The force necessary to induce slipping across an entire frictional interface may escalate over an extended period under a steady load as a result of various combinations of creep, structural, or chemical alterations of the interface.

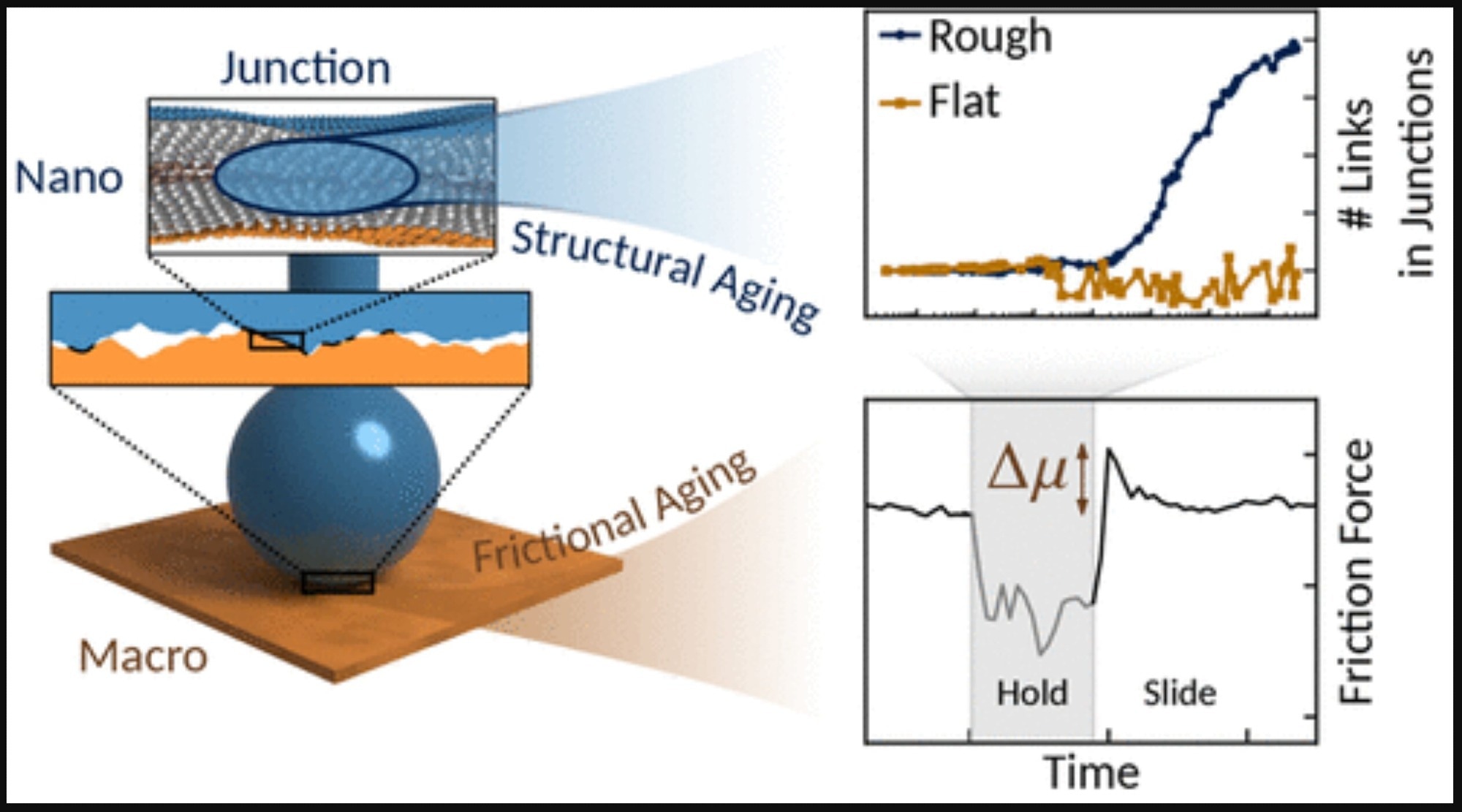

Graphical abstract. Credit: ACS Nano (2023). DOI: doi.org/10.1021/acsnano.2c08435

A paper published in the journal ACS Nano showed that for a frictional system solely experiencing structural aging, the macroscopic frictional response comes from the interaction among surface roughness and molecule movement inside adsorbed monolayers.

