Artificial nanostructures created specifically to modify the properties of light are known as metamaterials. However, an efficient production that would enable mass commercialization of these nanostructures has yet to be realized.

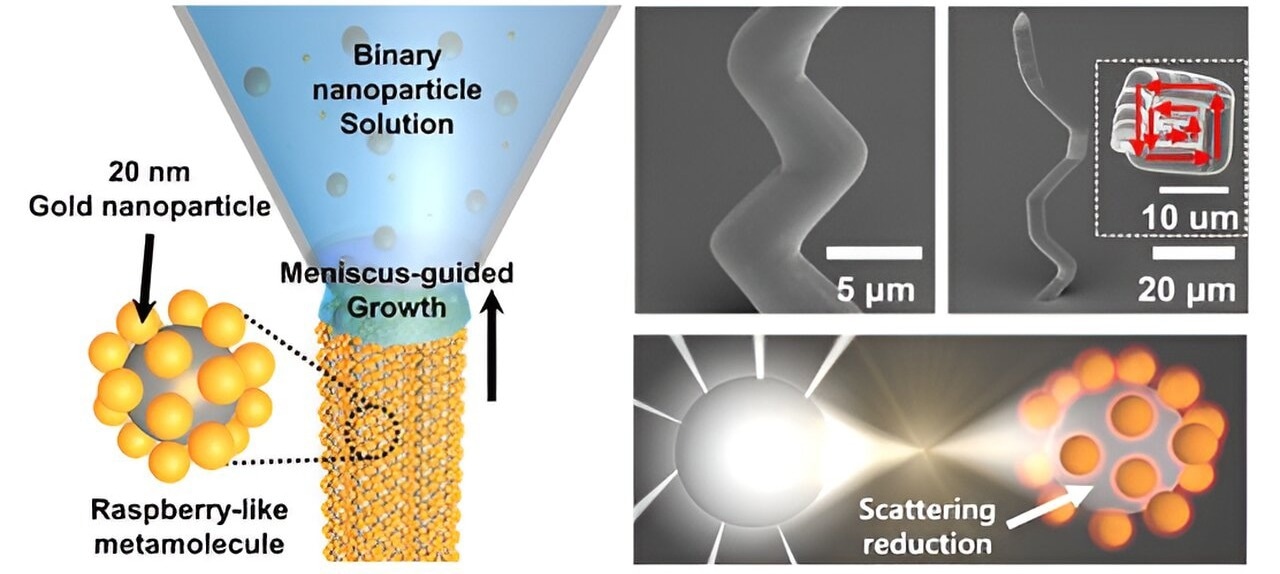

3D co-assembly of free-standing and freeform metamaterials using micropipette tips showcasing scattering reduction. Image Credit: POSTECH

3D co-assembly of free-standing and freeform metamaterials using micropipette tips showcasing scattering reduction. Image Credit: POSTECH

A research group at Pohang University of Science and Technology (POSTECH) headed by Ph.D. candidate Hongyoon Kim from the Department of Mechanical Engineering, researcher Won-Geun Kim, and Professor Junsuk Rho from the Department of Chemical Engineering and Mechanical Engineering has developed a method to address this commercialization problem.

Using co-assembly technology and three-dimensional nano printing, their approach moves metamaterials one step closer to being made commercially available. Their findings were published in Small.

Traditionally, metamaterials are created by layering physical and chemical layers onto materials like silicon and resin (plastic), then lithography. Regrettably, this process is expensive and limiting in terms of materials that can be used. As a result, the academic community has recently turned its emphasis toward manufacturing metamaterials by particle assembly rather than the costly procedure of surface shaving.

The research team used a combination of three-dimensional nano printing and co-assembly approaches in their study. Initially, they used silica (glass) and gold nanoparticles of different sizes to create raspberry-like metamolecules. These raspberry-like structures were then piled on top of one another, culminating in the successful fabrication of millimeter-sized metamaterials.

Essentially, instead of using more expensive and traditional ways, the research team has developed a process technology that allows the cost-effective synthesis of metamaterials in specific shapes.

The experiments conducted showcased the light-controlling capabilities of metamaterials generated through the team’s process. Notably, there was a significant reduction in scattered light within the visible region. This research marks the first instance of verifying the optical properties of metamolecules in solution using millimeter-sized structures.

This method does not require specialized equipment for verification because the results can be seen with the unaided eye or under a basic microscope setup. The scientists also adjusted the proportion of silica to gold nanoparticles in the metamaterial to obtain precise control over the optical characteristics.

This breakthrough enables the design and implementation of free-form nanophotons, surpassing the limitations of existing metamaterial fabrication processes. The versatility of this technology affords a wide range of material choices including quantum dots, catalyst particles, and polymers, making it applicable to diverse fields from sensors to displays in addition to metamaterial research.

Junsuk Rho, Professor, Department of Mechanical Engineering and Chemical Engineering, Pohang University of Science and Technology

Journal Reference:

Kim, W.-G., et al. (2023) Freestanding, Freeform Metamolecule Fibers Tailoring Artificial Optical Magnetism. Small. doi:10.1002/smll.202303749