An ancient metal known for its antimicrobial properties serves as the foundation for a materials-based disinfection solution. A team of researchers from Ames National Laboratory, Iowa State University, and the University of Buffalo created an antibacterial spray that deposits a coating of copper nanowires on high-touch surfaces in public places.

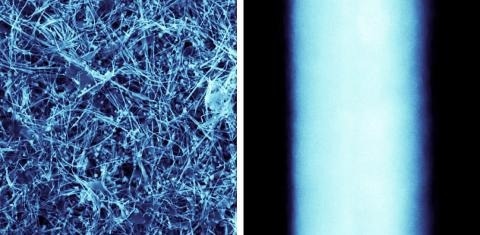

Left: Scanning electron microscopy image of the CuNW network on a copper-sprayed surface. Right: Up-close image of CuNW nanowire, which is about 60 nm in diameter, approximately 100× smaller than a human hair. Image Credit: US Department of Energy Ames National Laboratory.

Left: Scanning electron microscopy image of the CuNW network on a copper-sprayed surface. Right: Up-close image of CuNW nanowire, which is about 60 nm in diameter, approximately 100× smaller than a human hair. Image Credit: US Department of Energy Ames National Laboratory.

Copper nanowires (CuNWs) or copper-zinc nanowires (CuZnNWs) are used in the spray, which can form an antibacterial coating on a range of surfaces. The COVID-19 epidemic prompted this study, but the results have far-reaching significance.

People have used copper’s antibacterial properties to cure and prevent diseases and infections since 2400 BC. When viruses, bacteria, fungus, and yeasts come into direct contact with the metal, they become inactive.

Copper ion can penetrate the membrane of a virus and then insert itself into the RNA chain, and completely disable the virus from duplicating itself.

Jun Cui, Study Lead Researcher and Scientist, Department of Materials Science & Engineering, Iowa State University, Ames

“The DOE asked researchers, what can you do to help to mitigate this COVID situation?” Cui added. Ames Lab is well-known for its work in materials science, which does not often overlap with disease research. Cui’s team, on the other hand, came up with the concept of using copper’s antibacterial characteristics to help slow down the spread of COVID.

Cui explained that their inspiration came from another project that they were working on: a copper ink developed for printing copper nanowires used in flexible electronic devices.

So the thinking is, this is ink, and I can dilute it with water or even ethanol, and then just spray it. Whatever the surface, I spray it once and coat it with a very light layer of a copper nanowire.”

Jun Cui, Study Lead Researcher and Scientist, Department of Materials Science & Engineering, Iowa State University, Ames

The surface must first be cleansed and disinfected before applying the reformulated copper ink solution. The optimal coating should be clear and thin. The ink may be diluted with distilled water or alcohol to render it sprayable, and it operates on plastic, glass, and stainless-steel surfaces.

CuNW and CuZnNW copper inks were also tested by the team. Both inks were as effective at blocking the virus as a simple copper disk. However, the copper disk took 40 minutes to eliminate the infection, whereas the copper inks worked in just 20 minutes. Because of their larger surface area, the nanowires operated quicker.

In a comparison of the two ink coatings, CuNW inactivated the virus faster than CuZnNW over the first 10 minutes. CuZnNW, on the other hand, exhibited a more consistent and sustainable release of copper ions than CuNW, which allows the coating to be effective for a longer period of time. The researchers ultimately concluded that the CuZnNW was the best choice for a sprayable copper nanowire coating for antibacterial applications.

Cui said that this study was significant not just because of the pandemic but also because these nanowires can protect against a wide range of microorganisms.

There’s the chance that we can have a lasting impact to human society.

Jun Cui, Study Lead Researcher and Scientist, Department of Materials Science & Engineering, Iowa State University, Ames

This study is explored further in RSC Advances by C. Pan, K.S. Phadke, Z. Li, G. Ouyang, T.-h. Kim, L. Zhou, J. Slaughter, B. Bellaire, S. Ren, and J. Cui.

The research was funded by the Coronavirus CARES Act and sponsored by the DOE Office of Science via the National Virtual Biotechnology Laboratory, a collaboration of DOE national labs focusing on the response to COVID-19.

Journal Reference:

Pan, C., et al. (2022) Sprayable copper and copper–zinc nanowires inks for antiviral surface coating. RSC Advances. doi.org/10.1039/D1RA08755J.