The layer-dependent electronic structures of two-dimensional (2D) materials suggest that the physical properties of 2D or three-dimensional (3D) heterostructures can be modulated by controlling the number of layers in 2D materials. Nevertheless, identifying the thickness of 2D materials in 2D/3D heterostructures remains a challenge.

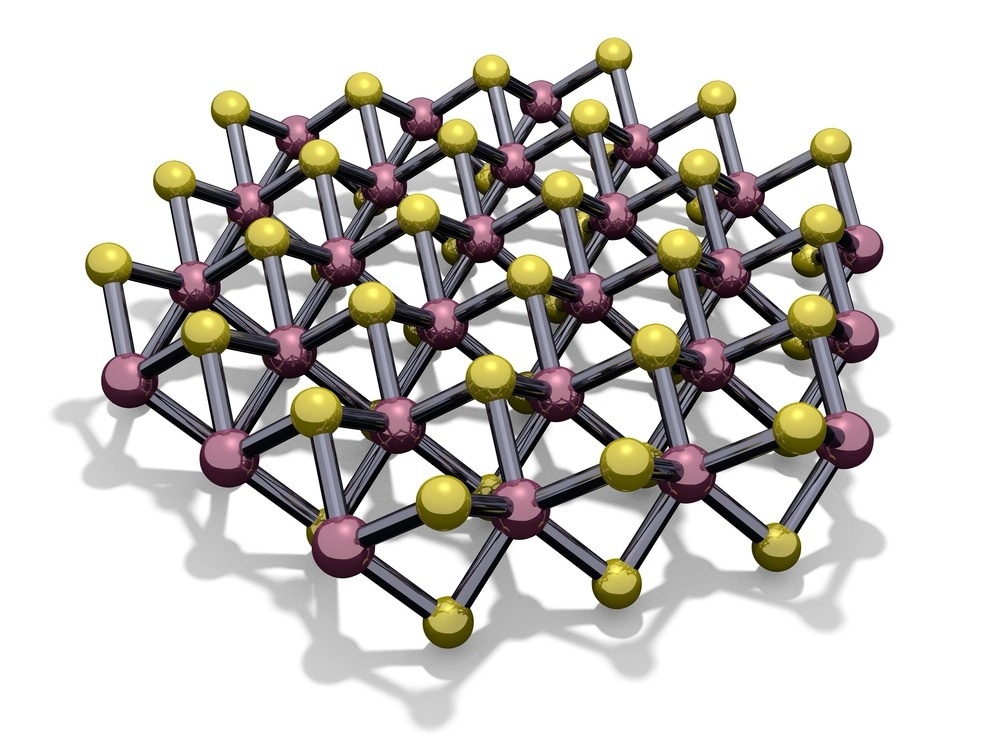

Study: Rapid Layer-Number Identification of MoS2 Nanosheet in MoS2/MoO2 Conformal Heterostructures by Color: Implications for the Fabrication of 2D/3D Heterostructures. Image Credit: ogwen/Shutterstock.com

An article published in the journal ACS Applied Nano Materials demonstrated a nondestructive and rapid optical approach for the determination of the number of layers in a molybdenum sulfide (MoS2) nanosheet in a MoS2/molybdenum oxide (MoO2) conformal heterostructures fabricated via chemical vapor deposition (CVD).

The optical color charts of MoS2/MoO2 heterostructures, consisting of the different number of layers of MoS2 nanosheet were calculated theoretically from a four-layer reflection model whose construction was based on Fresnel laws. The derived color charts in the present study fitted well with optical microscopy images of MoS2/MoO2 heterostructures. Furthermore, the number of layers of MoS2 nanosheets in MoS2/MoO2 heterostructures was verified using photoluminescence (PL) spectroscopy, Raman spectroscopy, as well as annular dark-field scanning transmission electron microscopy (ADFSTEM).

The contrast of MoS2/MoO2 heterostructure was regulated by the incident light’s wavelength, which was validated by the experimental observation and theoretical model. The results proved that the current method was a rapid technique for identifying the number of layers of 2D materials in 2D/3D heterostructures, thus benefitting the application and fabrication of 2D/3D heterostructures.

