Quantum Science, the infrared quantum dot (QD) technology company, has boosted the stability of its lead-free QD inks to almost a year, granting a long-life solution for research and development.

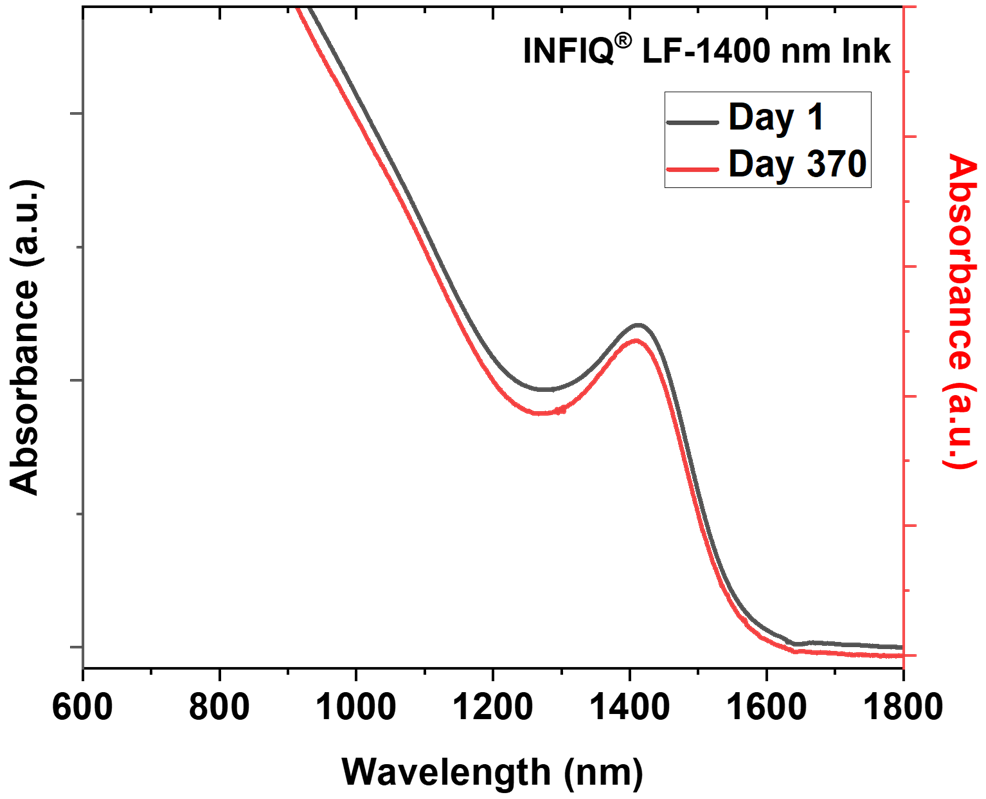

Absorption spectra of INFIQ® Lead-free Ink demonstrating up to 1 year stability in-terms of optical absorption properties. Image Credit: Quantum Science

Absorption spectra of INFIQ® Lead-free Ink demonstrating up to 1 year stability in-terms of optical absorption properties. Image Credit: Quantum Science

Recent breakthroughs from Quantum Science’s lead-free (LF) focus team have transformed the stability of its INFIQ® LF-QD inks both at wavelengths of 1,100 nm and 1,400 nm.

Extensive testing has shown that INFIQ® LF-QD inks can remain stable for up to a year, both in terms of their optical characteristics and device performance. No shifts in optical absorption peaks, peak properties, or device efficiency were observed during this period.

This overcomes challenges that most LF-QD inks experience in maintaining stability over long periods due to the reduction in ligand size compared with QD materials, supporting research and development by extending the shelf life of QD solutions.

The INFIQ® LF-QD inks have also been proven to work on silicon wafers, facilitating high-scale short-wave infrared (SWIR) image sensor manufacturing as less ink is required to coat larger wafers.

LF-QD inks are instrumental to bringing SWIR capability into markets where traditional heavy-metal based QDs are restricted, such as consumer electronics and medical devices.

Dr Hao Pang, CEO and Founder of Quantum Science, said: “At Quantum Science, we are pushing the boundaries of SWIR technology and this latest achievement by our world-leading team in LF-QD formulation is a testament to our vision of making SWIR imaging and sensing accessible to all. Boosting the stability of LF-QD inks at 1,400 nm and 1,100 m to almost a year is a landmark moment for the industry, demonstrating the potential of this technology and our drive to keep building on performance.

“New applications for LF-QD inks are still emerging as research and development professionals discover use cases for them in consumer electronics, medical devices, and much more. The ability to store LF-QD inks for longer periods will support research into new applications, bringing this world-changing technology into products we use every day.”