A group of researchers recently published a paper in the journal ACS Nano that demonstrated the effectiveness of two-dimensional (2D) transition metal carbides (MXenes) as electrodes in large-area electronic devices, specifically as rear electrodes in silicon solar cells.

Study: Scaled Deposition of Ti3C2Tx MXene on Complex Surfaces: Application Assessment as Rear Electrodes for Silicon Heterojunction Solar Cells. Image Credit: Dave Weaver/Shutterstock.com

Background

Currently, crystalline silicon (c-Si)-based solar cells dominate the photovoltaic (PV) solar industry by accounting for over 95% share.

Among the c-Si-based solar cells, silicon heterojunctions (SHJs) displayed considerable success as their power conversion efficiency (PCE) values exceeded 25% in a two-side contacted layout.

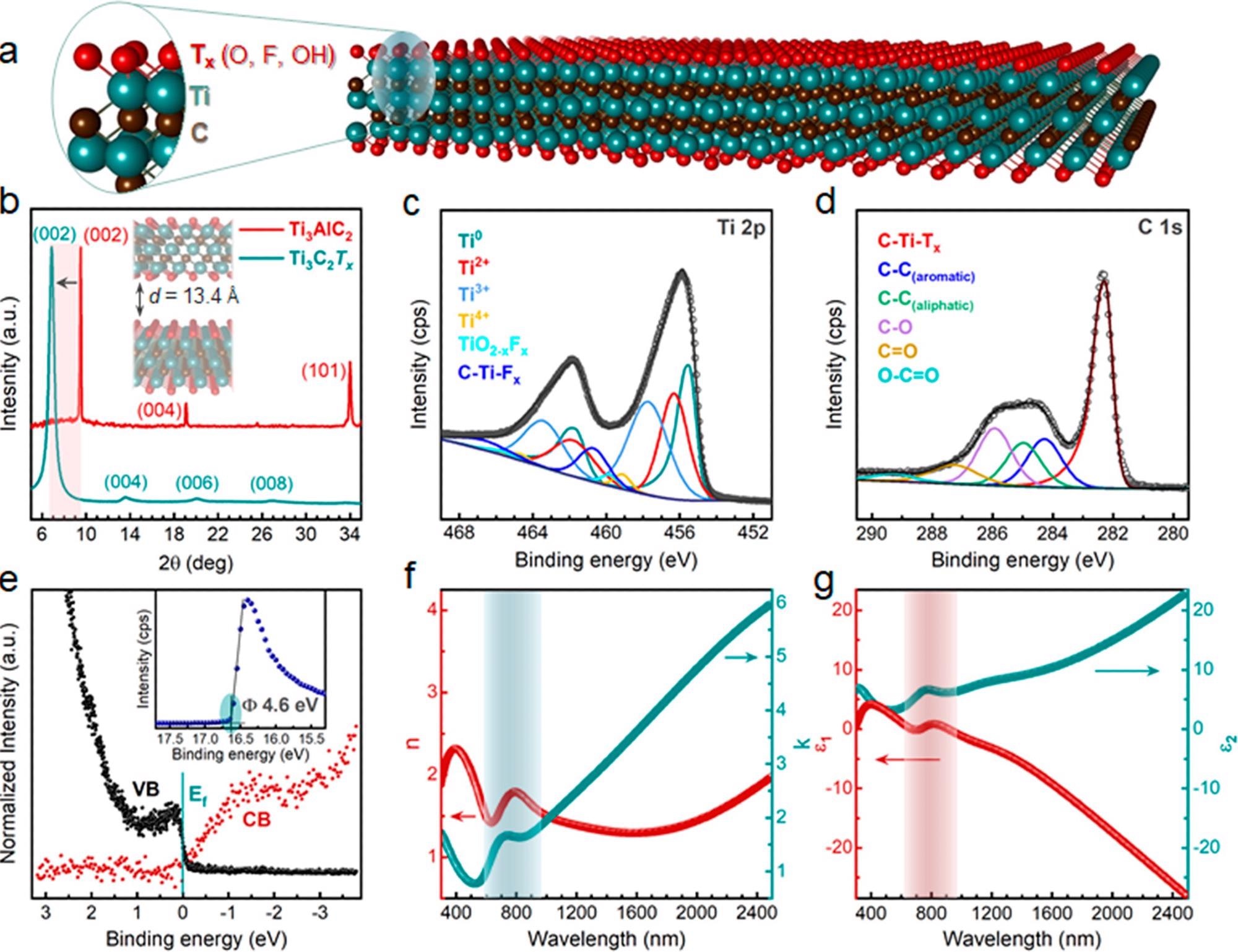

Figure 1. (a) Schematic illustration of a Ti3C2Tx monolayer, where Tx denotes the surface-terminated functional groups (−O, – OH, −F). (b) XRD spectra (vertically displaced for clarity) of Ti3AlC2 MAX (top) and Ti3C2Tx MXene (bottom). (c and d) High-resolution XPS spectra of Ti 2p and C 1s core levels, respectively. (e) Density of states (DOS) at the Fermi level (Ef) in occupied (UPS, black) and unoccupied (IPES, red) spectra of Ti3C2Tx. Inset: UPS secondary electron cutoff (SECO) spectrum along with the extrapolated work function (i.e., 4.6 eV) of Ti3C2Tx. (f and g) Optical constants (n, k) and complex permittivity (ε1, ε2) of a ca. 57-nm-thick Ti3C2Tx spray-coated film, respectively. The shaded regions denote the onset of the characteristic plasmonic absorption of Ti3C2Tx. © Razzaq, A., Kang, J., Sansoni, S. et al. (2022)

