The physical, thermodynamic, and thermal properties of extruded earth-based composites reinforced with 0.1 percent, 0.3 percent, and 0.5 percent wt. of nanofibrillated cellulose was investigated in a recent paper published in the journal Case Studies in Construction Materials.

Study: Potential of raffia nanofibrillated cellulose as a reinforcement in extruded earth-based materials. Image Credit: Bannafarsai_Stock/Shutterstock.com

Because of its distinctive features, nanosized cellulose synthesis and use as a support in building materials have attracted a lot of interest.

The findings suggest that mechanical nanofibrillation enhances the thermostability of the fiber. Their incorporation into an earthen matrix improves the modulus of elasticity and specific energy while not affecting the water retention or heat capacity of the composites.

Applications of Cellulose in Construction Industry

Cracks, irrespective of their thermodynamic, structural, or physical features, are considered to be a primary entrance site for hostile reactive ions or moisture, which infiltrate into cement and earth-based structures, deteriorating their characteristics and endurance.

Incorporating cellulose fiber into an industrial composite has been shown in many tests to dramatically reduce the creation and propagation of fractures in the material. Furthermore, the low price, global availability, and renewability of lignocellulosic materials fiber derived from materials such as bamboo, raffia tree, sweet potato exfoliates, and fruit peels have compelled researchers to consider using it as the main reinforcing component in a concrete mixture.

The chemical modification offers cellulose fibers excellent strength and rigidity, shrinks the gap between fibers, and encourages a high surface-to-volume ratio, making them more effective in crack suppression than conventional fibers.

Research has indicated that removing hemicelluloses remnants during the pulping process of natural materials increases the thermal degradation of cellulose by boosting the fiber's thermostability.

