In recent years EV sales and the adoption of alternative energy sources have picked up speed as people embrace the transition from conventional fossil-based fuels to more sustainable alternatives. Yet, one of the major questions still circulating is which kind of alternative fuel is best for consumers, the market, and most importantly, the planet.

Image Credit: vchal/Shutterstock.com

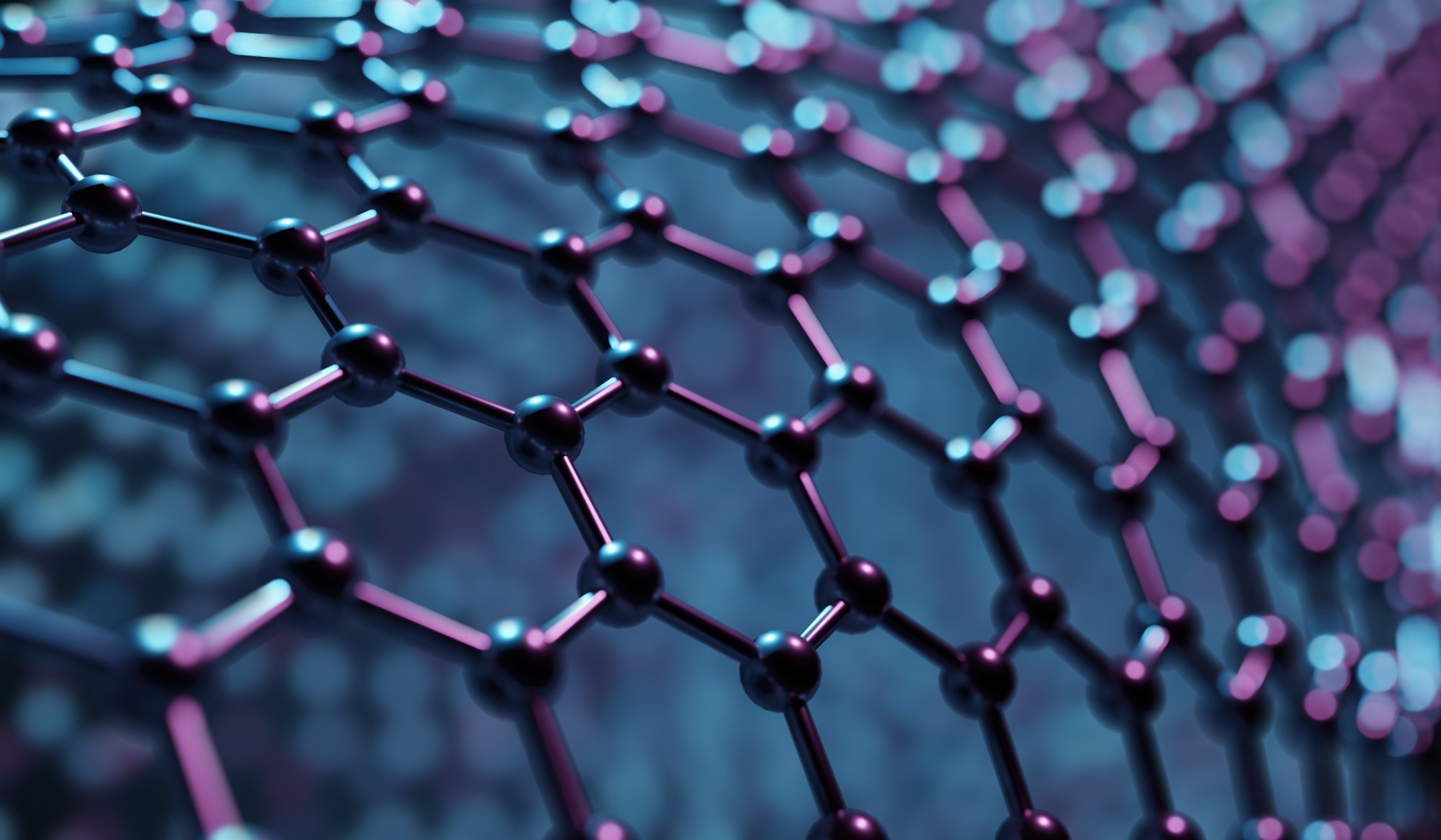

Researchers at the University of New South Wales (UNSW), Sydney, have recently developed a new method to create tiny 3D materials that would improve the efficiency of fuel cells and batteries and help make them more sustainable. The new innovative approach produces 3D nanoscale materials with novel physical and chemical properties, including high surface area and high conductivity.

Published in the journal Science Advances, the UNSW team describes how their synthetic concept delivers a new kind of high-performing electrocatalyst support. In other words, they show the possibility of growing a hierarchy of interconnected minuscule 3D structures that help facilitate energy conversions at the nanoscale.

Hydrogen Batteries and Fuel Cells

The aim of the study was to demonstrate how 3D nanostructures can be viable electrocatalytic support materials in fuel cells, including hydrogen batteries, as they possess a series of well-matched properties to do so.

Hydrogen-based fuel cells use the chemical energy of hydrogen to produce electricity cleanly and efficiently. When hydrogen is the fuel, the only major products are electricity, water, and heat. These kinds of fuel cells are special and valued in terms of the diversity of their potential applications; they have the potential to supply power for systems as large as a power plant and as small as a laptop computer.

The 3D nanostructures the UNSW team has developed have been engineered to reveal an increased number of atoms in the reaction environment. The idea is that this can support more efficient catalysis for more effective energy conversion.

3D Nanostructures and Catalysts for Fuel Cells

In standard metal catalysts, which are typically spherical, the majority of atoms remain concealed at the center of the sphere. This means a majority of the material goes to waste as few atoms are exposed at the surface and remain hidden from the reaction environment.

