Regarding the synthesis of graphene, a study printed in the journal ACS Applied Electronic Materials presents the use of biowaste to develop graphene-based materials for electronic applications.

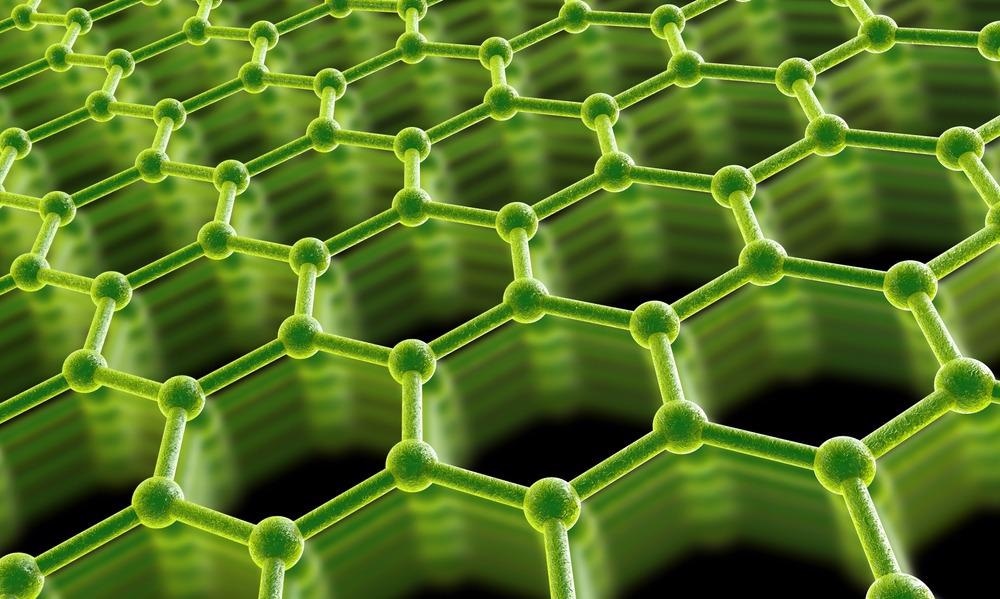

Study: Sustainable Approach for Developing Graphene-Based Materials from Natural Resources and Biowastes for Electronic Applications. Image Credit: Kateryna Kon/Shutterstock.com

What Makes Graphene So Special?

Graphene is a two-dimensional hexagonal lattice made up of a squashed layer of carbon atoms held together by powerful sp2-C bonds. Graphene has recently prompted a huge amount of research due to its outstanding mechanical and optical-electronic properties.

It has been observed that alteration of graphene strands results in improved variable characteristics such as the adsorption performance, hydrophobicity, antibacterial activity, and conductivity, which are useful for a wide variety of applications.

Graphene-based materials created from natural resources provide an attractive opportunity to exhibit explicit utility through covalent bonding with coupling experts. These experts alter the properties of the carbonaceous phase while keeping it unchanged, permitting the creation of one-of-a-kind multipurpose graphene-based compounds.

One of the primary consequences of graphene's prominence in materials science is the hunt for simple, cost-effective, and scalable ways to produce graphene.

Top-Down Synthesis Vs. Bottom-Up Synthesis

There are two types of synthesis techniques: top-down and bottom-up. Top-down manufacturing methods are those which attempt to break a molecular structure down to its atomic levels. Examples of common top-down synthesis methods are graphite intercalation, mechanical exfoliation, electrochemical exfoliation, graphene oxide (GO) reduction, and carbon nanotube cutting.

In bottom-up techniques, a carbon source is used as the basic building block, and variants of graphene are created by chemical ablation of 3D graphite, which leads to the exfoliation of single-layered graphene. Methods that are classified as bottom-up methods include chemical vapor deposition and metal-carbon casting growth.

The Rise of Graphene Oxide

Ever since Hummers' study, it has been established that the oxidation of graphite produces exfoliated films of GO. Single graphene films are formed whenever GO is exposed to powerful reducing reagents, and it undergoes significant reduction often without restacking.

Variants of graphene have applications as diverse as polymer nanocomposites, electrochemical devices, and heterogeneous catalysis. Nevertheless, significant amounts of solvents, highly energetic mixing, and electrochemical treatment are still required to synthesize the various modifications of graphene.

Flash Graphene Synthesis

The flash graphene process synthesizes graphene with the help of natural biological waste. The most significant advantage of flash graphene synthesis is that there are no solvents, reacting gases, or furnaces used in the process.

The yields of the synthesis are determined by the quantity of carbon in the source. A high carbon source may provide yields starting from 80 percent to anywhere close to 90 percent, with the purity of carbon exceeding 99 percent. This process also ensures that there is no requirement for any purifying procedure.

This advantageous waste management strategy may contribute to the accomplishment of waste minimization and the inception of a municipal waste management scheme that benefits the economy.

Conclusions

In this study, the team presented the synthesis of graphene and variants of graphene using sustainable natural resources. These resources include flowers, culinary goods, and biowaste.

The team also talked about numerous forms of solid carbon-based waste with graphitization potential that may be utilized to make excellent-quality graphene films. Additionally, it was noted by the team that these methods enabled the efficient transformation of low-value, harmful waste into useful and excellent-quality graphene-based NPs.

The team highlighted that graphene might provide an efficient metal-free replacement for developing wearable electronics that continue to function even after being twisted, stretched, and deformed.

It was pointed out that graphene and associated materials are now garnering interest in numerous sectors because of their programmable physical characteristics, remarkable shape, and increased chemical, electrical, and thermal capabilities.

The team concluded that, even though the commercialization of a revolutionary material may take at least a couple of decades, it is believed by the experts that graphene will be the first to meet that deadline.

Reference

Jindal, S., Anand, R., Niharika Sharma, N., Nisha Yadav, N., Mudgal, D., Mishra, R., & Mishra, V. (2022). Sustainable Approach for Developing Graphene-Based Materials from Natural Resources and Biowastes for Electronic Applications. ACS Applied Electronic Materials. Available at: https://doi.org/10.1021/acsaelm.2c00097

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.