An article presented in the journal Buildings brings forth new ideas regarding the use of graphene nanoplatelets (GNPs) as a nanomaterial to enhance the effectiveness of high-strength concrete (HSC) constructions at very low temperatures.

Study: Early-Age Performance of Graphene-Nanoplatelet-Modified High-Strength Concrete Cured by Electric Thermal Curing in Severe Cold Regions. Image Credit: bogdanhoda/Shutterstock.com

RPC – A High Strength Concrete

In past decades, reactive powder concrete (RPC) has evolved into a revolutionary cementitious product. Because of its good mechanical qualities, great strength, and exceptional durability, it has piqued the interest of scientists all over the globe.

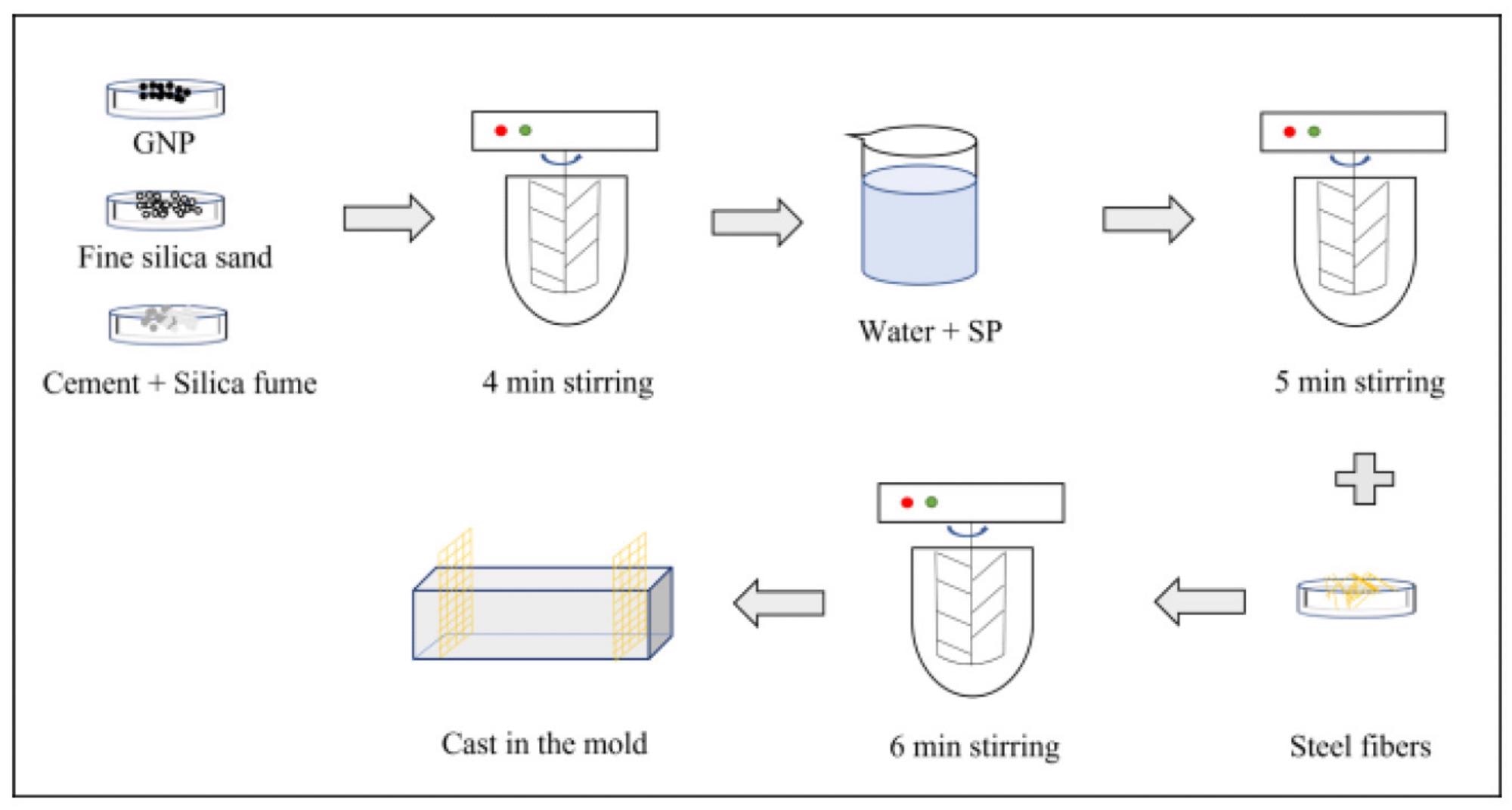

The elevated strength of RPC conforms to the theory of particle density packing; the use of fibers to strengthen the matrix and the inclusion of supplementing cement-based components are also effective in improving RPC characteristics via densification of the composites and hydration stimulation inside the sample.

However, because of the difficult and rigorous curing settings, particularly in cold locations for construction in the winter, where the severe climate is not favorable to the maintenance and functioning of the essential machinery, the use of RPC is mainly limited.

Winter concrete building, in particular, is a critical issue that severely limits the economic and infrastructural growth of many nations. The fundamental issue is that cementitious materials fail to generate strength at very low temperatures owing to frost damage, which occurs quite quickly.

Figure 1. Fabrication process of GNP-HSC samples. © Zhou, Z., Zhang, B., Wang, M., & Wang, W. (2022).

Shortcoming of Traditional Curing Methods

Previously, particular curing techniques such as thermal insulation curing and the warm shed building technique were provided for cementitious materials in a cold climate. The transmission of heat produced around the concrete to the structure, or direct application of heat to the concrete, is the primary premise of these systems.

These approaches have a high potential for preventing frost deterioration to concrete buildings, resulting in greater structural toughness. However, they are heavily reliant on ambient temperatures.

The circumstances also cannot ensure sustained and constant curing conditions for the construction, resulting in uncontrolled strength development in the structure at freezing temperatures. As a result, a unique curing procedure is required for RPC building in cold climates.