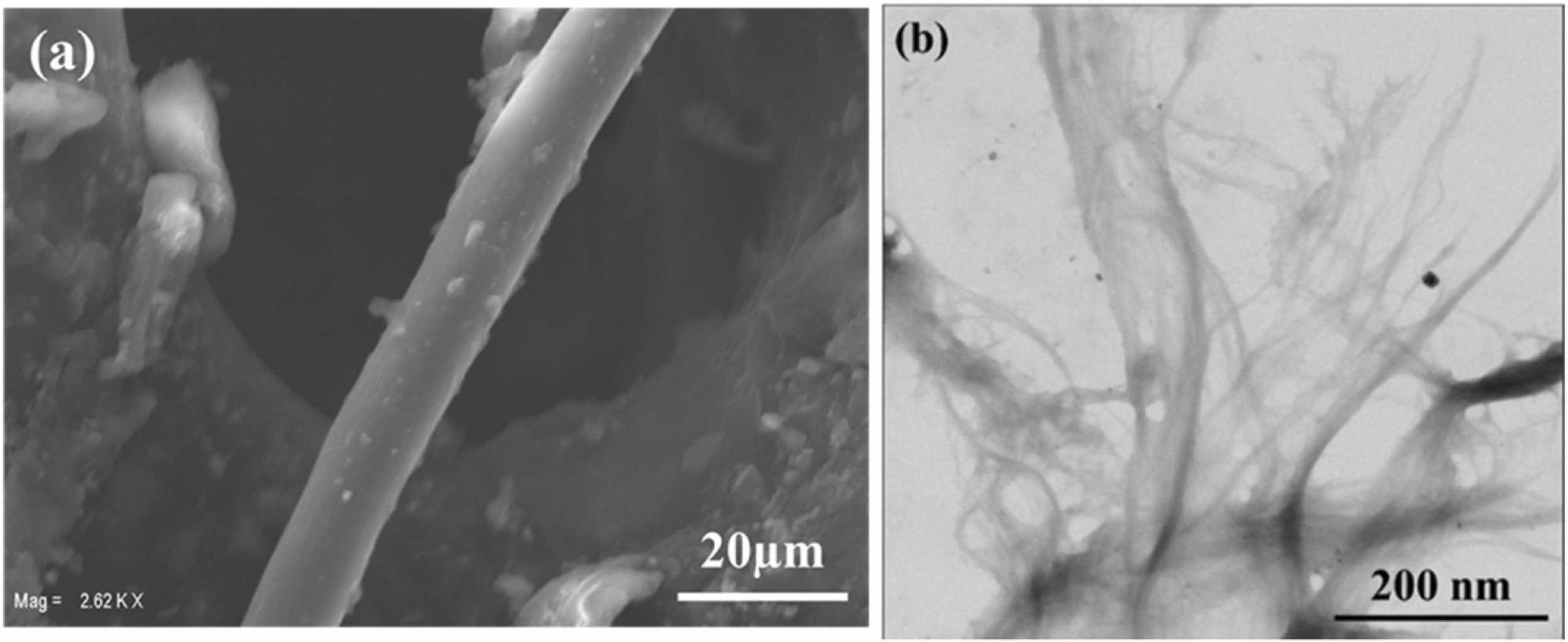

Figure 1. (a) SEM micrographs of raffia organosolv pulp and (b) TEM micrographs of raffia nanofibrillated cellulose. © Stanislas, T. et al. (2022)

Nano-scale Presence of Fiber in Cementitious Materials

The inclusion of nano-scale fibers in cementitious composites generates a crossing process of the reinforcing materials in the nano-sized gaps of the concrete substructure, improving the composite's modulus of elasticity.

In prior work, cellulose nanofiber derived from wheat bran was used to adjust the thermomechanical characteristics of concrete mixtures at concentrations of 0.5 percent, 1 percent, 1.5 percent, and 10 percent.

The addition of 0.5 percent nanofiber considerably increases the tensile strength of concrete, followed by a progressive decline in compressive strength with nanofiber incorporation.

