The latest article published in Frontiers in Materials by researchers from Taiwan focuses on a novel CsxWO3/MoS2 nanocomposite via the solvothermal method to investigate hydrogen sensing.

Study: Highly Efficient MoS2/CsxWO3 Nanocomposite Hydrogen Gas Sensors. Image Credit: Alexander Limbach/Shutterstock.com

Negative Effects of High Concentration of Gases

The health of living beings is jeopardized by environments contaminated by elevated levels of gases, which can be extremely hazardous.

When quantities of hydrogen (H2), carbon dioxide (CO2), carbon monoxide (CO), and ammonia (NH3) in the environment surpass permitted limits, they can harm human health.

CO causes pollution, is linked to increased risk of heart disease and can be fatal. As a result, the level of these substances in the atmosphere must be regulated, and proper and effective detection systems must be developed.

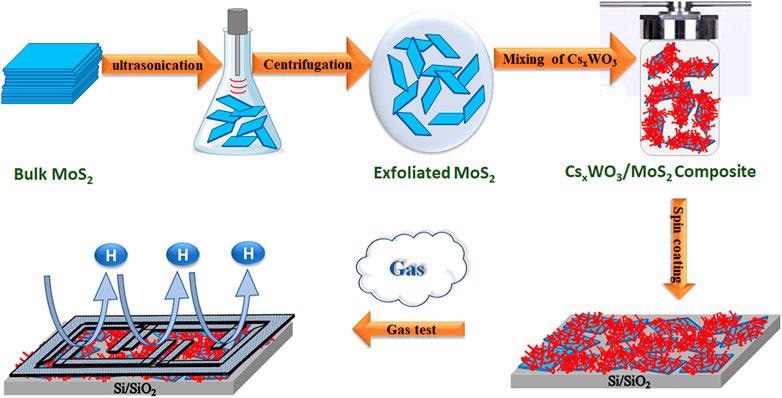

Figure 1. Schematic illustration of the synthesis process of CsxWO3/MoS2-based gas sensor. © Wu, C. M. et al., (2022)

Is Hydrogen Harmful?

Hydrogen is one of the most dangerous gases, and controlling its quantity with appropriate monitoring instruments is critical.

Inhaling hydrogen at low amounts can produce headaches, irritation of the eyes, and seizures.

Asphyxiation can occur if a large quantity of hydrogen is inhaled. It is currently widely employed as an important environmental power source in semiconductor processing, the commercial sector, nuclear power stations, and hydrocarbon extraction.

Hydrogen is a viable contender for novel energy needs in energy plants, automotive mobility, and aircraft. However, because of the inherent hazards of leakage, the containment and controlled delivery of hydrogen are difficult.

As a result, it is imperative to build durable and inexpensive hydrogen sensing devices that are extremely trustworthy for the precise detection of harmful hydrogen gas.

Importance of Tungsten Based Materials

Owing to their nanoscale and unusual physicochemical characteristics, tungsten-based nanomaterials have sparked a deal of attention in recent years.

They are best suited for the fabrication of high-quality detectors because of their great specificity and reliability. Wrought iron trioxide, in particular, has been widely employed in sensors for the detection of dangerous gases such as hydrogen, NH3, nitrogen oxides, and sulfur dioxide.

However, the majority of WO3-based gas sensors operate at high temperatures or have long reaction periods, limiting their practical applications. As a result, it is critical to create tungsten oxide-based gas sensor materials that can overcome these constraints.

