A study published in the journal ACS Applied Materials & Interfaces proposes a high porosity anodic alumina/aluminum flake powder material for optical and infrared camouflage, influenced by the light-absorbing phenomenon of butterfly wing scales.

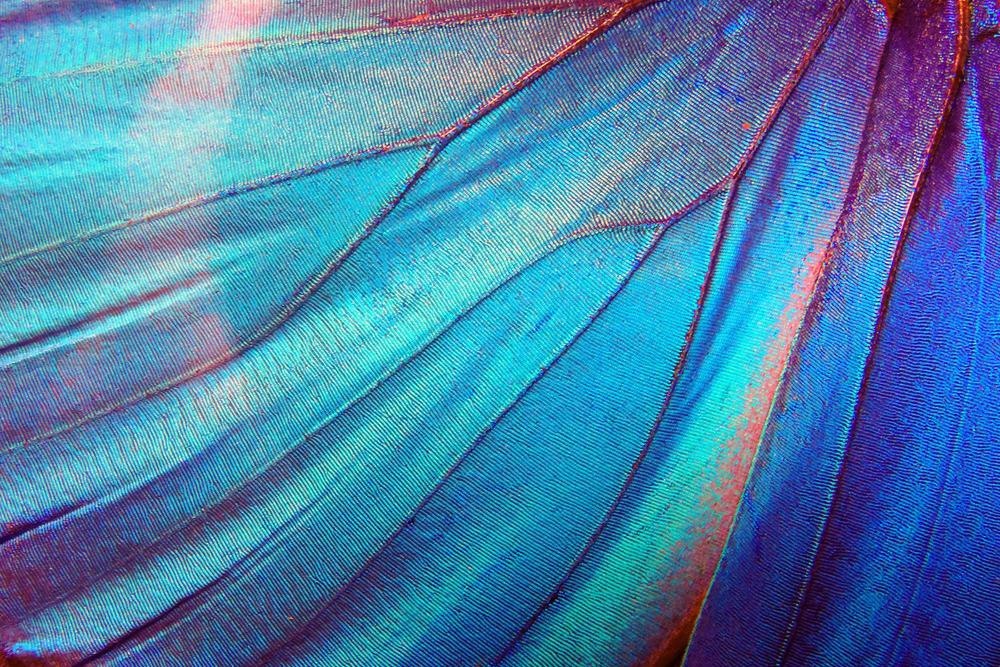

Study: Bioinspired Porous Anodic Alumina/Aluminum Flake Powder for Multiband Compatible Low Detectability. Image Credit: KRIACHKO OLEKSII/Shutterstock.com

Camouflage Technology

By displaying fake information, camouflage technologies are able to hide information about an object to deceive attackers.

Here, the differences in radiation or scattering between the target and the background are reduced across visible (VIS), infrared (IR), and even microwave spectra.

Because guiding systems often employ multi-spectrum frequencies to locate and follow targets, visible-infrared (VISIR) compliant camouflage has gained increased scientific attention.

Challenges in Achieving VIS-IR Camouflage

Covering or coating low emissivity substances on objects is a straightforward, integrated way for realizing infrared camouflage based on the Stefan Boltzmann equation.

The most prevalent reduced-emissivity substances are high conductivity metals with strong spectral reflection over the entire infrared spectrum.

Metals with strong reflectivity in the visible spectrum, on the other hand, are readily detected.

As a result, there are issues with multi-spectrum VIS-IR compliant camouflage since the spectrum requirements for various bands differ.

A number of studies on photon crystals (PCs) have been published for VIS-IR compliant camouflage.

The spectrum emissivity of the PC is less than 0.5 at both IR atmospheric regions. Furthermore, PCs with a particular shape display multiple colors for improved VIS camouflage.

However, the production of PCs is hampered by their high thickness and extra bulk, which results in a higher price, a complex manufacturing method, and inadequate mechanical stability.

Most notably, painting PCs onto the surface of the armament to achieve realistic camouflage is challenging. Moreover, these manufactured regular structures display angular alignment based on models in prior research, which is detrimental to the omnidirectional detectability.

Inspiration for the Study

In this study, a microscale powder anode oxidation (micro-PAO) method was developed to manufacture porous anodic alumina (PAA)/aluminum flake powder (AFP), that accomplishes the VIS-IR compliant camouflage and offers improved mechanical integrity as a covering filler.

The architecture is based on butterflies and moths, where a large number of scales with a complex structure at the nanoscale coat the lepidopterans’ wing surfaces.

These natural structures have outstanding optical capabilities in terms of structural color management, photon absorptivity, and optical camouflage. Furthermore, the microscale nanoporous architectures of lepidopterans’ wing scales demonstrate the traits of short range disorder and long range order.

This avoids blind spots and enhances omnidirectional absorbance of incident light.

Key Findings of the Research

A visible-infrared multi-spectrum compliant camouflage substance was created in this work using a revolutionary microscale powder anode oxidation (micro-PAO) process.

Regardless of the fact that the traditional electroplating procedure is mostly employed in macroscale settings, this method has expanded its applicability to microscale settings as well.

In this study, a nanoscale porous anode alumina (PAA) layer was generated on-site on the surface of microscale aluminum flake powder (AFP) to create PAA/AFP composites for multi-spectrum camouflage purposes.

The micro-PAO development method is explored, and the entire procedure is clarified using a multilevel nanoscale pore oxygen-bubble development model that differs from the standard AAO development model.

The technique is useful for guiding the parameter adjustment in the research to efficiently produce multi-spectrum camouflage substances with functional structures.

These surface PAA layers with disorganized nanoscale pores give visible spectrum camouflage with remarkably low orientation dependency. Furthermore, the base AFP layer with a large radius-to-thickness proportion offers dual-spectrum IR camouflage.

By developing and integrating PAA/AFP with an IR transparent adhesive such as ethylene propylene diene monomer (EPDM) for multi-spectrum camouflage coverings, elastic wearable applications and sophisticated unconventional devices may be produced.

Reference

Fu, S., Zhang, W., et al. (2022). Bioinspired Porous Anodic Alumina/Aluminum Flake Powder for Multiband Compatible Low Detectability. ACS Applied Materials & Interfaces. Available at: https://pubs.acs.org/doi/10.1021/acsami.1c23879

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.