Membrane technology is a promising technique for water treatment. In an article published in the journal Carbohydrate Polymers, titanium aluminum nitride (Ti2AlN) MAX phase was used as an inorganic additive in cellulose acetate polymeric membrane for the first time to improve its (cellulose acetate membrane) performance as a dye adsorbent from water.

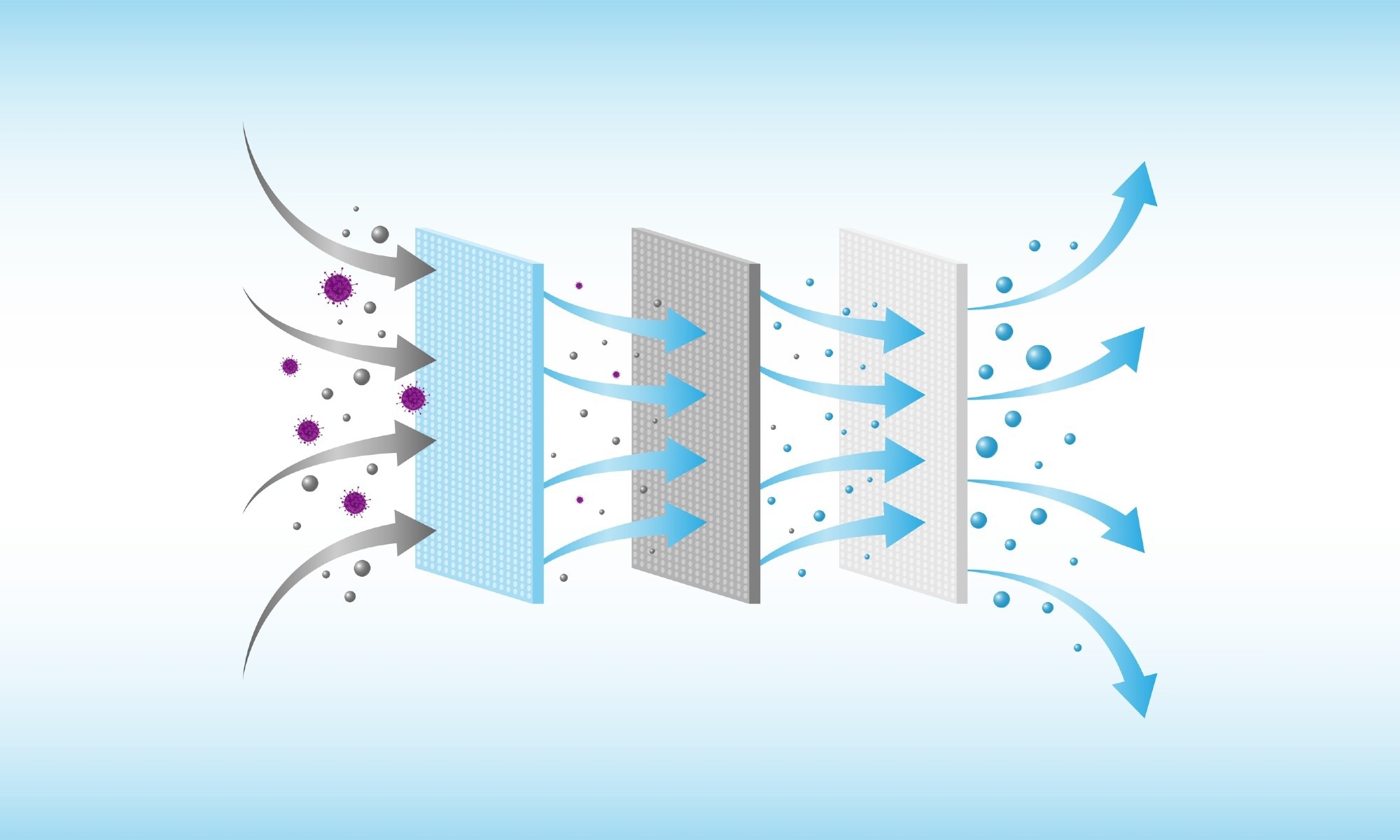

Study: Development of Ti2AlN MAX phase/cellulose acetate nanocomposite membrane for removal of dye, protein and lead ions. Image Credit: NokkieVector/Shutterstock.com

Synthesis of the Ti2AlN MAX phase via the reactive sintering method and its characterization was the first step of the present work. The hexagonal crystalline structure of the MAX phase was confirmed with an X-ray diffraction (XRD) pattern. The MAX phase served as a hydrophilic inorganic additive and, when incorporated into the matrix cellulose acetate membrane, improved the hydrophilicity and performance of the cellulose acetate membrane.