Monofacial SHJ solar cells often utilize full-area metallization in which a 200−300 nm thick silver (Ag) film is sputtered at the rear side of the device and deposited on transparent conductive oxides (TCOs).

Although Ag rear contacts have several benefits such as efficient charge collection with a high fill factor, price volatility, and scarcity of Ag and large-scale deployment of PV cells can adversely impact the production of c-Si solar cells in the long term.

Against this backdrop, 2D layered materials emerged as an attractive alternative to traditional metal electrodes owing to their long-term stabilities, low cost, and high conductivity.

Among the 2D materials, the family of MXenes has gained prominence owing to their wide range of tunable and optoelectronic properties.

Titanium carbide (Ti3C2Tx) is considered more suitable as an electrode for solar cells compared to other MXenes due to its metal-like conductivity.

In this study, researchers investigated the applicability of Ti3C2Tx MXene films as rear electrodes for monofacial SHJ solar cells.

The Study

Ti3C2Tx MXene flake suspensions were prepared by selectively etching the aluminum (Al) layer from the parent titanium aluminum carbide (Ti3AlC2).

1 g of Ti3AlC2 powder with less than 40 μm particle size was added to a 10 mL of etching bath containing deionized (DI) water, hydrochloric acid (HCl), and hydrofluoric acid (HF) at a ratio of 3:6:3, and then the mixture was stirred for 15 h at 40oC.

