A metal-organic framework is composed of metal ions and organic surrounding molecules forming a complex structure useful for synthesizing nanoporous carbons (NPC), as explained in an article published in Accounts of Materials Research.

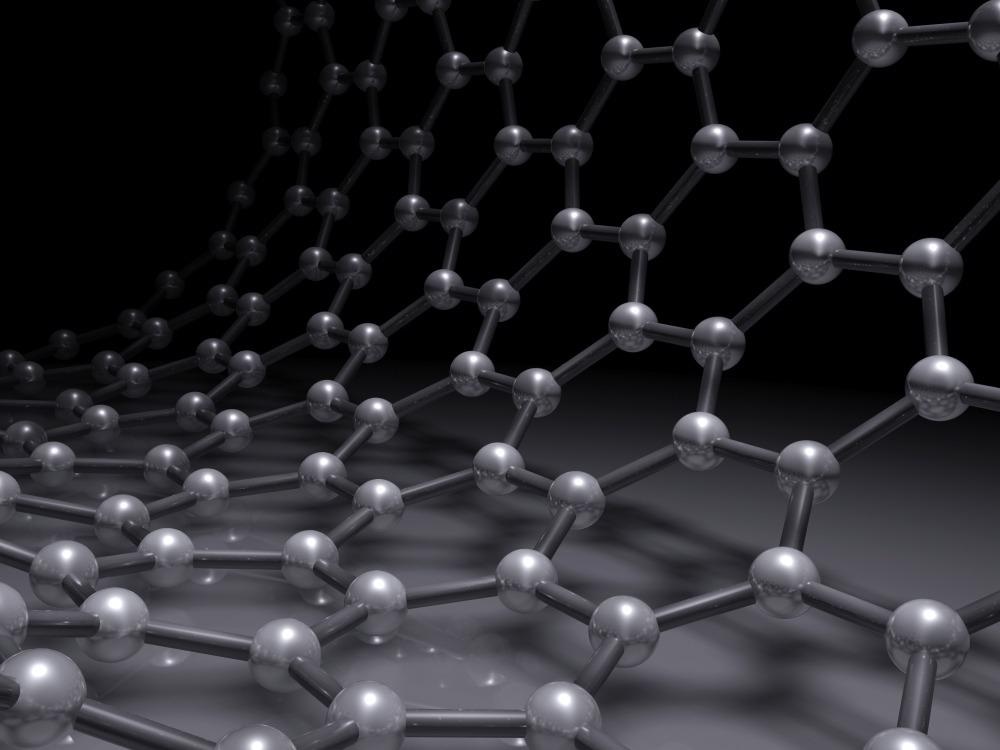

Study: Metal–Organic Frameworks: A Robust Platform for Creating Nanoarchitectured Carbon Materials. Image Credit: Evannovostro/Shutterstock.com

Are Nanoporous Carbons Advantageous?

Owing to its fascinating physicochemical features, nanoporous carbon composite materials have been extensively used for a broad array of applications.

The widespread use of these materials is due to the integration of a homogeneously developed porous matrix (micropores as well as mesopores) and the inclusion of heterocyclic constituents such as oxygen, nitrogen, and sulfur. They have high electric conductance, outstanding durability, vast surface regions, and are environmentally friendly, therefore they are gaining popularity for power storage, pollution control, chemical processing, and other purposes.

Historically, NPCs are synthesized by pyrolyzing an organic substrate and then activating it using a physiochemical technique. It is extremely preferred to look for suitable antecedents and establish easy methods for producing NPCs.

What is Metal-Organic Framework (MOF)?

The metal-organic substrate which undergoes self-assembling utilizing metallic ions or complexes and organic ligands have piqued the interest of researchers due to their highly organized porous frameworks, customized components, and substantial active sites.

MOFs have structural variety due to the huge number of permutations of inorganic metal centers and organic linkers, making them a suitable candidate for developing varied materials for different uses.

Owing to their advantageous features, they are utilized for the synthesis of NPCs of various topologies focused on different industries. MOFs produced using older techniques, such as the solvothermal process, are typically fine granules.

Carbonization transforms these highly structured and crystalline nanostructures into NPCs while conserving the morphology of the source MOFs.

Role of MOF in 0-Dimensional Nano Frameworks

Nano polyhedral MOFs, being one of the most frequent topologies, have been widely employed as prototypes or antecedents to manufacture 0D NPCs due to various benefits, including simplicity of manufacturing, variety, speed, and cost-effectiveness.

However, due to the membrane pore property of the parent MOFs, the majority of the daughter NPCs have a micropore-dominant structure, which dramatically reduces the reaction mechanism. Single MOFs' low capability severely limits their applicability.

Along with polyhedral MOFS, hollow structures have also been the center of focus. Hollow NPCs have several benefits over nano polyhedral nanotubes, including lower densities, maximum loading limits, and small diffusion pathways.

To generate hollow NPCs, the traditional synthesizing approach, the Kirkendall effect, and Ostwald ripening have all been frequently employed.

One Dimensional Nano-Structural Synthesis

One-dimensional nanostructures, such as nanotube morphology and nanofibers, are elastic and self-contained, with minimal electron transport routes and excellent stability.

Since the geometries of the primary MOFs may be retained by the resultant NPCs, the most apparent way to construct 1D NPCs is to employ the same-shaped MOFs as predecessors. Most commonly, electrospinning methods are implemented for the uninterrupted fabrication of such materials.

Is MOF also Advantageous for 2-D and 3-D Nano-Structures?

As a result of their distinctive designs and rich photovoltaic capabilities, two-dimensional NPCs such as nanoflakes, nanofiber sheets, and graphene nano-mesh (GM) offer promising futures.

MOF-derived 2D NPCs have created either the simple direct carbonation of 2D MOFs or their mixtures or through the hydrothermal treatment of carbon nanorods.

The density of the layering is the most important aspect affecting the quality of 2D NPCs. As a novel idea in 2D NPCs, GM is also known as permeable graphite with single- or few-layer carbon nanosheets possessing intrinsic efficient mass transfer characteristics. However, producing GM on an industrial wide-scale remains difficult.

MOF-derived 3D nanostructures have distinct properties when contrasted to their lower-dimensional equivalents, such as excellent tensile durability, adaptability, and reduced component operational costs.

Configurable techniques have been used to create three-dimensional nanostructures such as carbon aerogels, nanoarrays, and gradient monoliths. Common synthesis methods, including freeze-drying, chemical vapor deposition (CVD), and direct pressing, are widely used.

Because of their excellent physical features, carbon aerogels (CAs) with 3D-linked networks are intriguing for novel technologies. Due to the obvious intricacy of numerous synthesis methods, the fabrication of polymer-derived CAs remains a tremendous problem.

It should be noted that the prices of MOF-derived NPCs are significant in comparison to activated charcoal. As a result, less costly synthesis techniques and high-value-added applications, such as clinical imaging, detection, and specialized reactivity, should be investigated.

Along with this, a machine learning-based robotics framework would pave the way for specialized materials derivation from MOF.

Reference

Wang, C., Yao, Y., Li, J. & Yamauchi, Y., (2022) Metal–Organic Frameworks: A Robust Platform for Creating Nanoarchitectured Carbon Materials. Accounts of Materials Research. Available at: https://pubs.acs.org/doi/abs/10.1021/accountsmr.1c00258

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.