An international group of researchers is designing an inkable nanomaterial that they claim could one day turn into a spray-on electronic component for lightweight, ultra-thin, and flexible devices and displays.

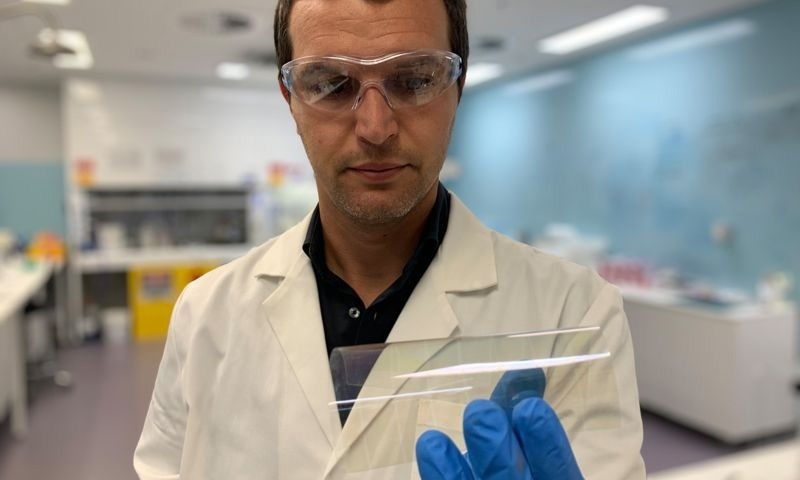

An ultra-thin coating of zinc oxide nanocrystals can be sprayed onto flexible substrates, such as plastic, that are resilient to flexing and bending, the team says. Image Credit: Royal Melbourne Institute of Technology University

As per the team, the material, zinc oxide, could be used in several components of future technologies along with computers and mobile phone due to its versatility.

Associate Professor Enrico Della Gaspera and Dr. Joel van Embden of RMIT University headed a team of international specialists to review capabilities, production strategies, and likely uses of zinc oxide nanocrystals in the journal Chemical Reviews.

The co-authors of this study are Professor Silvia Gross from the University of Padova in Italy and Associate Professor Kevin Kittilstved from the University of Massachusetts Amherst in the United States.

Progress in nanotechnology has enabled us to greatly improve and adapt the properties and performances of zinc oxide by making it super small, and with well-defined features.

Prof. Enrico Della Gaspera, School of Science, Royal Melbourne Institute of Technology University

Tiny and versatile particles of zinc oxide can now be prepared with exceptional control of their size, shape, and chemical composition at the nanoscale. This all leads to precise control of the resulting properties for countless applications in optics, electronics, energy, sensing technologies, and even microbial decontamination.

Dr Joel van Embden, School of Science, Royal Melbourne Institute of Technology University

Sky’s the Limit with Spray-On Electronics

The zinc oxide nanocrystals could be formulated into ink and deposited as an ultra-thin coating. Although the process is similar to airbrush painting or ink-jet printing, the coating is hundreds to thousands of times thinner when compared to a traditional paint layer.

“These coatings can be made highly transparent to visible light, yet also highly electrically conductive—two fundamental characteristics needed for making touchscreen displays,” Della Gaspera added.

The nanocrystals could also be deposited at a low temperature, which allows coatings on flexible substrates, like plastic, that are resilient to bending and flexing, the team says.

The research group is prepared to work with the industry to discover likely applications with their techniques to produce these nanomaterial coatings.

What is Zinc Oxide, and How Can it Be Used?

In the Earth’s crust, zinc is an abundant element, and it is more abundant than many other technologically relevant metals, for example, nickel, tin, lead, copper, tungsten, and chromium.

“Zinc is cheap and widely used by various industries already, with global annual production in the millions of tonnes,” van Embden stated.

“Zinc oxide gained a lot of interest in the 1970s and 1980s due to progress in the semiconductor industry. And with the advent of nanotechnology and advancement in both syntheses and analysis techniques, zinc oxide has rapidly risen as one of the most important materials of this century,” added Della Gaspera.

Also, zinc oxide is biocompatible, safe, and present in products like cosmetics and sunscreens.

Possible applications, apart from bendable electronics, that could employ zinc oxide nanocrystals are given below:

- Antifungal and antibacterial agents

- self-cleaning coatings

- electronic components in light emitting devices (LED) and solar cells

- sensors to detect ultraviolet radiation

- sensors that could be employed to detect toxic gases for industrial, residential, and environmental applications

- transistors, which are miniature components that are the foundation of modern electronics and control electrical signals

Next Steps

Della Gaspera stated that scaling up the approach of the team from the laboratory to an industrial environment would require working with the appropriate partners.

“Scalability is a challenge for all types of nanomaterials, zinc oxide included. Being able to recreate the same conditions that we achieve in the laboratory, but with much larger reactions, requires both adapting the type of chemistry used and engineering innovations in the reaction setup,” he added.

Besides these scalability concerns, the team has to resolve the lack of electrical conductivity that nanocrystal coatings possess more than that of industrial benchmarks, which depend on more complicated physical depositions.

The core structure of the nanocrystal coatings, which facilitates more flexibility, restricts the coating’s capacity to conduct electricity successfully.

“We and other scientists around the world are working towards addressing these challenges and good progress is being made,” Della Gaspera added.

“I am confident that, with the right partnership, these challenges can be solved,” Della Gaspera stated.

Journal Reference

van Embden, J., et al. (2022). Colloidal Approaches to Zinc Oxide Nanocrystals. Chemical Reviews. doi.org/10.1021/acs.chemrev.2c00456.