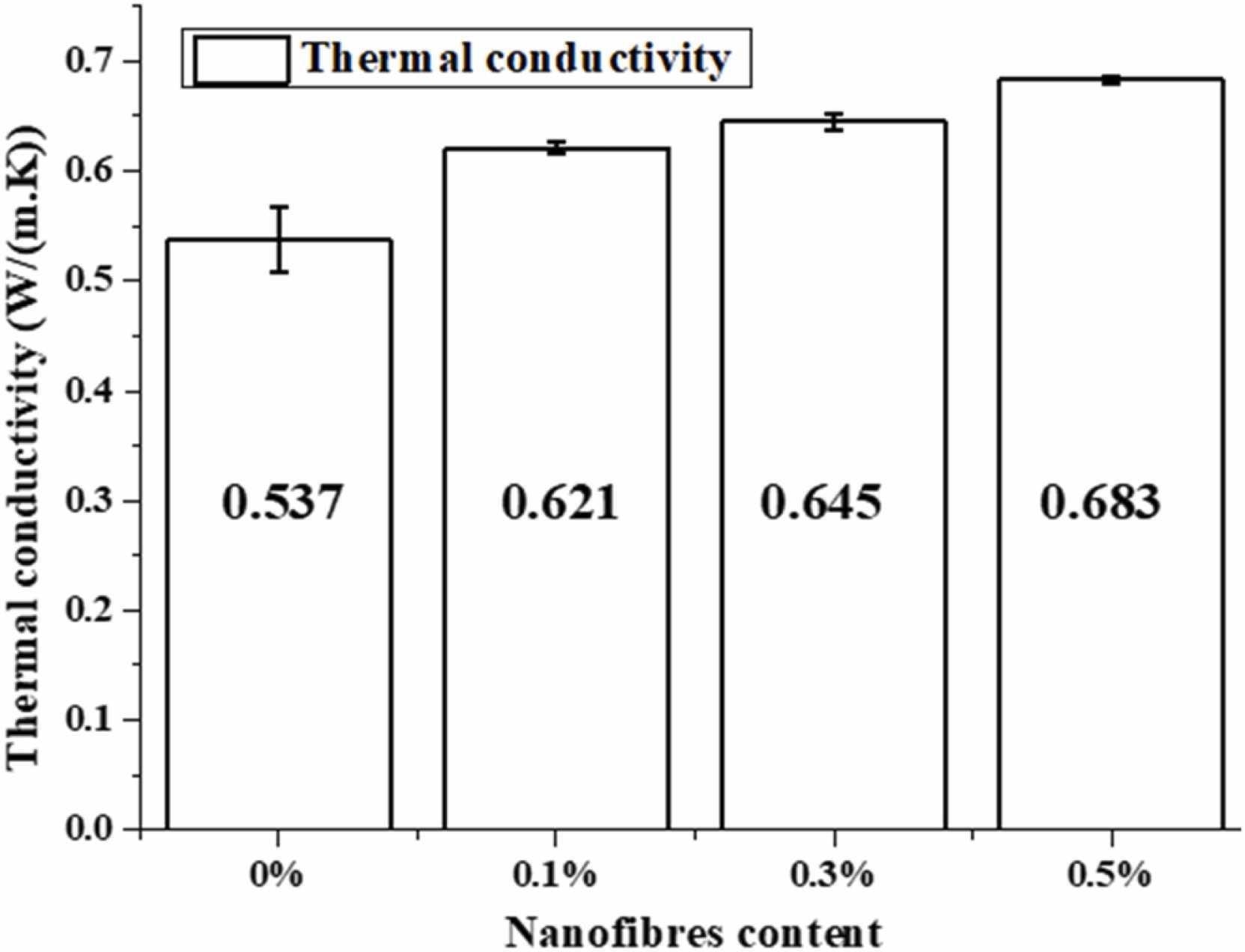

With the addition of nanofibrillated cellulose, the heat capacity steadily rises. To lower heat capacity, density, and increase permeability, hardness, stiffness, and compressive strength of composite materials, a low proportion of nanofibers in the substrate is required.

Even though research on concrete mixtures supplemented with cellulose fibers has discovered improved sensitivity, no studies on the impact of raffia cellulose nanofiber on the efficiency of soil mixtures have been conducted.