Friction: The Science of Surface Roughness

Friction impacts the behavior of every mechanical system and component, from geological fractures to the tips used in atomic force microscopy. Friction is closely linked with the surface roughness of natural and artificial materials and their contacting asperities.

On macroscopic levels, the static frictional force in amorphous materials shows a logarithmic rise with resting contact duration. However, the underlying molecular mechanisms that govern friction are not well understood.

Structural Aging and Rejuvenation

The force of friction is often defined at the macroscopic level by rate-and-state friction, which describes the force of friction concerning a state variable termed the averaged age of the microcontacts.

This variable accounts for both aging as well as rejuvenation, which are driven by a combination of geometrical, structural, and chemical changes at the contact interface.

Geometrical aging caused by creep is a critical process governing the macroscopic frictional response. Structural and chemical aging, on the other hand, have a role in enhancing "contact quality" or shear strength of junctions.

These mechanisms are closely linked to surface roughness and the memory length scale D0, which characterizes the rejuvenation rate, is controlled by molecular mechanisms within the contact junctions.

Molecular Mechanisms

Molecular processes regulate stiction peaks and their decay within the contact junctions rather than the sizes of the junctions themselves. In the absence of roughness, structural aging does not occur.

This shows that system aging may be explained by the ability of molecule tails to enter and exit contact junctions, which cannot occur if the surfaces are perfectly flat on the atomic level.

Integrating Macroscopic and Nanoscale Information

The study's goal was to shed light on the impact of surface roughness on nanometric friction processes and to incorporate this knowledge into a macroscopic model for friction.

The team used a model system consisting of two rough cobalt surfaces covered by a stearic acid lubricant. Using a combination of experiments and molecular dynamics simulations, they examined the specifics of the contact interface and established a unifying friction model.

The results emphasized the significance of surface roughness on the molecular level as well as molecular processes at the macroscopic level.

These nano and macroscale features were integrated into the research to create a multiscale theoretical model which accurately reproduces transient friction overshoots from experimental data.

Key Findings of the Study

The study provided important insights into the molecular processes behind structural, frictional aging and its transient frictional response by combining the findings of experiments and simulations of friction among fatty-acid monolayers deposited on rough surfaces.

By bridging the scale gap between nano and macroscale friction behavior, the team demonstrated that the stiction peak and its decrease are regulated by molecular processes inside contact junctions rather than the dimensions of the junctions themselves.

One of the authors of the paper, Jaafar El-Awady, commented on the salient features of the research by saying, "Our simulation allowed us to try things impossible in experiments, such as what would happen if the surfaces in contact were mathematically flat".

The study revealed that surface roughness was the primary cause of aging. According to Dr. Frérot, another member of the team, the models having no roughness did not show any aging.

Future Prospects

The concepts of the developed model are applicable to a broad range of frictional systems having surface roughness and coatings. This includes biomechanical systems like artificial or cartilaginous joints, where roughness may significantly influence appropriate function and longevity.

This study opens up new possibilities for understanding and controlling frictional systems at various scales, from the movement of geological faults to the sliding of atomic force microscopy tips, by considering the relationship between surface roughness and molecular mechanisms.

It can also have important implications for designing and optimizing tribological systems, such as lubricants, coatings, and surface treatments for reducing friction and wear.

Reference

Frérot, L., Crespo, A., El-Awady, J. A., Robbins, M. O., Cayer-Barrioz, J., & Mazuyer, D. (2023). From Molecular to Multiasperity Contacts: How Roughness Bridges the Friction Scale Gap. ACS Nano. Available at: https://doi.org/10.1021/acsnano.2c08435

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.