A method for fabricating single-crystal graphene sheets on large-scale electrically insulating substrates could aid in the development of next-generation nanomaterial-based products such as very light and thin touchscreens, wearable electronics and solar cells.

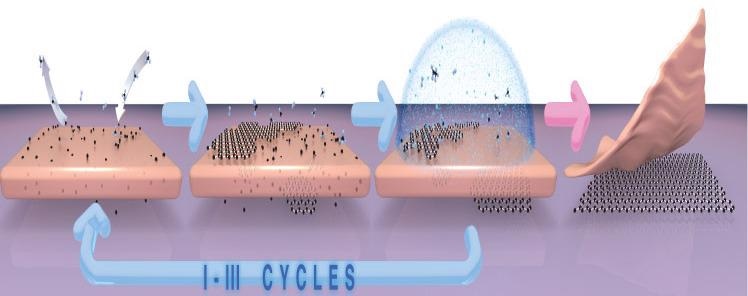

A schematic illustration of the single-crystal graphene sheets grown on an insulating substrate. The method could enhance next-generation nanomaterial-based devices. Image Credit: Springer Nature; Reproduced with permission from Junzhu Li et al (2022).

A schematic illustration of the single-crystal graphene sheets grown on an insulating substrate. The method could enhance next-generation nanomaterial-based devices. Image Credit: Springer Nature; Reproduced with permission from Junzhu Li et al (2022).

Insulating supports are required for the majority of graphene-based electrical devices. Graphene films for industrial usage, on the other hand, are often generated on a metal substrate, like copper foil, before being moved to insulating support for device manufacturing. This technique can introduce contaminants into the gadget, lowering its performance. Attempts to develop graphene on insulating supports have failed to yield the high-quality single crystals needed.

If graphene can be grown on an insulating substrate with a clean interface, certain devices might function better. This also opens the door to new types of graphene-based nanodevices.

Bo Tian, Study Co-Lead and PhD Student, King Abdullah University of Science and Technology

Tian conducted the research under Xixiang Zhang’s supervision.

Zhang, Tian, and colleagues from Asia and Europe adjusted the chemical vapor deposition process, which depends on copper-catalyzed methane breakdown into carbon precursors, to produce smooth single-crystal graphene monolayers on wafer-scale single-crystal substrates known as a c-plane sapphire.

On the sapphire layer, the scientists transformed polycrystalline copper foil into its single-crystal equivalent Cu(111) and injected active carbon atoms from the metal substrate-catalyzed methane breakdown. The carbon atoms migrated through the metallic layer toward the copper–sapphire interface, which served as a template, forming well-oriented graphene islands that eventually combined to create a sheet after multiple growth cycles.

Tian claims that, in addition to weak surface contacts, the copper film and sapphire had identical crystal lattice symmetry to graphene, which justifies the graphene monolayer’s crystalline structure.

To allow carbon diffusion, the scientists used a hydrogen–argon plasma to scrape away any graphene that had accumulated on top of the copper sheet. They submerged the samples in liquid nitrogen before quickly heating them to 500 degrees Celsius, which allowed researchers to peel off the copper sheet while preserving the graphene monolayer.

Field-effect transistors made from sapphire-grown single-crystal graphene monolayers performed well and had increased carrier mobilities. Tian argues that the increased crystallinity and fewer folds on the surface of graphene grown on sapphire contribute to better electronic effectiveness.

“Our team is now trying to grow other two-dimensional materials on the insulator-supported graphene to build functionalized large-scale heterostructures,” Tian concludes. Upcoming nanodevices are likely to benefit from these heterostructures bound together by van der Waals interactions.

Schematic animation

Schematic animation of direct growth of single-crystalline graphene on insulating substrates by MPE–CVD. Video Credit: Springer Nature; Li, J. et al. (2022)

Journal Reference:

Li, J., et al. (2022) Wafer-scale single-crystal monolayer graphene grown on a sapphire substrate. Nature Materials. doi.org/10.1038/s41563-021-01174-1.