Graphene conductive inks have emerged as a critical element of printed electronics. In a paper published in Materials Today: Proceedings, water-based graphene conductive inks were developed using sodium dodecyl surfactant (SDS). The team analyzed how different concentrations of the SDS surfactant affected the characteristics of graphene dispersion in water.

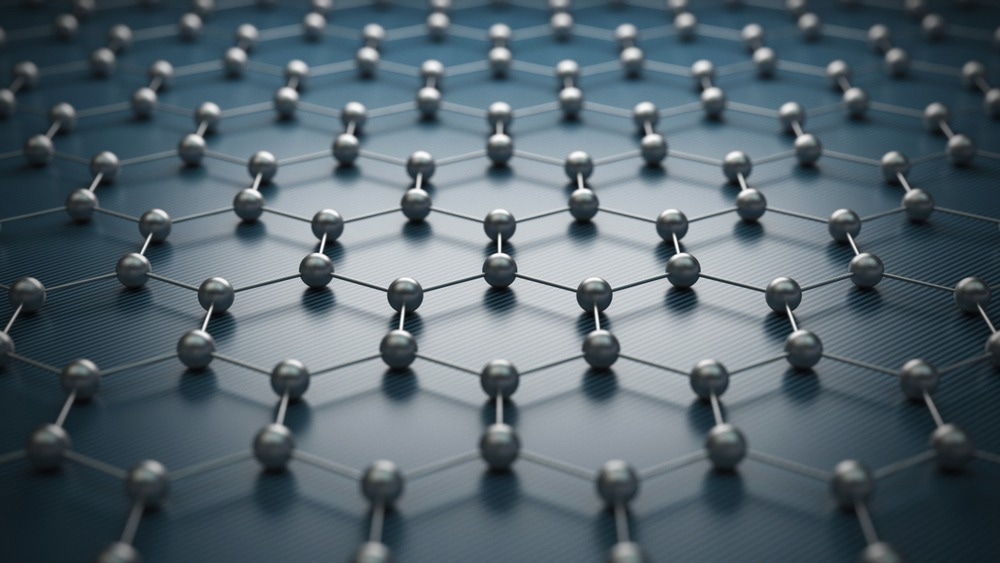

Study: Effect of sodium dodecyl concentration on the properties of graphene conductive inks. Image Credit: koya979/Shutterstock.com

Role of Conductive Inks in Printed Electronics

A thick thermoplastic mixture containing conductive nanoparticles is referred to as conductive ink. It consists of surfactants and solvents which hold the conductive substance together. Usually, the solvent and surfactants are designed to evaporate when the conductive ink is applied, so only the conductive components are left behind. Conductive inks are widely used in printed electronics.

The printed wearable electronics industry has recently seen remarkable expansion because of its potential to provide inexpensive, high-performance products for several different uses.

During the last few years, a wide range of conductive ink compositions has been formulated to create printed electronics with remarkable electric conductivities and the ability to withstand significant flexing stresses without compromising performance.

Customized arrangements of electrical qualities can be generated on various substrates, including silicon, polymers, paper, and textiles using the conductive printing technique. Inkjet printing has received a lot of interest in this regard, as it can be employed in the manufacturing of printed electronic gadgets.

Advantages of Using Graphene in Conductive Inks

Graphene is an ultra-thin nanomaterial capable of excellent electricity and heat conduction. Graphene can transport conducting charges on a non-conducting material. Moreover, it has the unique property of being insoluble.

As graphene ink is a derivative of graphene, it retains all the nanomaterial’s qualities. Graphene ink, therefore, shows remarkable electrical and thermal conductivity, allowing it to carry charges and serve as a shield between heating components. Due to its chemical inertness, graphene conductive ink does not react with other substances. Therefore, it may be easily paired with other materials for various uses.

Owing to these properties, graphene conducting ink is a popular choice among different nanotechnology-based conductive inks as a metallic constituent in printed electrical products. Solvents are essential in synthesizing graphene conductive inks to guarantee proper fluidity for printing.

Preparation of Graphene Conductive Inks

Water is a preferable solvent for preparing graphene conductive inks because it is inexpensive, readily available, non-toxic, and has an adequate boiling point. It does, however, have a strong interfacial tension of 72.8 mJm-2. Additionally, owing to the hydrophobicity of graphitic carbon, dispersing graphene in water is challenging.

Surfactants can lower interfacial tension and are often used in graphene conductive inks to increase the dispersal of graphene. Various surfactants, ionic as well as non-ionic, have been introduced to graphene suspensions.

Why Use Sodium Dodecyl Surfactant?

The use of sodium dodecyl surfactant (SDS) is common in graphene suspensions to aid in the adequate dispersal of graphene.

SDS possesses a polar as well as a non-polar hydrophilic head. There is an equal load on both the heads, so graphene adsorbs the non-polar head of the sodium dodecyl surfactant while water adsorbs the polar head, resulting in a stable graphene solution.

What Did the Researchers Do?

The team explored the influence of different sodium dodecyl surfactant concentrations on the characteristics of graphene conductive inks. Furthermore, they used inkjet printing to deposit the conductive inks onto a polyethylene terephthalate (PET) platform.

The researchers also examined the distribution of graphene in SDS-incorporated conductive inks and the hydrophilicity, electric conduction, and stability of the graphene conductive inks.

Significant Findings of the Study

In this study, the team developed graphene conductive inks through the combination of deionized water with varying concentrations of sodium dodecyl surfactant. In comparison with all the other SDS concentrations, graphene conductive inks made with 0.3 wt% SDS demonstrated greater stability, hydrophilic characteristics, and electric conductance.

When the frequency of printing rounds in 0.3 wt% SDS was raised from one to ten, the electric conductance of the printed conductive traces was improved by about 40 times.

Utilizing PET as a platform, this research may be used to create a variety of designs with high electric conductance. The findings of this study point to possible future progress in printed electronics.

Reference

Htwe, Y., Abdullah, M., & Mariatti, M. (2022). Effect of sodium dodecyl concentration on the properties of graphene conductive inks. Materials Today: Proceedings. Available at: https://doi.org/10.1016/j.matpr.2022.06.525

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.