The orientation control and the production of nanoscale hierarchical systems, such as bio-nanofibers and nanoparticles, have recently received significant scientific attention for developing advanced functional nanomaterials.

Study: One-Pot Hierarchical Structuring of Nanocellulose by Electrophoretic Deposition. Image Credit: Yurchanka Siarhei/Shutterstock.com

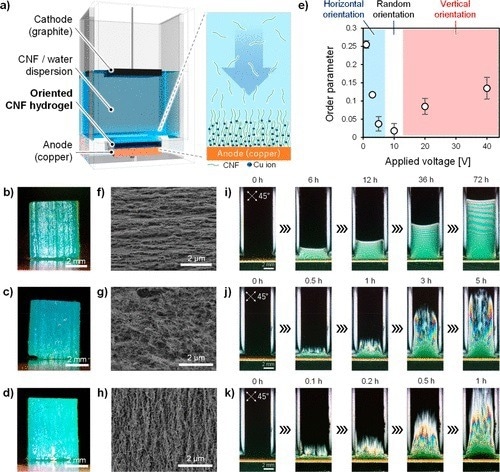

A recent study in the journal ACS Nano describes a straightforward and adaptable technique for creating complex hierarchical structures using electrophoretic and electrolytic deposition. Cellulose nanofibers (CNFs), employed as model substances in the study, are produced on an anode in an aqueous environment and flawlessly orientated horizontally and vertically by modulating the voltage level between the electrodes.

Figure 1. (a) Formation of oriented CNF hydrogel on the anode by sandwiching a CNF/water dispersion between the anode and cathode and applying a DC voltage between them. Oriented CNF hydrogels prepared at applied voltages of (b) 1, (c) 10, and (d) 40 V. CNF orientations at various applied voltages were investigated by (e) wide-angle X-ray diffractometry (WAXD), (f–h) field-emission scanning electron microscopy (FE-SEM), and (i–k) cross-polarizer-based techniques.

Orientation Control in Nanoscale Hierarchical Structures

Many living species in the natural world use nanoscale materials, such as nanofibers, to create highly robust and efficient hierarchical structures.

Plants, for instance, possess cellulose nanofibers (CNFs) that are hierarchically aligned and produce a lightweight and durable framework. The phenomena of anisotropic drying and contracting generated by hierarchically aligned CNF structures contribute to the reproduction of organisms.

Additionally, the cartilage in our bones contains highly ordered collagen nanofibers that offer external lubrication and padding. Maintaining the alignment and hierarchical structures of nanostructured materials is, therefore, essential for the survival of living creatures.

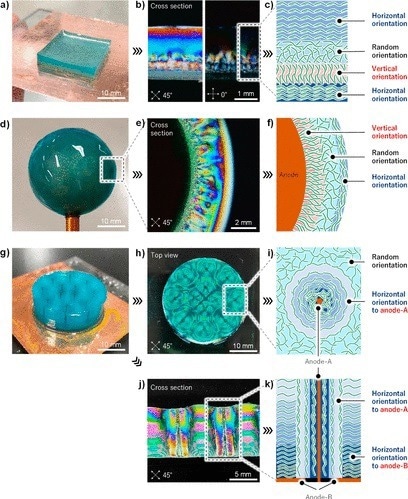

Figure 2. (a) Multilayered CNF hydrogel. (b) Cross-section of the multilayered CNF hydrogel observed through a cross-polarizer. (c) By controlling the applied voltage, CNFs were deposited in the order horizontal, vertical, random, and horizontal with respect to the anode. (d) Cartilage-like CNF hydrogel formed around a spherical electrode. (e) Cross-section observed through a cross-polarizer. (f) Corresponding schematic diagram. (g) Plant-stem-like CNF hydrogel prepared by combining wire and flat electrodes. (h, j) Corresponding cross-section. (i, k) Corresponding schematic diagram.

Typical Orientation Control Methods: Applications and Limitations

The capacity to structurally manipulate nanomaterials has sparked significant interest in attaining certain functionalities.