Electric Thermal Curing

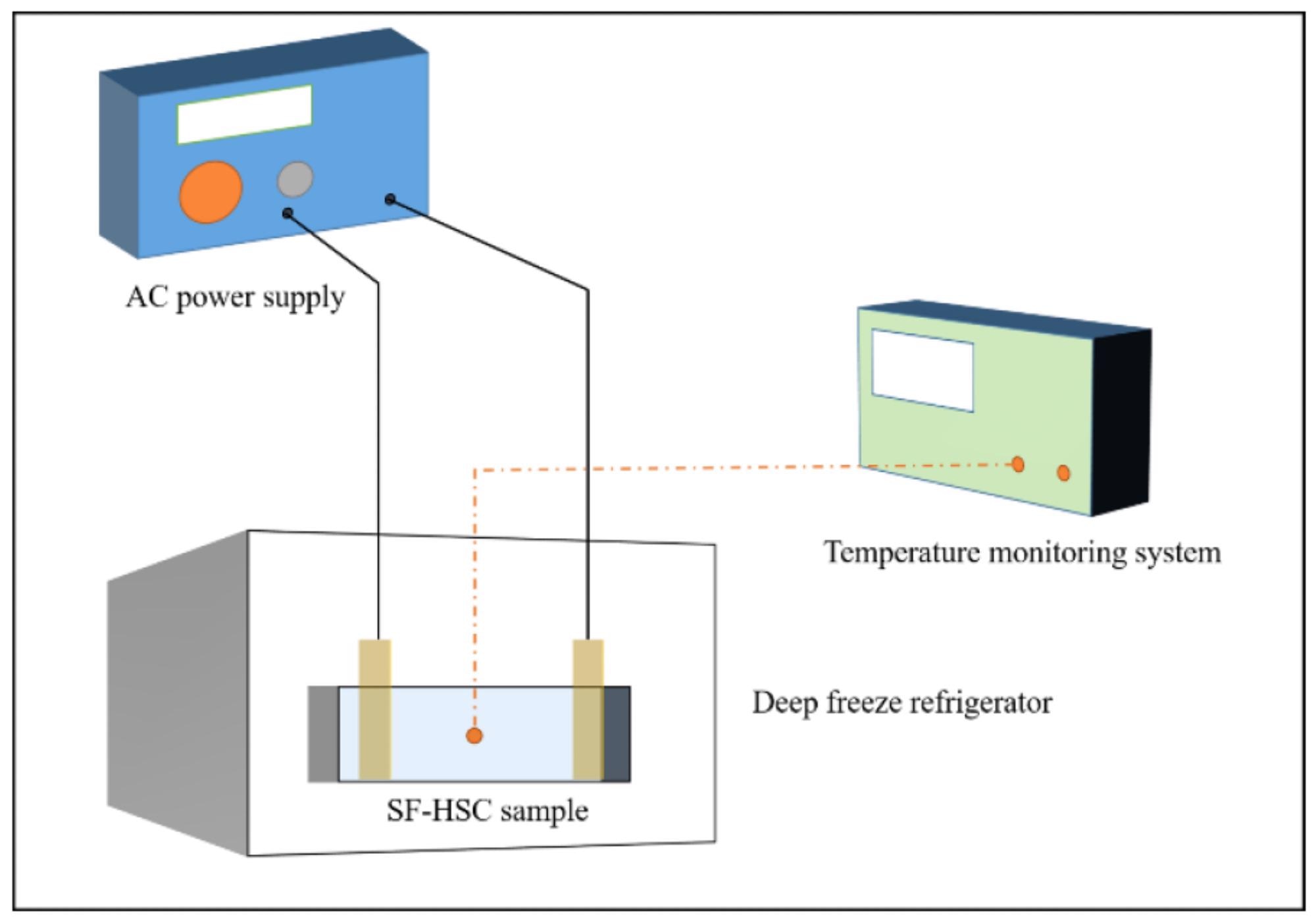

Lately, electric thermal (ET) curing technique has been proposed as a method for achieving the strength creation of cementitious materials under a variety of climatic situations.

ET curing makes use of the heat created by an electric current traveling along with the conducting cementitious materials, and the produced heat is anticipated to supply the necessary temperature to enhance the toughness of RPC at an early age in subzero conditions.

Figure 2. ET curing and temperature monitoring of GNP-HSC. © Zhou, Z., Zhang, B., Wang, M., & Wang, W. (2022).

It is critical for ET-cured samples to have low and consistent electric conductance to guarantee the curing process continues.

Steel fibers have been shown to successfully improve the mechanical characteristics, particularly the strength, of cementitious materials as a typical reinforcing filler with strong electric conductance.

As a result, using steel fibers as a reinforcing filler within ET-cured HSC is a viable option.

Graphene nanoplatelets (GNPs) are a nanosized substance with high electric conductance that may improve the mechanical characteristics of cementitious materials.

Important Findings of the Study and Future Research Direction

GNP was used in this study to significantly enhance the effectiveness of ET-cured HSC specimens at -20°C. The ideal number of steel fibers to include as the major conductive filler was originally calculated mathematically and empirically.

