Reviewed by Alex SmithApr 26 2022

Diamond is more than a lovely gem, and physicists like it because of its flaws. One of the most promising quantum materials is diamond nanocrystals, specifically, nanodiamonds with point defects such as nitrogen-vacancy (NV) centers.

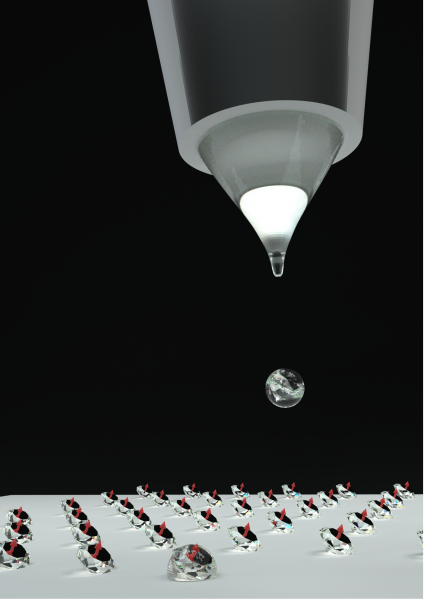

Nano-precision printing of NV-center nanodiamonds using the new technology. Image Credit: The University of Hong Kong.

Nano-precision printing of NV-center nanodiamonds using the new technology. Image Credit: The University of Hong Kong.

The ability to arrange individual NV centers on integrated circuits at will is a key need for realizing practical applications. This is essential for adopting quantum technologies, which have resulted in several new opportunities and sectors including quantum communications, quantum computers and quantum metrology.

However, for achieving nanoscale precision, flexibility, cost-effectiveness and effective coupling with a broad range of nanophotonic circuitries, a universal and flexible method is still in high demand.

There are several methods available to arrange the nanodiamonds with NV centers on different substrates and circuits, including the advanced “pick-and-place” nanomanipulation approach. However, imprecise positioning precision, limited throughput and process complexity continue to be a problem.

Dr. Ji Tae Kim from the Department of Mechanical Engineering and Dr. Zhiqin Chu from the Department of Electrical and Electronic Engineering at the University of Hong Kong (HKU) have devised a quantum-level nano-precision printing technique for nitrogen-vacancy (NV) centers in diamond.

This unique technology is both practical and cost-effective, opening the door for the manufacture of quantum information processing, quantum computing and biosensing devices.

This breakthrough was reported in the journal Advanced Science, which was featured on the journal’s Back Cover. The innovation has been granted a patent in the United States.

The NV center is the most prevalent defect in nanodiamonds and is a point defect in the diamond lattice. Due to its promising quantum states even at room temperature, it has surfaced as a powerhouse for quantum systems, whereas other quantum systems, such as the superconducting quantum interference device, can only start operating at cryogenic temperatures, ranging from -150 °C (-238 °F) to absolute zero (-273 °C or -460 °F).

With its optically addressable spin degrees of freedom, this atom-like solid-state device provides the key functions for serving as the quantum bit and/or quantum sensor in solid-state quantum computers.

“Diamond is the hardest material, so it is difficult to craft.”

The researchers have devised a novel approach to this problem. For installing NV-centers directly on universal substrates, scientists used electrical discharge of nanodiamond-laden liquid droplets with sub-attoliter (< 10-18 liter) volume.

To the best of our knowledge, the developed technique, for the first time, shows sub-wavelength positional accuracy, single-defect-level quantity control, and freeform patterning capabilities, meeting the technological requirements which marks a significant breakthrough in quantum device manufacturing.

Dr. Zhiqin Chu, Electrical and Electronic Engineering, University of Hong Kong

Journal Reference:

Xu, Z., et al. (2022) On-Demand, Direct Printing of Nanodiamonds at the Quantum Level. Advanced Science. doi.org/10.1002/advs.202103598.