Nanocapsules are widely utilized in various industries such as drug delivery systems. The recent study published in Langmuir focuses on the analysis of buckling and collapse of nanocapsules employing real-time Transmission Electron Microscopy (TEM). The results are useful in understanding the buckling mechanism and can help to improve the design aspect of such structures.

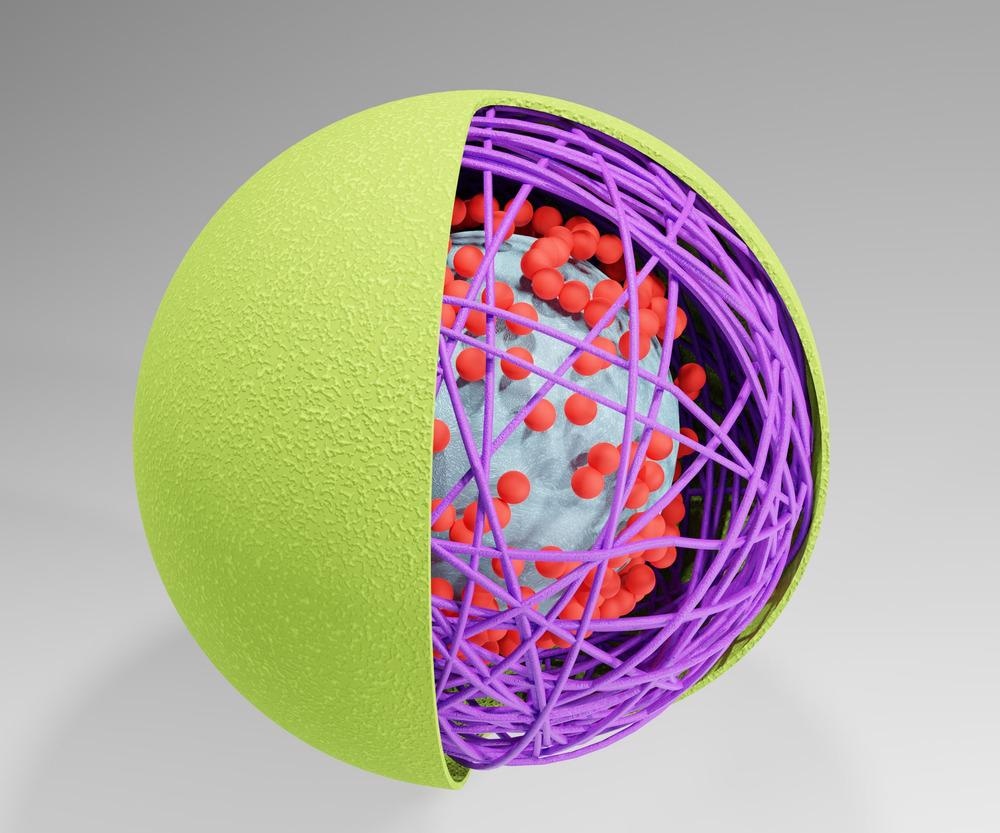

Study: Dynamics of Polymer Nanocapsule Buckling and Collapse Revealed by In Situ Liquid-Phase TEM. Image Credit: Love Employee/Shutterstock.com

What are Nanocapsules?

Nanocapsules are made up of hollow nanoparticles with a diameter range of 10 to 200 nm that enclose fluids within a spherical shell. The structures are made of chemical, organic, and polymeric materials that have been created to discharge the encapsulated components with precise spatial and temporal regulation.

The capacity to segregate and then discharge chemical products with precise accuracy has many applications, including medication delivery, agricultural studies, cosmetology, pressure sensors, physical controllers, cell anodes, and carbon sequestration.

Prediction of Buckling Behavior

The buckling of geometrical shapes specifically spherical nanocapsules is a very complex concept. A shell can bend into a variety of morphologies in terms of size, structure, flaws, and frequency of cargo discharge, ranging from colloidal particles in the shape of a bowl with solitary grooves to nanocapsules with many protrusions, wrinkled topologies, or flattened discs.

Numerous paths for the bucking process are known, including those resulting in the same end topologies.

How do Nanocapsules work?

Changes in acidity or osmolarity, as well as chemical exposure, temperature, radiation, electromagnetic field, shearing, vibrations, or mechanical forces, can all promote cargo discharge. Such activation is based on the principle that its thin walls render them sensitive to bending and rupture under compressive stress.

Buckling is caused by the in-plane energy transfer necessary to expand or squeeze the exterior of the shell into out-of-plane momentum. Even a little in-plane surface displacement can cause substantial and sudden changes in the nanocapsule shape.

Which Capsule Geometries are Susceptible to Buckling?

As the pressure differential across the surface approaches a preset value of critical pressure, buckling occurs, exchanging wasteful in-plane straining potential for bending energy. This differential critical differential necessary to imprint or bend shells is exactly proportionate to the ratio h/R.

This ratio is closely related to design methodology as h represents the thickness of the shell of the nanocapsule. The capsule radius is denoted by R, as per conventional shell buckling theory. Thinner walls and greater diameters of nanocapsules, indicating a low h/R, are more prone to buckling.

Advantages of Studying Buckling

Precise resolution of intermittent bending phases instantaneously would help us better comprehend this complicated occurrence and its reliability on structural parameters.

These findings might help researchers develop capsules that are resistant to untimely discharge and have discharge processes that are tailored to certain uses. In theory, real-time imagery of nanocapsule breakdown might show correlations between bending and critical physical factors like shell flaws.

The knowledge gained might be used to develop techniques for selecting buckling actions that are useful to obtain non-spherical geometries that are desirable, boost cellular uptake, and facilitate interfacial aggregation.

Advantages of TEM Examinations Over Conventional Methods

Structural penetration has been utilized to explore dry hollowed shell in situ TEM examinations of buckling, but many implementations need casings that enclose or function in liquid.

The kinematics of nanocapsules and other fragile colloidal particles may now be studied with excellent temporal and spatial accuracy because of recent advances in liquid-phase TEM. The TEM might be used to capture the whole mechanics of nanocapsule disintegration.

Research Findings

The researchers demonstrated that h/R, the Föpplvon Karman number γ, and the compaction frequency δV are the most important factors in determining buckling paths. Nanocapsules with solitary protrusions, the lowest-energy structure, results from a low γ value along with a similarly lower δV value. Substantial values of γ or δV, on the other hand, create many markings that are thermodynamically confined.

The thickness to radius ratio is reduced, resulting in profound indentations. Because of the increased consistency of the finished product, solitary-protrusion bowl geometry collapse, which may be reached at low γ and δV, is preferred. Nanocapsules with a reduced elasticity are more durable and less susceptible to buckle, whereas those with a high elasticity buckle with modest pressure.

The quantitative velocity of cargo discharge is typically comparable to the nanocapsule capacity, which is another key design guideline.

The novel nano-scale method might replace complicated compressors and regulators in liquid tanks, allowing for high-throughput microscopic electronic imaging of various individual events (such as nanocrystal formation) on a specific substrate.

Reference

Alam, S. B. et. al. (2022). Dynamics of Polymer Nanocapsule Buckling and Collapse Revealed by In Situ Liquid-Phase TEM. Langmuir. Available at: https://pubs.acs.org/doi/10.1021/acs.langmuir.2c00432

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.