The waveguide, a metal tube used to direct radio waves, is a critical component of satellites that enable communications. It is also one of the heaviest payloads that satellites transport into orbit. As with any space technology, lowering weight means using less expensive and greenhouse gas-producing fuel to launch a rocket or carrying more devices to space.

Researchers from Drexel University and the University of British Columbia have demonstrated that polymeric waveguide components coated in MXene ink can perform as well as their metal counterparts and could provide a lightweight alternative for future space technology. Image Credit: Drexel University/University of British Columbia

Researchers from Drexel University and the University of British Columbia have demonstrated that polymeric waveguide components coated in MXene ink can perform as well as their metal counterparts and could provide a lightweight alternative for future space technology. Image Credit: Drexel University/University of British Columbia

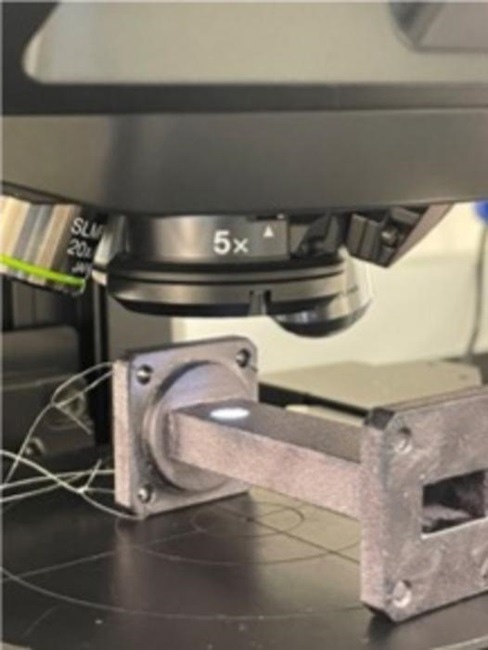

To reduce the weight, researchers from the University of British Columbia and Drexel University are developing and testing a waveguide composed of 3D-printed polymers covered with conductive nanomaterial MXene.

The team discussed the possibility of employing MXene coatings to give lightweight, nonconductive components electrical conductivity, a feature that is given up in additive manufacturing with polymer materials like plastics. Their study was recently published in the journal Materials Today.

In spaceflight applications, every extra gram of weight counts. MXene materials provide one of the thinnest possible coatings — their flakes have a thickness of a few atoms — that can create a conductive surface, so we see great potential in using MXenes to treat additive manufactured components made of polymers that have complex shapes.

Yury Gogotsi, PhD, Distinguished University and Bach Professor, College of Engineering, Drexel University

Waveguides operate as microwave conduits. They route the waves to receivers while maintaining the signal’s strength. Waveguides in a microwave oven heat the food; on a satellite, they transport high-quality communications between different components within and between satellites, as well as between satellites and Earth.

Waveguides, like the complicated network of pipes that thread their way through a home, are created in a variety of forms to fit into constrained places. They can range from simple, straight channels to complicated formations like a labyrinth.

Waveguides can be as basic as a straight, rectangular channel or they can morph into shapes resembling a 'crazy straw,' with bends and twists. The real game-changer, however, is the advent of additive manufacturing methods, which allow for more complex designs that can be difficult to produce with metals.

Mohammad Zarifi, Associate Professor, Drexel University

While any hollow tube can serve as a rudimentary “waveguide,” those that transmit electromagnetic waves, such as microwave ovens and telecommunications equipment, must be composed of a conductive material to maintain transmission quality. These waveguides are commonly built of metals like silver, brass, and copper. In satellites, aluminum is a lighter-weight material.

Based on their earlier findings that MXenes can block and channel electromagnetic radiation, the Drexel researchers—who first discovered MXenes in 2011 and have since led their research and development—suggested the 2D nanomaterials would be a good candidate as a coating for the plastic waveguide components.

Our MXene coating emerged as a strong candidate for this application because it is highly conductive, functions as an electromagnetic shield and can be produced simply by dipping the waveguide in MXenes dispersed in water. Other metallic paints have been tested, but due to the chemicals used to stabilize their metallic ingredients, their conductivity suffers in comparison to MXenes.

Lingyi Bi, PhD Student, Drexel University

Furthermore, the researchers noted that because of the chemical structures’ compatibility, the MXene coating adhered to the 3D-printed nylon waveguides exceptionally well. To see if MXene could completely cover their interior, the team dip-coated lightweight guides in a variety of sizes and forms, including resonator-shaped, bending, straight, and twisted guides.

The MXene-coated nylon waveguides weigh around eight times less than the typical aluminum ones now in use, and the MXene coating added only a tenth of a gram to the overall weight of the components.

Most significantly, the MXene waveguides worked almost as well as their aluminum counterparts, with an 81% efficiency in steering electromagnetic waves between two terminals after only one cycle of dip coating, representing just a 2.3% reduction in performance compared to aluminum.

The researchers proved that they could increase this transmission parameter by altering the layers of coating or the size of MXene flakes, achieving a maximum transmission efficiency of 95%.

When the transmission was adjusted to the various frequency bands—such as those now in use in low-Earth orbit satellite communications—and had a high enough input power for these transmissions, the performance remained stable. In addition, it did not substantially deteriorate after three months, demonstrating the coating’s longevity.

Roman Rakhmanov, a doctoral candidate at Drexel who participated in the study, added, “The MXene-coated waveguides still need to go through extensive testing and be certified for space use before they can be used on satellites. But this finding could be an important step toward the next generation of space technology.”

Gogotsi’s group intends to carry out more research on MXene coatings in areas where having a metal component substitute might be advantageous.

Gogotsi concluded, “These promising results suggest that MXene-coated components could be a viable lightweight replacement for waveguides used in space. We believe that the coatings could also be optimized for transmissions of varying frequencies and applied to a variety of additive-manufactured or injection-molded polymer components, providing a lightweight and low-cost alternative to metals in a number of terrestrial applications as well.”

Journal Reference:

Niksan, O., et. al. (2024) MXene guides microwaves through 3D polymeric structures. Materials Today. doi:10.1016/j.mattod.2023.12.013.