Incorporating single nanocrystals (NCs) into a solid-state device requires controlled nanocrystal assembly. Additionally, the assembly method should have properties like precise positioning, scalability, high process controllability, and universality.

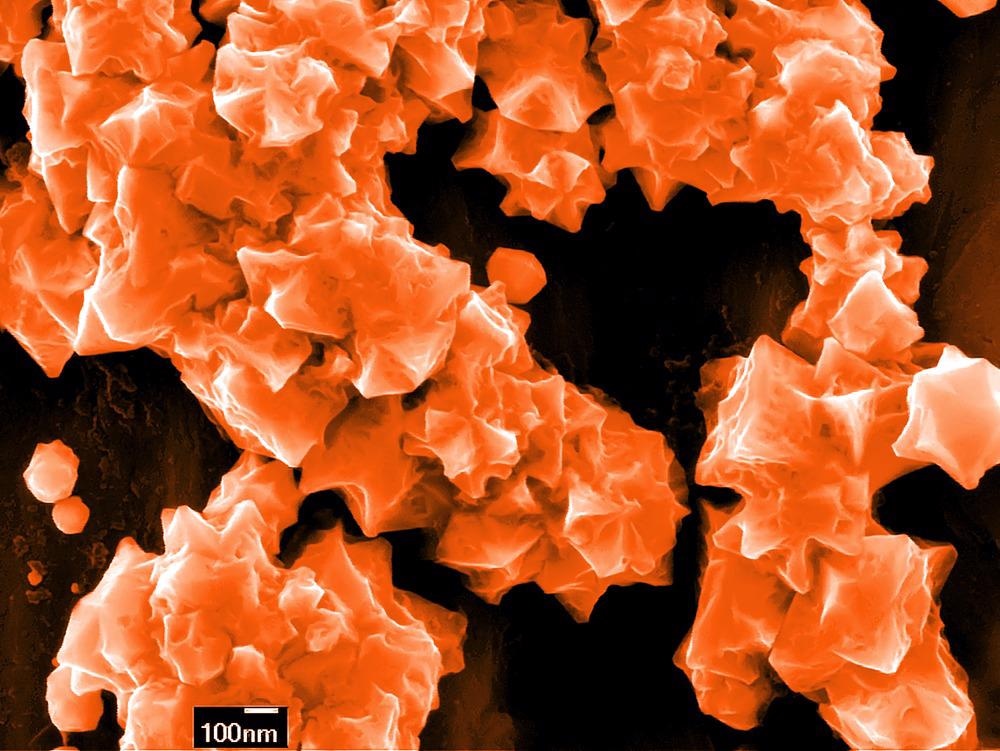

Study: A General Method for Direct Assembly of Single Nanocrystals. Image Credit: Georgy Shafeev/Shutterstock.com

In an article recently published in Advanced Optical Materials, the authors demonstrated surface templated electrophoretic deposition (STED) as a potential assembly method for a wide variety of nanocrystals.

NC Assembly Methods

Although physical and chemical vapor deposition methods help fabricate an array of single NCs on a solid substrate, the range of materials that could be deposited is still limited. Moreover, these deposition methods do not hold good for NCs with complex morphologies. Assembly of NCs may be initiated either by chemical interactions leading to self-assembly or by applied external forces leading to directed assembly. However, solution-based NC assembly is the most promising approach.

There has been considerable progress in NC’s self-assembled crystallization into two-dimensional (2D) and three-dimensional (3D) superlattices. In chemical interaction-induced self-assembly, altering temperature or pH, adding nonsolvent, solvent evaporation, or electrolyte addition can transcend interparticle forces from repulsive to weakly attractive. Furthermore, variation in interparticle spacing tunes the properties of resultant superlattices. However, the nature of forces that exist between NCs determines the final structure’s geometry for composite material.

Direct assembly is advantageous over chemical self-assembly due to the stability of NCs under external force, adjusted in space and time. Unless the external forces applied are used to orient single NCs into well-defined locations, this force generally drives the NCs to superstructure assembly.

To this end, surface templating steers individual NC’s deposition into a preordained position. Another assembly method is particle-substrate interaction-based electrostatic assembly, where the pre-functionalized substrate generates an electrostatic contrast, enabling selective adsorption of oppositely charged NCs. Optical printing is another effective method generally used to construct complex nanostructures.

STED Towards NC Assembly

In the present study, researchers focused on STED as an alternative method for NC assembly that depends on charged NC’s conventional electrophoretic deposition (EPD) under an applied electric field. However, NC deposition is affected by pre-patterned, nanoscale, conducting substrate. Uniform charge distribution in particles was the prerequisite for the successful deposition of single NCs.

Since NC deposition was favorable for the particles in solution with high electrophoretic mobility, the monodispersity of the particles was essential. Moreover, electrophoresis is carried out well in solvents with a high dielectric constant. STED could be applied to all types of NCs with a well-defined size, shape, and surface charge that sustains for an extended period.

Research Findings

Scanning electron microscopy (SEM) images of gold (Au) NCs showed a single particle array of 3 X 3 with an interparticle distance of 5 micrometers.

A template with rectangular cavities was used to assemble Au nanorods into arrays, and the template orientation controlled the final orientation of the individual rod. The researchers observed that the Au nanocubes could also be arranged into an array of square cavities and SEM images revealed that the orientation of these nanocubes within the cavity matched that of square cavities. The cavities were only 6 nanometers wider than the mean cube diameter. Although the mismatch was small, the deposition was highly efficient.

The team observed that the steric factors determined the packing of NCs. They hypothesized that the electrostatic forces also played a vital role in NC packing. Charged particles and electrolytes generated complicated electric field distribution inside the cavity. The presence of carboxyl groups on the surface of poly(methyl methacrylate) (PMMA) may also induce a charge on PMMA-based cavity walls, suggesting that the electric forces determined the particle’s final orientation and played a role in restricting the deposition per cavity to one particle.

The authors demonstrated the possibility of STED assembly in different kinds of NCs. Particles may be insulating or conducting, nonmagnetic or magnetic, or adopting different morphologies. Additionally, the team observed that the particles with smaller sizes required higher applied potential to induce the assembly process. However, an indefinite increase in applied potential may cause solvent electrolysis, template corrosion, or damaged NCs. Hence, single NCs with a particle size of less than 10 nanometers are subjected to an artificial size increase before STED assembly.

Conclusion

In conclusion, the team demonstrated the potential of STED in providing a versatile mechanism for positioning single NCs in large numbers with nanometer precision. STED is a rapid and scalable method that can work for a range of materials. Owing to the difficulty in overcoming the Brownian motion, the NCs attain a lower size limit. However, using polyelectrolyte coating or silica (SiO2) shell can increase the NC size and overcome the problem that impedes the assembly of single-molecule arrays.

Reference

Zhang, H., Liu, Y., Ashokan, A., Gao, C., Dong, Y., Kinnear, C., and Mulvaney, P. (2022). A General Method for Direct Assembly of Single Nanocrystals. Advanced Optical Materials. https://onlinelibrary.wiley.com/doi/full/10.1002/adom.202200179

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.