The print medium in direct ink writing (DIW) is in the liquid phase (ink) that is dispensed out of the nozzle under controlled flow rates to be deposited in a pre-defined path to fabricate three-dimensional (3D) structures layer-by-layer.

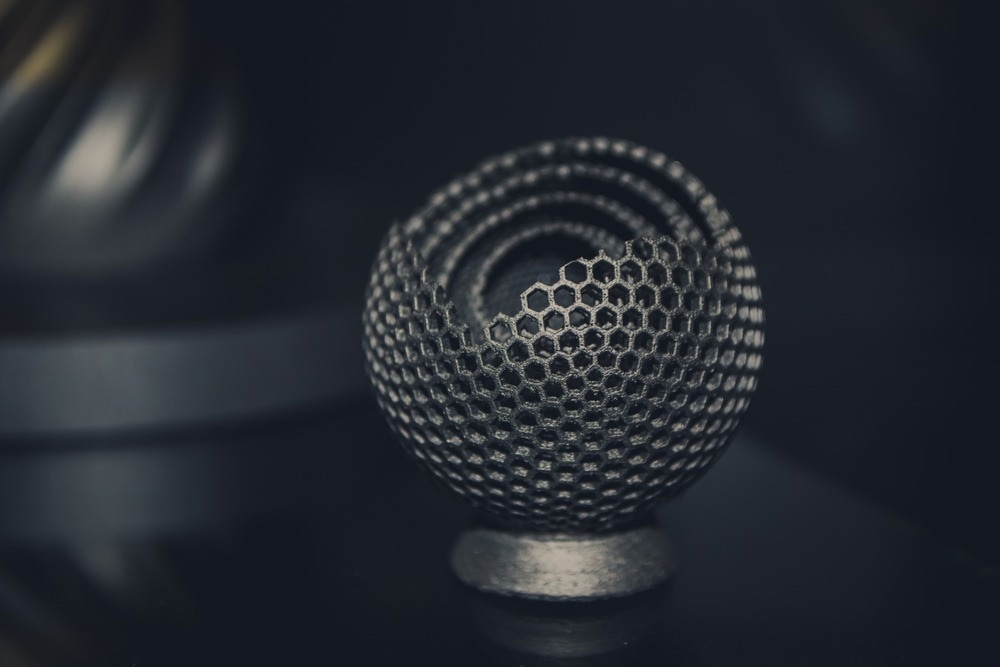

Study: Additive manufacturing of nanotube-loaded thermosets via direct ink writing and radio-frequency heating and curing. Image Credit: MarinaGrigorivna/Shutterstock.com

While the conventional DIW of thermosetting resins depends on viscosity, cross-linking chemistries, and curing in an oven, the new approach published in the journal Carbon discussed the use of a radio frequency (RF) applicator for spontaneous heating of composite resins in additive manufacturing.

The co-planar RF applicator generated an electric field that was used to quickly heat and cure composite resins during additive manufacturing, avoiding an additional step for curing the samples. The print-and-cure repetitive cycle in the present approach allowed the printing of multilayered structures with high resolution.

The RF applicator partially cured the extruded layer before the deposition of the subsequent layer, maintaining the structural integrity of the printed part. Compared to the conventional manufacturing process, the current method decreased the touch time and increased throughput. Thus, the present work demonstrated that RF heating is a convenient alternative to traditional oven-based curing methods.

Additive Manufacturing in 3D Printing

Heating and curing the thermosetting polymers form cross-linked networks that feature high mechanical strength, thermal stability, and resistance to chemical degradation. These properties make thermosets desirable for various applications in batteries, aerospace, and automotive structures.

Conventional thermosetting polymer manufacturing methods use molds for curing the resin matrices in a high-temperature oven. However, these methods are slow, consume high energy and labor, and require part-specific molds that are difficult to achieve.

The above limitations of conventional manufacturing methods are overcome by additive manufacturing, allowing faster and more efficient production of structures with customized geometries. 3D printing is an additive manufacturing technique for fabricating a wide range of structures and complex geometries from 3D model data. The process consists of printing successive layers of materials, formed on top of each other.

Additive manufacturing of cross-linkable resins using DIW printing was previously restricted to photocurable materials. Although this 3D printing could be applied to print dual-cure resins, these required incorporating photocurable materials into thermosets to manufacture light and chemically activated resin.

However, the dual-cure method alters the resin chemistry and makes the material ultraviolet (UV) curable, limiting the use of photocurable resins. On the other hand, thermoset’s additive manufacturing based on frontal polymerization (FROMP) involves propagating reaction wave that allows the initial monomer’s rapid cross-linking. However, this method restricts the number of printable resin chemistries.

Additive Manufacturing via DIW and RF Heating and Curing

RF heating has better energy efficiency and low infrastructure requirement, providing faster heating rates than conventional heating methods. Thus, replacing traditional ovens with non-contact RF applicators can permit out-of-oven curing in additive manufacturing.

While previous studies highlighted the fabrication of multilayered structures using RF heating for curing carbon nanotube (CNT)-filled thermosetting epoxies. The present study demonstrated a new process that involved layer-by-layer, print, and cure cycles for multilayered additive manufacturing.

The methods reported to date had limited resolution of the printed multilayered structure due to the heat diffusion in the resin reservoir, leading to rough edges and surfaces. However, the present method resulted in the high-resolution of the fabricated multilayered structures with smooth surfaces and void-free morphology, demonstrating the advantages of RF heating in additive manufacturing.

In the present study, each printed layer using a DIW printer was partially cured using RF heating before the deposition of the subsequent layer. The print-cure cycle helped maintain the integrity of the printed structure, supporting itself without collapsing the subsequent printed layers.

Although previous studies mentioned the use of RF heating for curing CNT-filled thermosetting epoxies, the present work highlighted the changes in rheological properties of the resin on the addition of CNTs, allowing DIW of resin without the midway collapsing of the print. Moreover, the addition of CNTs improved the electrical conductivity of the resins.

Conclusion

To summarize, a novel method was demonstrated for additive manufacturing of thermoset nanocomposites via DIW. The repetitive cycle of print-and-cure allowed the construction of multilayered thermoset parts, avoiding the use of novel chemistries or viscosity modifying agents in additive manufacturing.

The RF response and rheological properties of the resin were analyzed with different carbon nanotube loadings, evaluating the suitable carbon nanotube loading before printing complex shapes with high resolution. Thermochemical characterization of printed resins showed that the sample cured via RF heating had higher storage moduli values than oven-cured samples.

Additionally, RF-cured samples showed better strength in tensile testing than their oven-cured counterparts due to void-free and smooth morphology obtained via the RF curing process, as observed in scanning electron microscope (SEM) images.

The present work demonstrated DIW printing and localized RF heating as a convenient approach for additive manufacturing thermoset nanocomposites. Simulation results showed the prospects of additive manufacturing methodology in free-form printing of complex shapes.

Reference

Sarmah, A et al. (2022). Additive manufacturing of nanotube-loaded thermosets via direct ink writing and radio-frequency heating and curing. Carbon. https://www.sciencedirect.com/science/article/pii/S0008622322006868

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.