A multidisciplinary group of researchers at Cornell University has discovered a novel method for using the antibacterial and antioxidant characteristics of lawsone, a botanical compound, to create cotton bandages coated with nanofibers that prevent infection and promote faster wound healing.

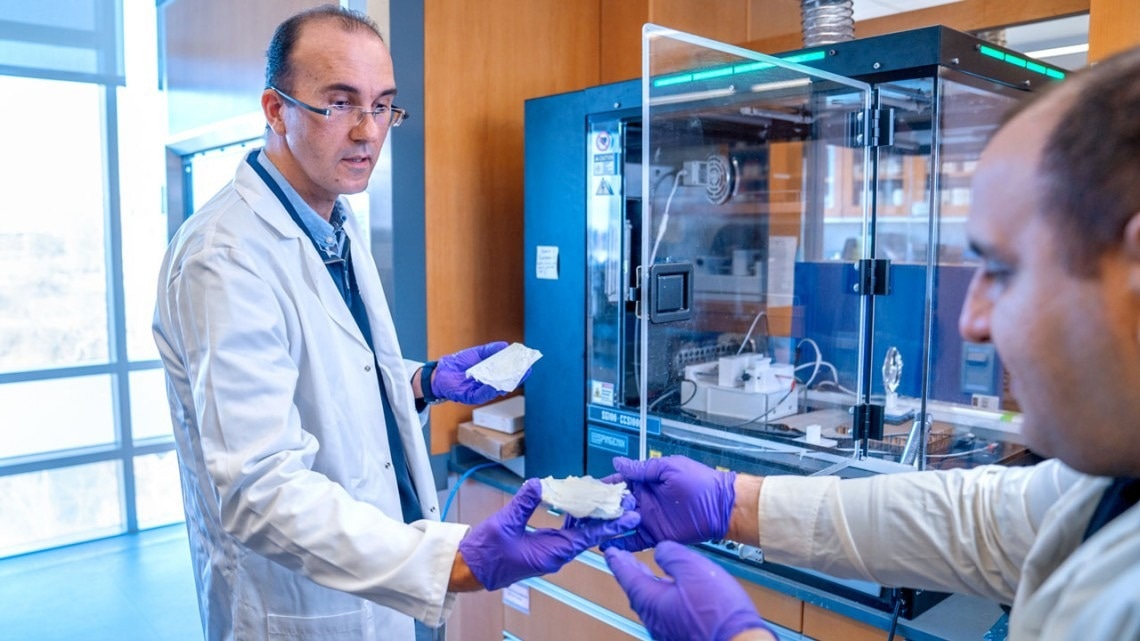

Tamer Uyar (left), associate professor in Human Centered Design and doctoral student Mohsen Alishahi work on developing nanofiber-coated cotton bandages. Image Credit: Darcy Rose/Provided

Tamer Uyar (left), associate professor in Human Centered Design and doctoral student Mohsen Alishahi work on developing nanofiber-coated cotton bandages. Image Credit: Darcy Rose/Provided

Their results, released in the International Journal of Pharmaceutics, are particularly significant in light of the rising incidence of bacteria resistant to several drugs.

One of the most popular types of wound dressings is cotton gauze since it is affordable, easily accessible, cozy, and biocompatible. It does not, however, combat infection or aid in healing.

Cotton alone cannot provide an answer for these complications – it needs to be biofunctionalized.

Mohsen Alishahi, Study Lead Author and Graduate Student, Cornell University

The lab's director, Tamer Uyar, an associate professor of HCD, noted that creating functional fibers from sustainable materials and investigating their possible uses in drug delivery systems and medical textiles is one of the lab’s primary research priorities.

For this study, Alishahi, Uyar, and Ph.D. student Mahmoud Aboelkheir employed lawsone, a red-orange chemical found in henna leaves with antioxidant, anti-inflammatory, and antibacterial effects, to improve cotton performance.

Lawsone has been demonstrated to help wounds heal faster. However, it is difficult to dissolve in a solution and is not easily absorbed by the body. To overcome these constraints, the scientists employed cyclodextrins, a class of natural oligosaccharides derived from starch, to form an inclusion compound that bound the lawsone molecules within it.

They then employed electrospinning equipment to create a homogenous nanofibrous coating from the lawsone-cyclodextrin solution and captured it on a nonwoven cotton pad. They discovered that the experimental dressing had much better antioxidant activity—suggesting quicker wound healing—than pure lawsone, owing to the improved solubility of the lawsone caused by cyclodextrin inclusion and the nanofibrous system's high surface-to-volume ratio.

The NanoFibTex team then collaborated with Craig Altier, professor of population medicine and diagnostic sciences, and Rimi Chowdhury, senior research associate, both from the College of Veterinary Medicine, to evaluate the dressing’s biological features.

The experimental dressing demonstrated outstanding antibacterial activity against both gram-negative and gram-positive bacterial species, successfully eliminating E. coli and staph bacteria during testing.

The prolonged overuse of synthetic antibiotics in high concentrations has contributed to the rise of the deadly epidemic of multidrug-resistant microbes. So the use of natural and potent anti-bacterials such as lawsone may serve as an alternative to synthetic anti-bacterials.

Tamer Uyar, Study Corresponding Author and Associate Professor, Fiber Science, Cornell University

Alishahi stated, “Wound dressings should provide a suitable environment for facilitating healing and preventing infection. Using totally natural materials such as cotton, cyclodextrin and lawsone, this dressing can facilitate both as it has comprehensive antioxidant and anti-bacterial activity.”

Alishahi stated that the dressing would be especially beneficial for chronic wounds prone to infection, such as diabetic ulcers and burns. More regular wounds would benefit from the antioxidant and anti-inflammatory characteristics, which would help to reduce scar formation.

Alishahi concluded, “I am familiar with the complications patients face due to the lack of suitable dressings. My ultimate goal is to develop a dressing that can overcome these difficulties for them. This work opens doors to creating medical textiles that are good for the environment and great for healing.”

Cotton Incorporated supported this research.

Journal Reference:

Alishahi, M., et. al. (2024) Functionalization of cotton nonwoven with cyclodextrin/lawsone inclusion complex nanofibrous coating for antibacterial wound dressing. International Journal of Pharmaceutics. doi:10.1016/j.ijpharm.2024.123815