Conventional orientation control techniques such as shearing, extending, 3D printing, and directional freezing are currently used to alter the alignment of nanomaterials like nanofibers and nanotubes. Among them, 3D printing is an efficient approach that allows for both orientation control and shaping.

In recent years, directional freezing has also gained much popularity because of its capacity to manage orientation and morphology on a multiscale. These approaches are incredibly adaptable and have several uses in industries as diverse as plastic waste management and medical sanitation.

However, adopting a simple procedure to accomplish multiaxial alignment control, multiscale organization, and molding remains problematic.

Figure 3. (a) Three-dimensional electrode, (b) horizontally oriented CNF hydrogel fixed on its surface, and (c, d) molded CNF film after drying the CNF hydrogel. Similarly obtained (e) cylindrical, (f) flower-like, and (g) mouthpiece-shaped molded CNF films. (h) Combining mask patterning, porous substrates, and vertically oriented CNFs. (i) CNF hydrogels with sharp structures fixed on porous substrates. (j) CNF microneedles after drying.

Highlights of the Current Study

Single-use plastics have saved countless lives by increasing cleanliness in health care. However, the sheer volume of plastic garbage, which may take hundreds to thousands of years to disintegrate, is a worldwide environmental disaster. The authors of the study were motivated by cellulose nanofibers while examining the global demand for a plastic alternative.

Ultrafine cellulose nanofibers aid plants in maintaining stiff yet lightweight structures; for example, wood can be made more durable than steel on a pound-for-pound basis. Such nanofibers have been a hot topic of study in synthetic materials and other bioengineering applications because of their capacity to adjust their hierarchical structure.

In this respect, the researchers created an electrophoretic and electrochemical approach for the simple and adaptable structural control of nanostructured materials.

Electrophoretic distribution of cellulose nanofibers, nanoparticles, and chitosan has recently been used as a coating or film production process. Existing studies, however, have only accomplished random orientation or chiral nematic alignment by self-assembly.

Important Findings of the Research

In this work, negatively polarized cellulose nanofibers in aqueous solutions were employed as model substances. Cellulose nanofibers were electrophoretically and electrolytically formed on the anode substrate in a horizontal, randomized, or vertical direction by simply altering the voltage level.

A layered hydrogel with alternate nanofiber orientations was also readily created, mimicking biological tissue.

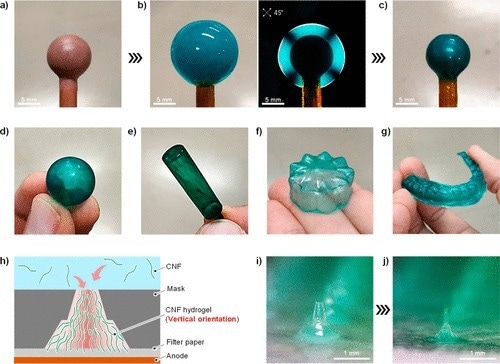

“We easily prepared complex architectures, such as microneedles and mouthpiece molds," says Takaaki Kasuga, Lead and Senior Author of the current study. "The uniform nanofiber orientation helped suppress hydrogel cracking, and thus resulted in a smooth surface, upon drying."

This study's approach is not restricted to cellulose nanofibers. For instance, the researchers also utilized sodium alginate and nano clay. Therefore, using this strategy, composite materials with regulated nanoscale orientations are similarly simple to produce as cellulose nanofibers.

The simple fabrication of complicated, hierarchical biomaterials and moldings across a wide variety of spatial scales is an obvious application of this research. Such environmentally friendly hydrogels and moldings will be valuable in the healthcare system, biotechnology, and other industries, reducing the demand for petroleum-based polymers.

Reference

Kasuga, T. et al. (2022). One-Pot Hierarchical Structuring of Nanocellulose by Electrophoretic Deposition. ACS Nano. Available at: https://doi.org/10.1021/acsnano.2c06392

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.