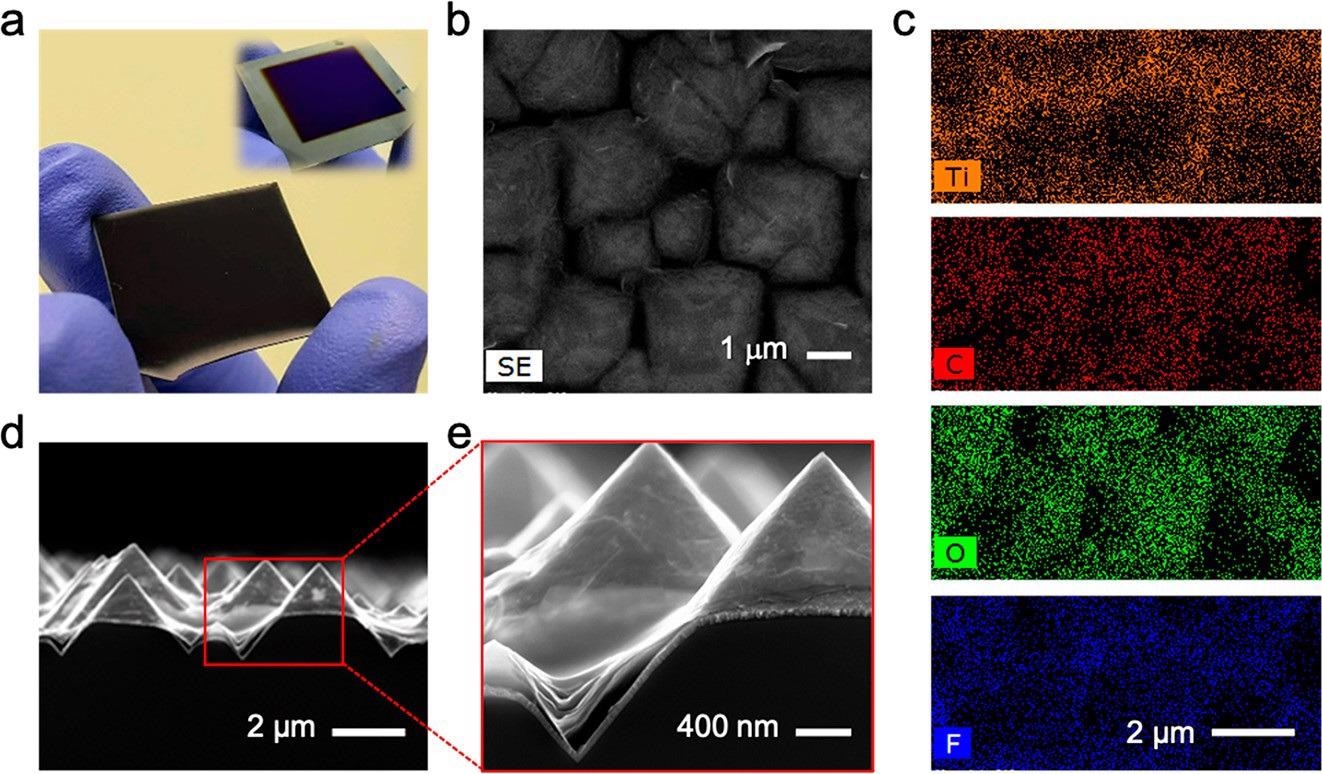

Figure 2. (a) Rear side of a Ti3C2Tx-contacted SHJ solar cell (4.2 cm2 in area). Inset: Rear side of the SHJ device before spraying Ti3C2Tx. (b) Top-view secondary electron (SE) SEM micrograph of a Ti3C2Tx film sprayed on the textured interface of an SHJ cell and (c) corresponding EDS elemental maps showing the homogeneity of Ti (orange), C (red), O (green), and F (blue) across the textured surface. (d and e) Cross-section SEM micrographs of a 57-nm-thick spray-coated Ti3C2Tx rear contact, showing the uniform surface coverage of the MXene flakes on the textured surface of the SHJ cell. © Razzaq, A., Kang, J., Sansoni, S. et al. (2022)

Subsequently, the resultant exfoliated MXene flake suspensions were subjected to multiple centrifugation rounds to achieve a pH value between 6 and 7.

For delamination, lithium chloride (LiCl) was used to intercalate the exfoliated MXene flakes, and then the LiCl-intercalated MXene suspensions were again subjected to another round of decantation until a pH value of 6-7 was attained.

By adjusting the centrifugation speed and time, the size of the MXene flakes was controlled.

Supernatant delaminated Ti3C2Tx flake solutions with an average size of 2 μm were obtained after over 20 min of centrifugation at a speed of 1000 rpm.

Eventually, the synthesized MXene suspensions were stored at 3oC to reduce their rate of oxidation in water.

A fully automated Sono-Tek Corporation coating system was employed to implement ultrasonic spray pyrolysis in order to spray-coat the Ti3C2Tx flakes on the surfaces of both indium tin oxide (ITO)-coated rear side of the SHJ cells and glass substrates.

The substrate temperature was kept at 180oC during the spray coating process, while the solution feed rate was maintained at 2 mL/min.

A powder X-ray diffractometer was utilized to conduct the X-ray diffraction (XRD) analysis, while a Carl Zeiss AURIGA CrossBeam workstation with a Quantax EDS spectrometer and a focused ion beam (FIB) column was employed to perform energy-dispersive X-ray spectroscopy (EDS) and scanning electron microscopy (SEM) analyses.

Large-area SHJ solar cells were fabricated on a pseudosquare CZ double-side textured wafer, while small-area SHJ solar cells were fabricated on float-zone double-side textured four-inch wafers.

A Wavelabs Sinus 220 LED-based solar simulator with an AM 1.5G irradiance spectrum was utilized to perform the current-voltage (J-V) measurements at 25oC. The stability of the Ti3C2Tx-contacted device performance was monitored after 20 months of ambient air conditions.

Observations

Large and freestanding Ti3C2Tx flakes with over 2 μm in size were synthesized successfully. High-quality MXene rear contacts with better uniformity along the pyramidal texture surface were obtained for SHJ solar cells.