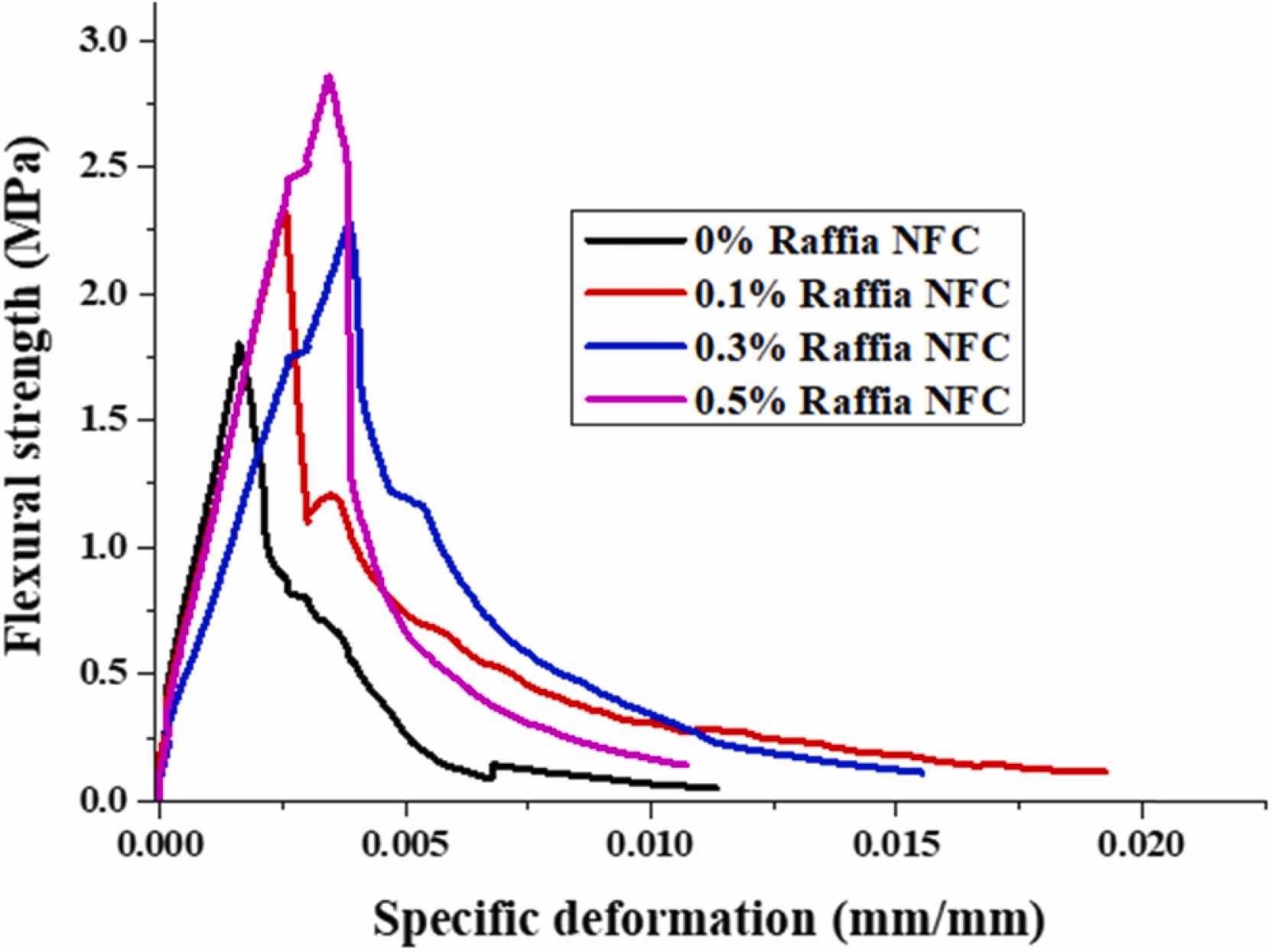

Figure 2. Typical stress-strain curves during four-point bending test of the earth-based materials containing 0%, 0.1%, 0.3% and 0.5%wt. of raffia nanofibers. © Stanislas, T. et al. (2022)

Influence of Raffia Bamboo Nanofiber on Cement

Raffia (Raffia bamboo) provides a significant chance for low-income workers in tropical places to get economical construction materials since it is a plentiful, fast-growing, and cheap resource.

Raffia plants have been the subject of many studies to assess their insulating qualities, physical-mechanical efficiency, and building architectural reinforcement effectiveness.

In this study, the researchers tested how Raphia vinifera nanofibers affected the concentration, permeability, drying shrinkage, modulus of elasticity, and heat capacity of cement-stabilized earth-based composite.

Research Findings and Prospects

Due to the removal of hemicelluloses during the purification process, the findings showed that filtration and nanofibrillation increased the thermostability of cellulosic fibers. Furthermore, this research found that including nanofiber into earth-based composites increases density while decreasing perceived gap size, which might be due to the increased moisture content of the substrate and the aqueous character of the nanofiber.

The power density of the composite rises from 0 to 0.1 percent wt of nanofiber and then drops abruptly with the inclusion of more nanofiber, but the composite's fracture toughness rises with the introduction of nanofibers.

Figure 3. Influence of nanofibre content on the thermal conductivity of earth-based composite. © Stanislas, T. et al. (2022)

In comparison to the composites reinforced with 0.3 percent cellulose nanofiber, the microstructural examination revealed that the architecture of the unstrengthened material is not well packed and has numerous fractures and holes.

Incorporating a little quantity of raffia nanofibrillated cellulose into earth-based materials achieves an adequate combination of heat capacity, rigidity, and durability for the manufacture of environmentally benign and low-cost housing components.

Reference

Stanislas, T. et al. (2022). Potential of raffia nanofibrillated cellulose as a reinforcement in extruded earth-based materials. Case Studies in Construction Materials. Available at: https://www.sciencedirect.com/science/article/pii/S2214509522000584

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.