The 0.75 weight% of MAX phase in cellulose acetate membrane was considered as an optimum nanocomposite membrane that showed a three-fold enhancement in permeability during filtration of dye solutions and pure water. Moreover, this optimum nanocomposite membrane showed a 92.7% improved flux recovery ratio with a removal efficiency of: 93.5% for reactive red 120 (RR120), 70.7% for reactive black 5 (RB5), and >98% for bovine serum albumin (BSA).

This optimum nanocomposite showed 97% improved flux recovery, >55% rejection for sodium sulfate (Na2SO4) and >35% rejection of sodium chloride (NaCl). Thus, the results demonstrated the potential of materials based on the MAX phase as efficient membranes to be used in membrane technology.

Membrane Technology-Based Water Treatment and Cellulose Acetate Membrane

Reducing water consumption and wastewater reuse is necessary to prevent future water scarcity. Water treatment involves physical, chemical, and biological processes to remove the dye, salts, and metals. Physical techniques include ion exchange, adsorption, and membrane processes, while chemical processes include electrocoagulation, chemical coagulation, and oxidation. On the other hand, aerobic and anaerobic biological processes are also used for water treatment.

Membrane technology-based water treatment is the best way to reuse water and achieve desired water quality. This technology allows the effective removal of pollutants based on the applied pressure and membrane type. Thus, compared to traditional treatment, membrane-based technologies are cost-effective and sustainable processes for wastewater treatment in an environmentally friendly manner.

Cellulose acetate membrane is a porous material derived from natural cellulose. It has played an important role in membrane separation because of its good film-forming performance, high hydrophilicity, easy biodegradation, and relatively low cost. Cellulose acetate is an important membrane material due to its advantages, including wide source, non-toxicity, easy manufacturing technique, and degradable properties.

Using nanoparticles in polymeric membranes production helps in flux improvement and prevents fouling. Incorporating nanomaterials like nanotubes and nanoparticles in the size range of 4 and 100 nanometers results in an efficient polymeric membrane. The large surface area and negative charge of composite material are conducive properties to the fabricated membrane.

Ti2AlN MAX Phase/ Cellulose Acetate Nanocomposite Membrane

In the present study, the effect of the Ti2AlN MAX phase was explored on the cellulose acetate membrane’s performance. Due to their high salt retention and non-toxicity, various forms of cellulose acetate were employed in the production of membranes. Hence, cellulose acetate was the polymer of choice for the present study.

The synthesis of the Ti2AlN MAX phase was performed via the reactive sintering method, and the synthesized MAX phase was characterized using XRD, transmission electron microscopy (TEM), scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDX), dot mapping, and X-ray photoelectron spectroscopy (XPS) analysis.

The fabricated MAX/cellulose acetate composite membranes with varying content of MAX phase were prepared via the phase inversion method. The fabricated membranes were characterized for zeta potential, dot mapping, dynamic mechanical analysis (DMA), AFM techniques, and contact angle.

The antifouling property, permeability, and rejection performance were assessed using RR120, RB5, BSA, NaCl, Na2SO4, and lead (Pb)(II) solutions. The MAX/ cellulose acetate composite membrane adsorption was a physical phenomenon, and the dye residues surfaced to the top after removing the membranes. The present work is the first study on Ti2AlN MAX phase synthesis, cellulose acetate membrane production, and their application as an inorganic additive in cellulose acetate membranes.

Conclusion

To conclude, a Ti2AlN MAX phase hydrophilic material was used as an inorganic additive to improve the cellulose acetate membrane’s performance. The synthesis of the Ti2AlN MAX phase via the reactive sintering method was the first step in the present study, which was confirmed using SEM, XRD, EDX, XPS, TEM, and dot mapping analytical techniques.

The nanocomposite membranes with varying MAX phase content were fabricated via the phase

inversion method. The SEM images of the fabricated membranes revealed their asymmetric morphology with finger-like pores. Moreover, dot mapping confirmed the uniform distribution of the MAX phase in the matrix of the cellulose acetate membrane.

Reference

Keskin, B., Mehrabani, S. A. N., Arefi-Oskoui, S., Vatanpour, V., Teber, O. O., Khataee, A., Orooji, Y et al. (2022). Development of Ti2AlN MAX phase/cellulose acetate nanocomposite membrane for removal of dye, protein, and lead ions. Carbohydrate Polymers. https://doi.org/10.1016/j.carbpol.2022.119913

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.