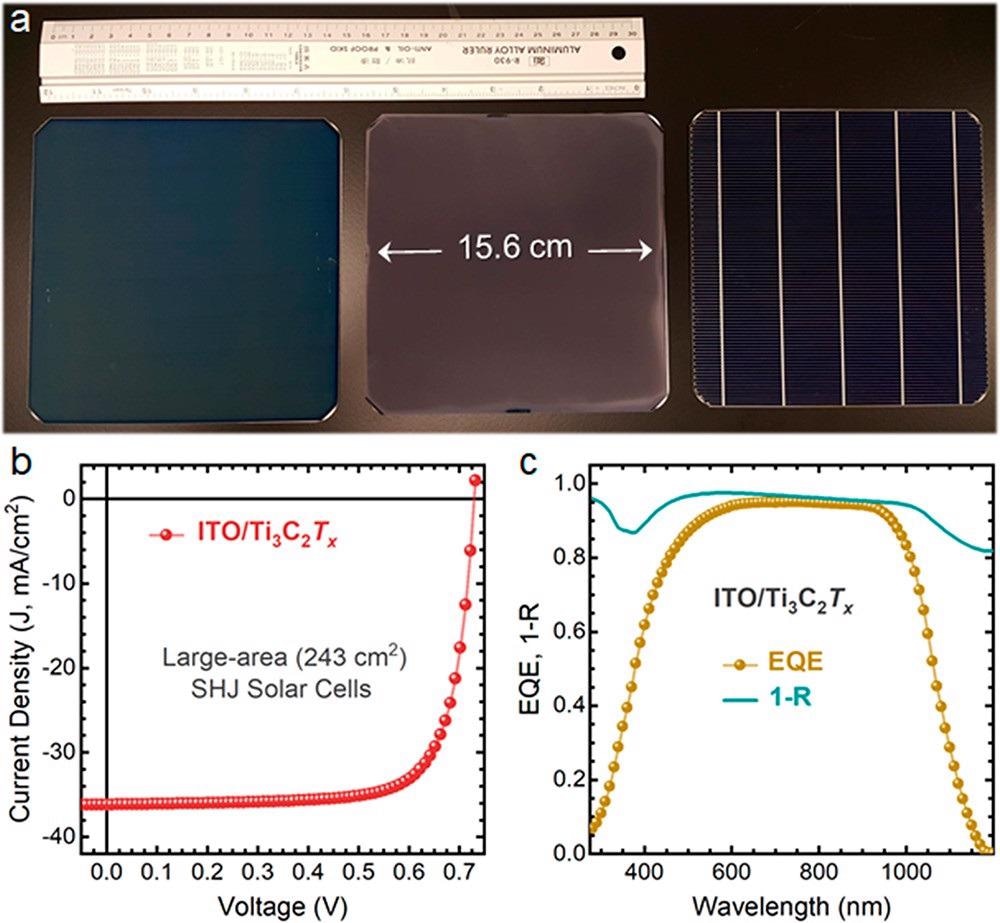

Figure 3. (a) Photograph of the two sides of a large-area (6-in.) SHJ solar cell before and after spraying (140 cycles) the Ti3C2Tx MXene (200 nm thick) on the rear side (left and middle, respectively). The SHJ cells are juxtaposed with a 30-cm-long ruler as a reference scale. (b) J–V characteristics of the Ti3C2Tx-contacted SHJ solar cell (243 cm2 in area). (c) Corresponding EQE and 1-R spectra of the same solar cell in (b). © Razzaq, A., Kang, J., Sansoni, S. et al. (2022)

More than 20% PCE was achieved by the Ti3C2Tx-contacted devices with 4.2 cm2 in area and 200 nm in thickness, with prolonged stability for over 20 months and good reproducibility.

The PCE measured in the MXene-contacted devices was approximately 1% less than that of Ag-contacted devices. However, after upscaling, the PCE attained by the Ti3C2Tx-based SHJ cells with an area of 243 cm2 industry size wafers was 20%, which is almost similar to the Ag-contacted SHJ cells. This observation demonstrated the potential of MXenes as scalable electrode materials.

The series resistance displayed by the 243 cm2 MXene-based SHJs was low, which indicates the suitability of using nonclassical metallic contacts for large-area devices.

Significance of the Study

Taken together, the findings of this study demonstrated that upscaled MXene rear contacts can effectively replace the Ag rear contacts in the monofacial SHJ solar cells, which is an appealing prospect if MXene suspensions can be manufactured at a low cost and large scale.

However, most studies must be performed to examine the stability of these contacts and verify the solderability of external contacts to the MXene electrodes before performing any electronic device integration.

Reference

Razzaq, A., Kang, J., Sansoni, S. et al. (2022) Scaled Deposition of Ti3C2Tx MXene on Complex Surfaces: Application Assessment as Rear Electrodes for Silicon Heterojunction Solar Cells. ACS Nano https://pubs.acs.org/doi/10.1021/acsnano.1c08871

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.