEM. © Lauermannová, A.-M., Jankovský, O., et al. (2022).

MOC synthesis is fairly straightforward and based on the molar concentration of the raw ingredients.

MOC phase 5 is the most popular and widely utilized form of this system, which crystallizes as needle-like bristles.

One of the probable explanations for the adhesive's great strength is the interconnecting of these crystalline whiskers. The capacity of MOC to capture carbon dioxide from the environment also influences its characteristics, resulting in the production of magnesium carbonate layers on the exterior of MOC.

The Main Drawback of MOC

MOC's most significant disadvantage is its poor hydrophobicity.

The degradation of MOC in aqueous environments, as well as the reactivity of MOC phases with water to create brucite, have previously been documented.

As a result of this process, the mechanical strength quickly declines, resulting in the leakage of magnesium chloride and the formation of a corrosive medium. As a result, such materials cannot be used in conjunction with steel supports; alternate reinforcements must be investigated.

A viable answer to this challenge may be found in the field of carbonaceous nanomaterials.

Functionalization of Carbon Nanoadditives

The typical employment of carbonaceous nanoparticles in building composites depends on the incorporation of a moderate quantity of the nanomaterial into the substrate while gaining a significant improvement in material characteristics.

This stems from the exceptional characteristics of carbonaceous nanoparticles, which include great compressive strength, good thermal and electrical conductance, and excellent optical qualities.

Graphene and its variants are examples of two-dimensional carbon nanomaterials. Fluorine, sulfur, boron, nitrogen, and other elements may be used to modify graphene.

The 1D category of carbon nanomaterials includes multi-walled carbon nanotubes (MWCNTs) and their derivatives. MWCNTs, like graphene, may be changed to produce a wide range of derivatives with diverse functional groups.

Figure 2. 28-days specimens: MOC-REF, MOC-GO-OMWCNT-0.1, MOC-GO-OMWCNT-0.2 (from left) © Lauermannová, A.-M., Jankovský, O., et al. (2022).

Due to their water-repellant nature, carbon nanotubes and graphene have a poor water distribution, limiting their application in regular building composites.

Because the hydrophobicity of these substances may be changed by functionalization, their distribution in the composite matrix is considerably simpler. The interaction of these nanoscale additives with powerful acids results in the creation of their oxidized counterparts, which may influence the mechanical characteristics of the overall composite.

Important Findings of the Study

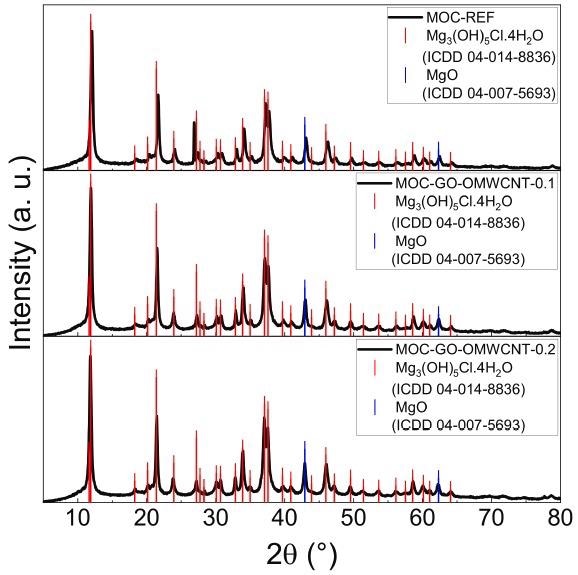

The combined impact of oxidized one-dimensional and two-dimensional carbonaceous nanoadditives on MOC Phase 5 was investigated in this study.

The carbonaceous nanoadditives greatly reduced pores, resulting in an improvement in mechanical characteristics, where the flexural strength rose.

The water transportation and storing qualities of the MOC matrix were substantially reduced with the decrease in volume of pores as a result of their filling and interconnecting with the nanoscale additives; thus, the enhanced hydrophobicity of the MOC framework can be predicted – this effect of the nanodopants is critical for the MOC-based composites.

The heat conduction of the composite was fairly high, owing to the reduced porosity, but also to the adaptation of the heat conductivity of the utilized GO and OMWCNTs, which is usually pretty high.

Figure 3. The XRD patterns of the samples MOC-REF (top), MOC-GO-OMWCNT-0.1 (middle) and MOC-GO-OMWCNT-0.2 (bottom) © Lauermannová, A.-M., Jankovský, O., et al. (2022).

On the basis of these findings, it was determined that the nanoadditives utilized had substantial promise in the formulation and production of sophisticated and versatile MOC-based composites. However, to achieve even larger augmentation of the composite characteristics, the homogeneity and optimal distribution of the nanodopants must be enhanced.

Continue reading: How Can Concrete Properties be Controlled with Nanotechnology?

Reference

Lauermannová, A.-M., Jankovský, O., et al. (2022). Co-Doped Magnesium Oxychloride Composites with Unique Flexural Strength for Construction Use. Materials, 15(2). Available at: https://www.mdpi.com/1996-1944/15/2/604

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.