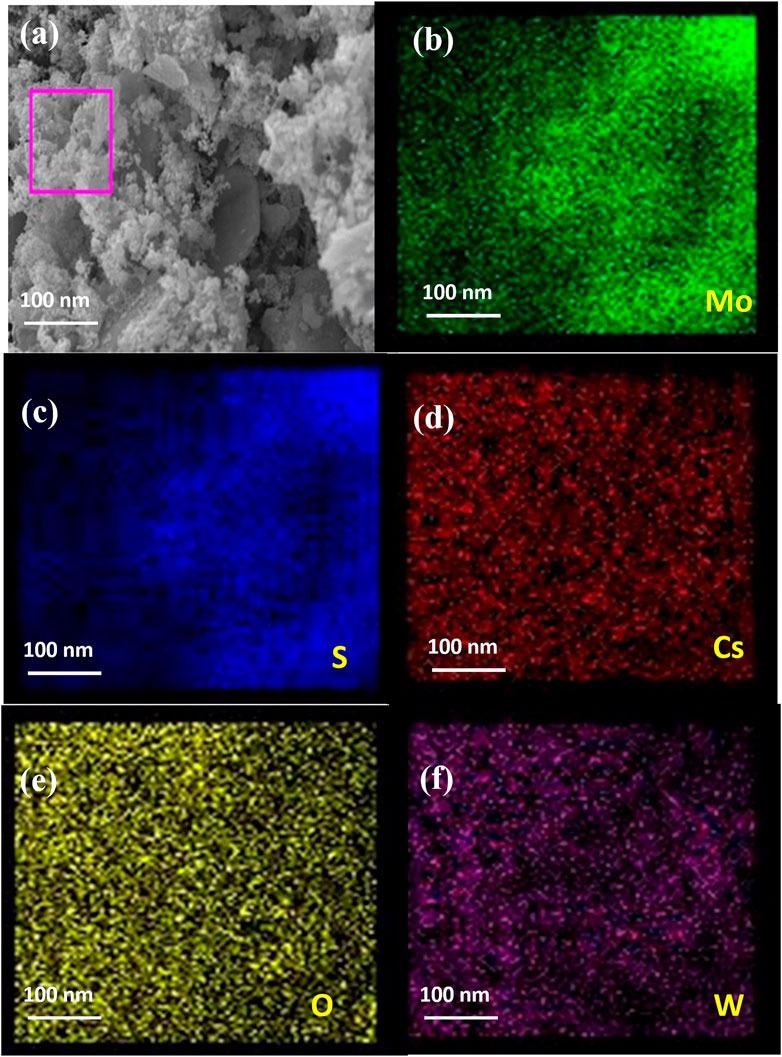

Figure 2. (A) FESEM image and elemental mapping of (B) Mo, (C) S, (D) Cs, (E) O, and (F) W of 15% CsxWO3/MoS2 nanocomposite. © Wu, C. M. et al., (2022)

Effectiveness of Molybdenum Sensors

Molybdenum disulphide (MoS2), on the other hand, is a transition metal dichalcogenide (TMD) that is employed in a spectrum of uses such as photocatalytic activity, detection, sterilization, pollutant deposition, and bilayer extraction.

It has been used in sensor applications such as photocatalytic detectors, sensing applications, hyperglycaemia sensors, optoelectronics, electrochemical devices, and genetic sensors.

At ambient temperature, MoS2 nanoparticles are often preferential toward NH3 gas, limiting their utility as sensing applications.

Although MoS2 is an excellent sensing material, it has certain drawbacks, including limited structural support and permeability.

Combining MoS2 with a specific material is critical for improving device performance.

WO3/MoS2 composites, for example, have been constructed, and the compound has good ammonium and hydrogen sulfide detecting characteristics.

These smart objects, however, only work at degrees over 200 °C. Furthermore, the majority of previously produced hydrogen gas sensors had limited sensor response.

Need for Hydrogen Sensors

For real-world applications, it is critical to design hydrogen gas sensors with high sensitivity, specificity, and durability. As a result, it is critical to produce MoS2 compounds with superior hydrogen sensing capabilities at ambient temperature.

To accomplish this, the researchers used a solvothermal approach to create CsxWO3@MoS2 nanostructures for use in hydrogen gas sensors, making use of CsxWO3's low-temperature detecting characteristics and MoS2's high sensor sensitivity.

What is the Hydrothermal Process?

The hydrothermal approach employs wet-chemical processes to crystallize substances into nanostructures.

It is another common preparation method, particularly for powdery nanostructures. The hydrothermal procedure entailed combining substrates and suitable reagents in a solution to permit the creation of a crystallized nanostructure with the required ratio.

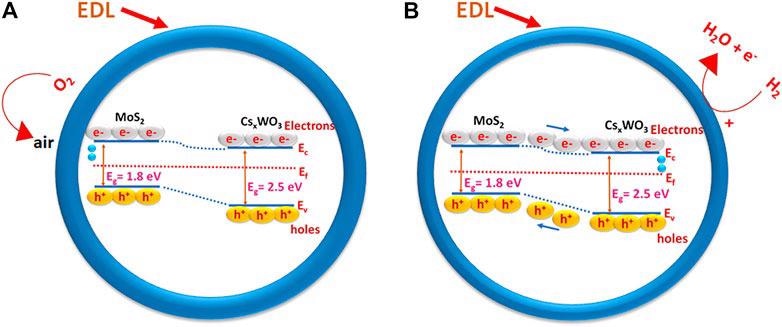

Figure 3. Schematic illustration of CsxWO3/MoS2-based gas sensor (A) in air, and (B) in H2 gas. © Wu, C. M. et al., (2022)

Research Findings

The proposed CsxWO3/MoS2 nanocomposite-based sensor demonstrated excellent hydrogen gas detecting characteristics, with a 51% sensitivity to 500 ppm H2 gas.

It also has high cycle stability. Furthermore, when compared to previously reported H2 gas sensors, the produced 15% CsxWO3/MoS2 nanocomposite displayed a better H2 gas detecting response at ambient temperature. The increased electrical characteristics of the 15% CsxWO3/MoS2 nanocomposite might explain the better sensing performance.

In summary, the innovative study enables the creation of an efficient and appropriate H2 gas sensor at ambient temperature, which will play an essential role in the process of sensing hydrogen gas in the atmosphere and is a suitable candidate for commercial use in the monitoring of hydrogen gas.

Reference

Wu, C. M. et al., (2022) Highly Efficient MoS2/CsxWO3 Nanocomposite Hydrogen Gas Sensors. Frontiers in Materials. Available at: https://www.frontiersin.org/articles/10.3389/fmats.2022.831725/full

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.