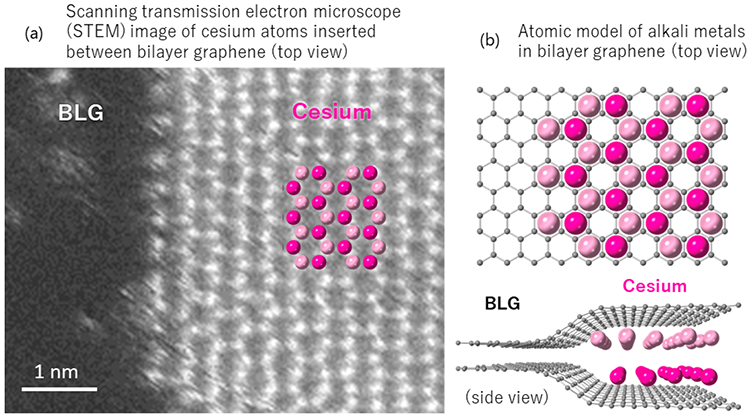

Researchers at AIST have created a method to introduce alkali metals into the graphene interlayers, working with researchers from Osaka University, Tokyo Polytechnic University, Kyushu University, and National Tsing Hua University. A single sheet of carbon atoms organized in a hexagonal lattice is called graphene. The atomic configuration of the implanted alkali metal atoms, which is a hexagonal close-packed bilayer structure, has been successfully observed by them.

Alkali metals form a hexagonal close-packed bilayer when inserted into bilayer graphene. Image Credit: National Institute of Advanced Industrial Science and Technology (AIST)

Alkali metals form a hexagonal close-packed bilayer when inserted into bilayer graphene. Image Credit: National Institute of Advanced Industrial Science and Technology (AIST)

The performance of rechargeable batteries has a significant impact on the driving range of electric vehicles and smartphone usage time. Improving the performance of these electronic gadgets is achievable if rechargeable batteries can amass more electrical power.

Graphite, the electrode material used in batteries, is made up of multilayers of graphene with alkali metals sandwiched between the layers to enable electron flow during charging and discharge. Achieving a high density of alkali metal storage between graphene layers could enhance electric capacity.

X-Ray and electron diffraction experiments have made it generally known over the past century that graphene interlayers can only hold one layer of alkali metal. The theoretical charging limit is the number of single-layer alkali metal atoms that fill each layer to capacity.

There have not been any studies that directly observe the atomic arrangement of interlayer alkali metals, though, to confirm whether graphene layers can only hold a single layer of alkali metal atoms or if other methods can produce multiple layers or a higher density of alkali metals.

A method for introducing dense alkali metals in between graphene layers has been devised by the researchers. They have successfully observed the arrangement structure of alkali metal atoms between the graphene layers using a high-performance low-voltage (60 kV) electron microscope.

Due to their flexible interlayer spacing, alkali metals are densely packed in a two-layer structure in surface layer graphite and bilayer graphene. This makes it possible to inject about twice as many alkali metals. It is anticipated that graphene with two layers of alkali metal insertion would function as an electrode material to increase the capacity of secondary alkaline ion batteries.

Background

Japan is making significant strategic investments in the development of rechargeable batteries for use in electric cars and information technology to decarbonize society and create a sophisticated information network that links people, products, and services.

The crucial challenge of decreasing battery weight and increasing battery capacity is one of the elemental technologies required to improve the performance of rechargeable batteries. Carbon layers make up graphite, a strong and lightweight electrode material.

Lithium and other alkali metal ions undergo electron transfers throughout the charging and discharging process. Increasing the amount of alkali metal ions in the electrodes is essential to boosting the capacity of rechargeable batteries.

Nevertheless, atomic-level observations of the electrode structure have proven difficult to accomplish using conventional methods of measurement and assessment. Furthermore, there have been very few design instructions available for efficiently introducing alkali metal ions into graphene layers.