Conventional materials used in electronic gas sensors, like chemiresistive-based nitrogen dioxide (NO2) sensors, fail to withstand ordinary wash cycles because of the simultaneous action of harsh compounds in washing solutions and mechanical damage.

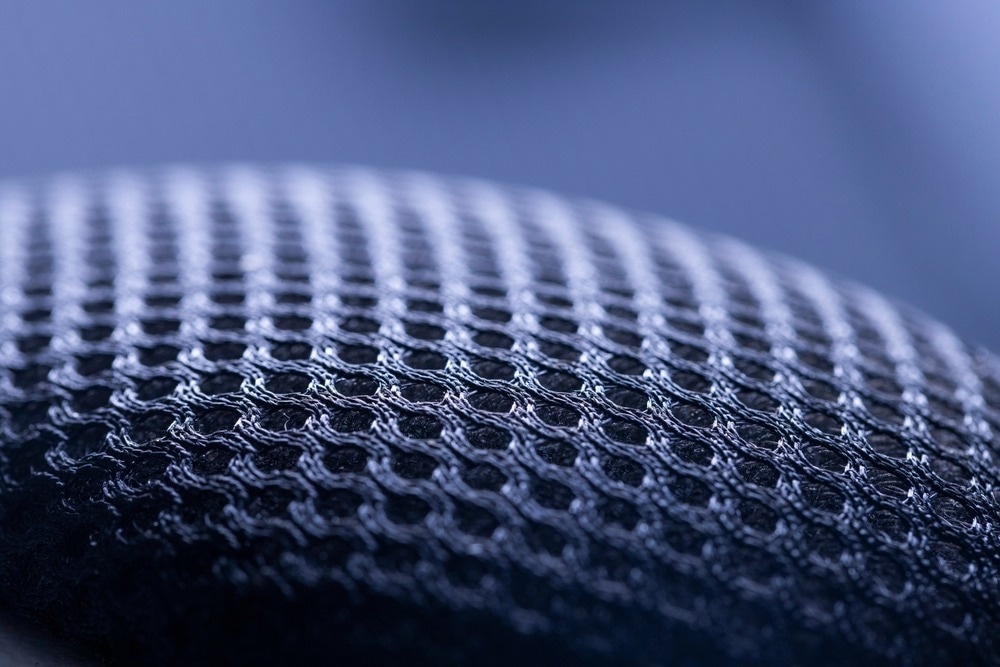

Study: Unencapsulated and washable two-dimensional material electronic-textile for NO2 sensing in ambient air. Image Credit: b.asia/Shutterstock.com

A recent study published in the journal Scientific Reports focuses on the production of very responsive NO2 sensors on nylon fabric, which is immune to regular washing cycles, to overcome this constraint.

Importance of Wearable Gas Sensors

Poor outdoor and indoor air quality can be related to thousands of preventable deaths annually. According to epidemiological research, exposure to toxin concentrations beyond the specified limits can be fatal, particularly for infants, pregnant women, and older members of the population.

The relationship between hospitalization data, emergency department visits, and pollution data over time can be used to indicate the negative effects of air pollution on the cardiac system of human beings.

However, data on air pollution is mostly gathered through a small number of air quality measurement facilities, which are established at permanent locations with a spatial range of a few kilometers in metropolitan areas and several hundred kilometers in remote rural areas.

Because of this geographical sparsity, the gathered air pollution data can vary significantly from each individual's actual levels of exposure. Wearable gas sensors, such as NO2 sensors, can overcome this difficulty since they reside in the subject's immediate environment.

Limitations of Current Wearable Gas Sensing Technologies

Next-generation portable gas sensors and devices are designed to be incorporated into the user's clothing to provide maximum user comfort. On-body patches made of flexible polymers and stiff silicon-based sensors housed in a box are two current substrates for wearable NO2 sensors.

However, the poor permeability and skin contact concerns associated with standard adhesives limit the use of on-body patches for gas sensors, causing skin damage and pain to the user. Meanwhile, traditional silicon-based electronics are often big and invasive. These constraints significantly restrict their usage in the fabrication of wearable gas sensors.

Textile Materials for Wearable Gas Sensors

Textile materials, when used as substrates for digital gas sensors, have all of the favorable characteristics, such as high elasticity, bio/skin suitability, washability, ease of integration to irregular size and shape, closeness to the monitoring site, and the capacity to be worn by the consumer for extended periods without irritation.

Potentiometric sensors, temperature sensors, touch sensors, strain gauges, pressure transducers, and humidity sensors have all been effectively incorporated into textile materials.

However, the fabrication of high precision, low limit of detection (LOD), and low working temperature (<150 °C) NO2 sensors on textile substrates have not been realized. Furthermore, a procedure for fabricating washable gas sensors, notably NO2 sensors, using transition metal dichalcogenides without encapsulating layers is yet to be established.

Development of Textile-based Novel NO2 Sensors

Nitrogen dioxide (NO2) gas is exceedingly toxic to the human body, causing major lung tissue destruction. The dangers of NO2 gas exposure to human life are enormous. As a result, real-time measurement of NO2 gas concentrations and the development of wearable NO2 sensors are extremely critical.

The researchers' aim in this work was to create textile-based NO2 sensors that could retain or even improve their sensing capability during International Standard Organization (ISO) conventional washing cycles in the absence of any encapsulating layers.

These innovative NO2 sensors were made by depositing graphene oxide (GO) and graphene oxide/molybdenum disulfide (GO/MoS2) on nylon fabric and reducing GO in-situ to reduced graphene oxide (RGO).

Key Developments of the Study

In this work, flexible, inexpensive, and biodegradable NO2 sensors were created and incorporated into textiles. The NO2 gas sensors developed are extremely sensitive to the level of NO2 in gas mixtures in both dry and moist air.

When exposed to 2 ppm of NO2, the resistance of fabricated NO2 sensors varies by 28 percent, compared to 6.5 percent for 40,000 ppm of carbon dioxide and 0 percent for 2 ppm of ammonia, demonstrating the strong NO2 selectivity of fabricated gas sensors in the presence of carbon dioxide and ammonia.

The NO2 sensors can also endure up to 50 ISO-standard wash cycles, with the sensor response improving significantly (500%) due to the 50 wash cycles.

The gas sensors were also installed with a microcontroller system, allowing the measurement data to be wirelessly sent to a mobile phone. These findings demonstrate the feasibility of embedding air quality gas sensors, particularly NO2 sensors, into washable clothes for high spatial resolution and continuous gas exposure monitoring.

Reference

Oluwasanya, P. W. et al. (2022). Unencapsulated and washable two-dimensional material electronic-textile for NO2 sensing in ambient air. Scientific Reports. Available at: https://www.nature.com/articles/s41598-022-16617-1

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.