2D Materials and Their Heterostructures

2D materials and their heterostructures are excellent for fabricating next-generation optical and photonic devices. These 2D materials consist of semiconductors, half-metals, and insulators with unprecedented electronic, physical, optical, and mechanical properties since the discovery of graphene. The band structure of MoS2 2D semiconductors depends on the number of layers.

As the thickness of MoS2 decreases from bulk to monolayer, the indirect bandgap transitions to a direct bandgap. The band structure of MoS2 2D materials depends on the number of layers that facilitates their application in high-detectivity phototransistors with a wide spectral response and low-power-consumption field-effect transistors (FET). 2D materials are the building blocks that can be integrated into conventional 3D materials to form 2D/3D hybrid heterostructures with unique properties, which enable their application in electronic and optoelectronics.

MoS2-metallic material heterostructures form heterojunctions with traditional semiconductors and serve as promising candidates for their applications in electronic devices due to the natural doping at the interface. The stable neutral excitons and negative trions absent in monolayered MoS2 are found in MoS2/MoO2 heterostructures.

It is challenging to determine the number of layers in conformal MoS2/MoO2 heterostructures using conventional methods like atomic force microscopy (AFM) and Raman spectroscopy due to their limitation. On the other hand, high-resolution transmission electron microscopy (HR-TEM) requires complex sample preparation. To this end, optical microscopy is a quick, cost-effective, and convenient method to characterize 2D materials. Moreover, identifying the number of layers in 2D/3D conformal heterostructure’s 2D materials remains unexplored.

Rapid Layer-Number Identification of 2D Materials in 2D/3D Conformal Heterostructures

In the present work, a Fresnel laws-based four-layer reflection model was built, and the MoS2/MoO2 conformal heterostructure’s reflection spectrum was calculated on a silica (SiO2) / silicon (Si) substrate. The reflection spectrum was thus calculated, and the International Commission on Illumination (CIE) color was leveraged to establish the color chart of MoS2/MoO2 heterostructures with the different number of layers of the 2D materials, MoS2 nanosheets.

The color chart fitted with the MoS2/MoO2 heterostructure’s optical microscope images. Furthermore, the number of layers of 2D materials, MoS2 nanosheets was verified using PL and Raman spectroscopic techniques along with ADF-STEM characterization.

The role of SiO2 in SiO2/Si substrate thickness and the influence of incident light’s wavelength on MoS2/MoO2 heterostructure’s optical contrast was also investigated. The obtained results provided a quick and nondestructive technique to determine the number of layers of 2D materials in 2D/3D conformal heterostructures.

Conclusion

To conclude, an optical method was proposed for rapidly determining the number of layers of 2D materials, MoS2 nanosheets in a MoS2/MoO2 conformal heterostructure. The optical microscope images of the heterostructures were compared with the calculated color bar, established by combining the reflection spectrum of 2D/3D heterostructures and the International Commission on Illumination (CIE) color space.

A Fresnel law-based four-layer reflection model was used to calculate the reflection spectrum of 2D/3D heterostructures. Moreover, the accuracy of the calculated color bar was validated using PL and Raman spectroscopic studies along with ADF-STEM characterization.

The experimental and calculated results showed that the maximum contrast of MoS2/MoO2 heterostructures was efficiently regulated by the incident light’s wavelength. The results proved that the current approach is a rapid and nondestructive approach toward determining the number of layers of 2D materials in 2D/3D conformal heterostructures, benefiting the applications and fabrication of 2D/3D conformal heterostructures.

Reference

Wu, H., Li, N., Tong, P., Yu, P., Zhao, J. (2022). Rapid Layer-Number Identification of MoS2 Nanosheet in MoS2/MoO2 Conformal Heterostructures by Color: Implications for the Fabrication of 2D/3D Heterostructures. ACS Applied Nano Materials. https://pubs.acs.org/doi/10.1021/acsanm.2c02086

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.