We live in a society where the demand for advanced materials in commercial industries places significant pressure on manufacturing industries. Purdue University's latest laser technologies, spearheaded by Professor Gary Cheng, form the basis of patented methodologies suitable for broad applications, from producing semiconductor oxide thin films vital for consumer electronics to the enhancement of metals used in extreme environmental conditions.

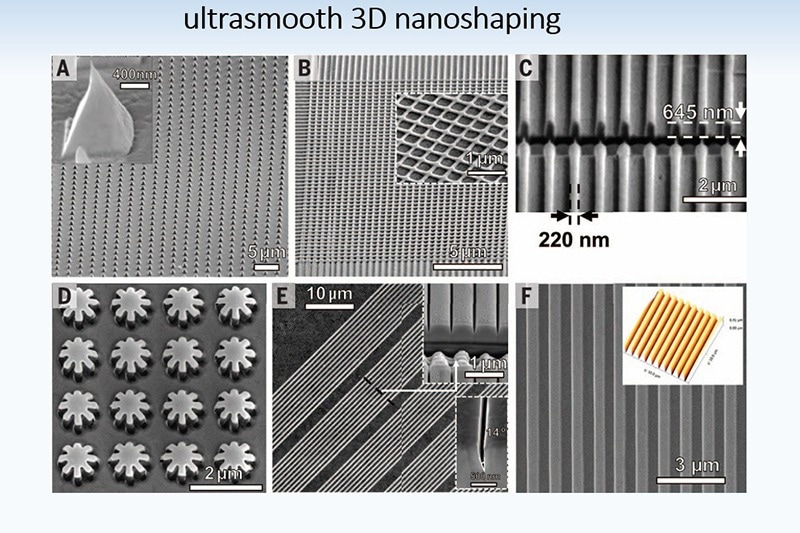

Gary Cheng, professor in Purdue University’s School of Industrial Engineering, has developed several patented laser techniques, including a nanomanufacturing platform to achieve ultrafine-scale, 3D manipulation of metals and nanomaterials. (Image provided by Gary Cheng)

These innovations have been published in a range of high-impact journals, including Nature Communications, Science and Science Advances, and promise to bolster the performance of materials in sectors like renewable energy and aerospace and also offer new avenues in the ultra-precise manipulation of nanomaterials.

Revolutionizing Nanotechnology with Laser-Based Techniques

Notable, Professor Cheng's team has developed a state-of-the-art laser-based nanomanufacturing platform that is capable of manipulating metals and nanomaterials at an ultrafine scale of less than 5 nanometers, allowing for 3D manipulation with exceptional precision.

The technology has already shown its potential in diverse fields, such as plasmonics and quantum computing, by enabling the adjustment of properties in materials like graphene and the precise spacing in quantum dots and nanowires.

Using a laser to manipulate the force and temperature on nanomaterials at an ultrafine scale creates opportunities for 3D micro/nano-component manufacturing, including patterning and integration of 0D-2D heterostructured nanomaterials.

Professor Cheng, Professor of Industrial Engineering, Purdue University

The group hopes that such developments will usher in new possibilities for developing compact devices in various high-tech fields.

Enhancing Thin Films and Nano-Inks with Laser Assistance

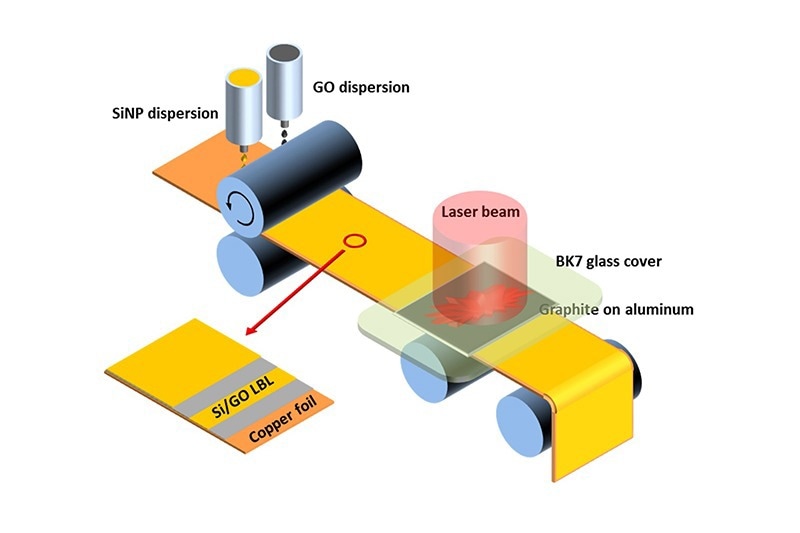

The team's novel approach to processing thin films and nano-inks offers a significant upgrade over traditional methods. Their technique, which combines pulsed laser deposition with laser annealing, results in semiconductor oxide thin films with superior structural and optoelectronic properties. This advancement is particularly crucial for the production of transparent conducting oxide films used in next-generation liquid crystal and organic LED displays.

"The traditional material to create TCO films has been indium tin oxide," states Cheng. "We're exploring semiconductor oxides like gallium-doped zinc oxides to surpass the performance and production rate limitations of current methods." The team's approach also integrates roll-to-roll printing of nano-inks with laser annealing, opening the door for mass production of high-quality, low-defect thin films.

Purdue professor Gary Cheng and his colleagues have manufactured semiconductor oxide thin films by combining pulsed laser deposition with laser annealing to achieve better structural and optoelectronic properties than traditionally manufactured films. (Image provided by Gary Cheng)

Innovative Laser Shock Peening for Enhanced Metal Durability

Professor Cheng's team has also redefined laser shock peening with their novel nanostructure-integrated technique (nLSP). This innovation overcomes the limitations of traditional laser shock peening by introducing controlled nanostructures during the process, thereby enhancing the stability and mechanical properties of metals.

Our method significantly improves the efficiency of nLSP on alloys like aluminum and titanium, introducing nanostructures that bolster the metal's mechanical properties and stability under extreme conditions.

Professor Cheng, Professor of Industrial Engineering, Purdue University

This breakthrough has significant implications for industries like aerospace and naval engineering, where material reliability is critical.

Funding and Commercialization Prospects

Supported by prestigious institutions like the National Institute of Standards and Technology and the National Science Foundation, Cheng's research is well-positioned for commercialization. With patents already in place, these technologies hold great promise for industry partners looking to advance material capabilities in various sectors.