However, due to their unique geometries, the 3D nanostructures developed here would expose more of the atoms to the reaction.

If this is used in a fuel cell or battery, having a higher surface area for the catalyst means the reaction will be more efficient when converting hydrogen into electricity.

Professor Richard Tilley, Director of the Electron Microscope Unit, UNSW

This also means less material is required, which could, in effect, make for more environmentally compatible alt-fuel sources.

It will eventually decrease the costs as well, making energy production more sustainable and ultimately shifting our dependence further away from fossil fuels.

Professor Richard Tilley, Director of the Electron Microscope Unit, UNSW

Scientists have faced many challenges when replicating novel 3D structures with complex geometries using metals on the nanoscale. Previously, researchers demonstrated the capacity to assemble similar structures at the molecular level – but a “bottom-up methodology” was still required to achieve something similar at the nanoscale, Prof. Tilley said.

Thus, the UNSW team applied chemical synthesis during the development of the study to create nickel hexagonal crystal structured branches, which allowed them to construct the 3D hierarchal nanostructures around a crystal-structured core at 10-20 nm overall.

The result was a new metallic 3D nanostructure that had a greater surface area and conductivity potential than could be achieved using chemicals.

The UNSW team has set its sights on meeting the challenge in the next phase to modify the surface of nanostructured catalysts using platinum, a key but expensive catalytic material used extensively in fuel cells and fuel cell engines.

In the future, this could lead to improvements in the efficiency and sustainability of fuel cells, including hydrogen-based batteries using 3D nanoscale materials.

References and Further Reading

Gloag, L. et al. (2023) “Synthesis of hierarchical metal nanostructures with high electrocatalytic surface areas,” Science Advances, 9(2). Available at: https://www.science.org/doi/full/10.1126/sciadv.adf6075

Knight, B. (2023) New method for designing tiny 3D materials could make fuel cells more efficient, UNSW Newsroom. Available at: https://newsroom.unsw.edu.au/news/science-tech/new-method-designing-tiny-3d-materials-could-make-fuel-cells-more-efficient

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.