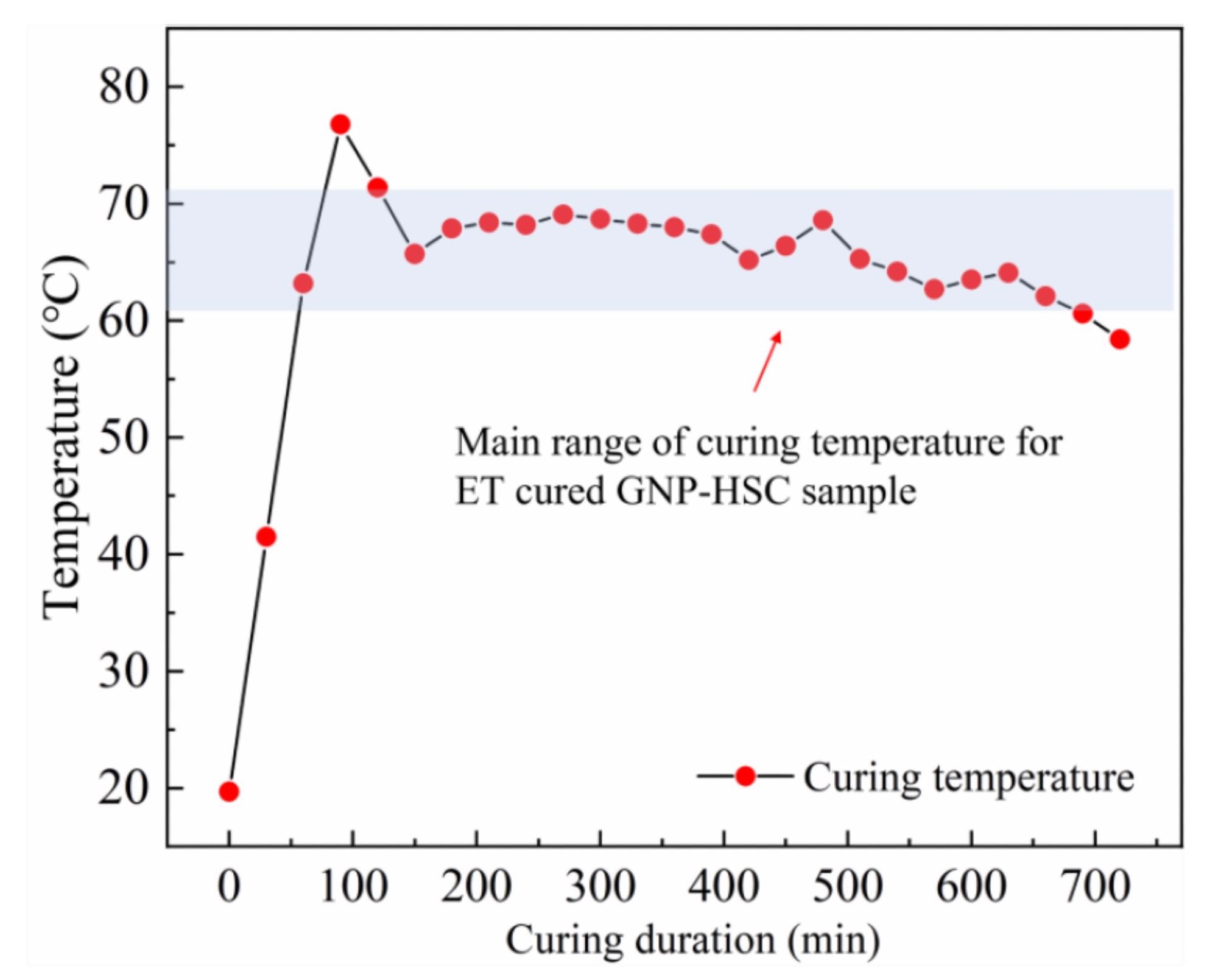

The ET-cured samples showed excellent temperature development uniformity, with the curing temperature remaining in the 60-70°C range.

GNP inclusion might significantly improve the mechanical characteristics of HSC specimens.

The compression strengths of the ET-cured specimens rose with the introduction of GNP. Furthermore, the use of ET curing improves the performance of GNP-HSC specimens: keeping the GNP content same, ET-cured specimens had greater mechanical characteristics than RT-cured specimens.

GNP inclusion may enhance the hydration process in ET-cured GNP-HSC specimens with a greater hydration extent and tighter microstructure, highlighting the superiority of GNP integration for the performance of ET-cured specimens for winter concrete building in cold places.

Figure 3. Temperature development of ET-cured GNP-HSC with 1 vol% GNP addition. © Zhou, Z., Zhang, B., Wang, M., & Wang, W. (2022).

The coupling of ET curing and GNP integration was used in this study to increase the strength of GNP-HSC specimens at -20°C, creating a firm basis for high-strength concrete production in cold climates.

Future research should look at the precise impacts of various conditions of ET curing on the quality of high-strength concrete, such as ambient temperature, curing time, and curing temperature.

Continue reading: High Thermal Effects on Carbon Nanotube-Reinforced Concrete.

Reference

Zhou, Z., Zhang, B., Wang, M., & Wang, W. (2022). Early-Age Performance of Graphene-Nanoplatelet-Modified High-Strength Concrete Cured by Electric Thermal Curing in Severe Cold Regions. Buildings, 12(2). Available at: https://www.mdpi.com/2075-5309/12/2/86

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.