A team of researchers from the Korea Research Institute of Standards and Science has developed an incredibly sensitive toxic gas sensor that rivals existing devices. At room temperature, this sensor has ultra-high sensitivity and low power consumption, enabling it to precisely monitor nitrogen dioxide (NO2), a hazardous chemical in the atmosphere. It has applications in many different domains, including identifying leftover gases in the process of making semiconductors and studying electrolysis catalysts.

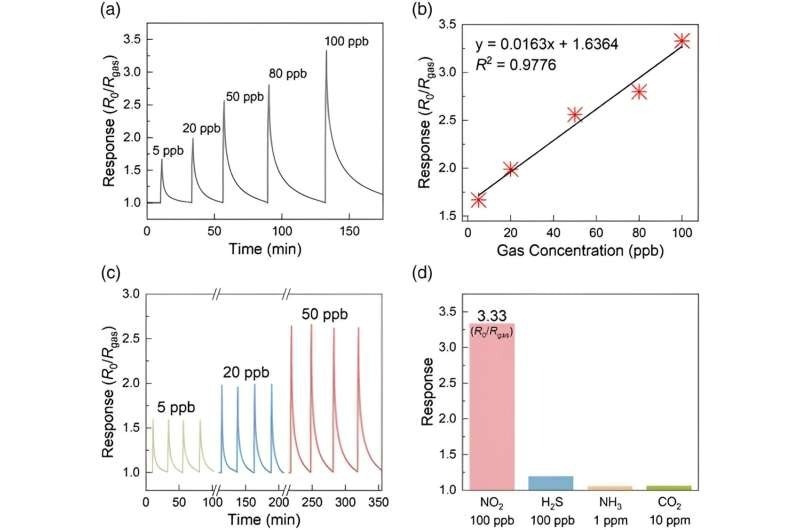

Performance evaluation results of the ultra-sensitive gas sensor developed by KRISS. Image Credit: Korea Research Institute of Standards and Science (KRISS)

Performance evaluation results of the ultra-sensitive gas sensor developed by KRISS. Image Credit: Korea Research Institute of Standards and Science (KRISS)

NO2, a byproduct of high-temperature fossil fuel combustion and largely released by automotive exhaust or manufacturing smoke, contributes to an increase in mortality due to air pollution. The yearly average content of NO2 in the air in South Korea is restricted by presidential order to be 30 ppb or below. Highly sensitive sensors are thus necessary to detect gases at extremely low concentrations.

The emergence of high-tech sectors, such as semiconductor production, has led to an increase in the usage of hazardous gases that pose a risk to human health. Although semiconductor-type sensors have been used in some companies and labs for safety purposes, their poor response sensitivity prevents them from detecting harmful gasses that could even be detectable by the human nose. They ultimately take a lot of energy since they have to run at high temperatures to maximize the sensitivity.

Compared to traditional sensors, the newly developed sensor, a next-generation semiconductor-type poisonous gas sensor based on advanced materials, shows noticeably better performance and usability. The novel sensor can detect NO2 60 times more sensitively than previously reported semiconductor-type sensors due to its exceptional sensitivity to chemical reactions.

Furthermore, the innovative sensor uses very little power while working at room temperature, and its ideal semiconductor production technique allows for large-area synthesis to occur at low temperatures, which lowers the cost of fabrication.

KRISS produced a substance called MoS2 nanobranch, which holds the secret to the technology. The sensitivity is increased since this material is produced in a 3D structure that resembles tree branches, as opposed to the typical 2D flat shape of MoS2.

Its ability to synthesize materials uniformly across a wide surface area is enhanced by the ability to produce 3D structures without the need for extra procedures by modifying the carbon ratio in the raw material.

Through practical demonstration, the KRISS Semiconductor Integrated Metrology Team has shown that its gas sensor can identify NO2 in the ambient at as low as 5 parts per billion. With an estimated detection limit of 1.58 ppt, the sensor has the greatest sensitivity in the world.

This accomplishment allows for low-power, accurate NO2 in the atmospheric monitoring. The sensor delivers great resolution along with time and money savings. With its ability to measure real-time changes and identify yearly average amounts of NO2, it is anticipated to further study improving atmospheric conditions.

This method also has the capability to change the electrochemical characteristics by varying the carbon concentration of the raw material during the material production step. This could be used to create sensors that can identify gases other than NO2, including byproduct gases generated during the production of semiconductors.

The material’s exceptional chemical reactivity can also be used to improve the efficiency of electrolysis catalysts to create hydrogen.

This technology, which overcomes the limitations of conventional gas sensors, will not only meet government regulations but also facilitate precise monitoring of domestic atmospheric conditions. We will continue follow-up research so that this technology can be applied to the development of various toxic gas sensors and catalysts, extending beyond the monitoring of NO2 in the atmosphere.

Dr. Jihun Mun, Senior Researcher, Korea Research Institute of Standards and Science

Journal Reference:

Song, J., et. al. (2023) MOCVD of Hierarchical C-MoS2 Nanobranches for ppt-Level NO2 Detection. Small Structures. doi:10.1002/sstr.202200392